Carbon Axis XCell strengthens AFP capabilities at Compositadour

New robotic cell will expand testing, prototyping and pre-series production for industries looking to automate composites preforming.

Compositadour (Bayonne, France) has acquired an XCell robotic automated fiber placement (AFP) solution from Carbon Axis (La Rochelle, France). In use since December 2020, the XCell machine allows for the automation of 2D and 3D composites preforms (maximum part size: 1 meter x 0.5 meter x 0.5 meter). Housed within an enclosed and temperature-regulated environment, XCell ensures reliable manufacturing in a small footprint and high repeatability during the process.

XCell system components

The XCell is a compact and accessible “Plug & Produce” AFP solution that allows fast and easy integration into any workshop. The AFP head, the XPlace, has a unique patented design optimized for preforming small parts. The XPlace installed at Compositadour is equipped with a temperature-controlled infrared heating source and features angled fiber cutting as well as double-width or double-thickness material placement.

The production unit is capable of processing thermoset and dry fiber materials packaged on industry-standard 3-inch bobbins. These materials are stored in a tension-controlled creel system that increases storage capacity and enables multi-material placement (with an optional second AFP head).

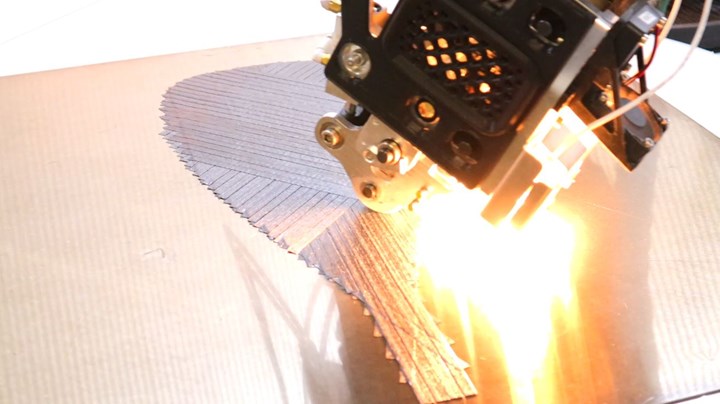

XCell AFP creating a 3D preform. Photo Credit: Carbon Axis

Designed for easy operation, the XCell is controlled through a touchscreen HMI (human-machine interface) and comprises a small-payload KUKA industrial robot that allows for the manufacturing of complex 3D geometries as well as flat laminates.

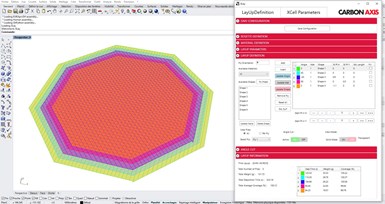

XLay software interface integrated inside Rhino 7.0 CAD/3D modeling software for manufacturing. Photo Credit: Carbon Axis.

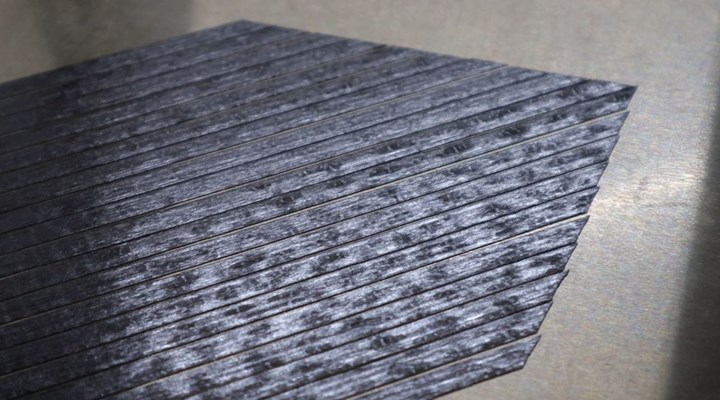

Automated preforming of a sports product application. Photo Credit: Carbon Axis

XLay is Carbon Axis’ dedicated all-in-one AFP software, which simplifies the programming of the machine from part design, layup definition and robot trajectory simulation to machine code export within a single software environment.

The machine will be used for testing, industrial case studies, prototyping and pre-series manufacturing of small composite applications at Compositadour. “Our first developments concern the manufacturing of 2D or 3D preforms for aeronautics applications,” notes Françis Sedeilhan, director at Compositadour.

Automating composite repair patches

“The angle cut technology is a real advantage compared to other AFP solutions,” Sedeilhan continues. “This enables manufacturing net-shape preforms that can be used to automate the repair of composites parts, for example, by manufacturing patches that fit perfectly within the machined steps of a stepped scarf repair. Automating this operation with the Carbon Axis XCell increases the quality of the repair by decreasing the risk of defects introduced with manual labor on such tricky operations, and without adding cost thanks to the low investment of the machine and ease of use for an operator.”

XCell’s patented angle cut technology brings new net shape possibilities for AFP. Photo Credit: Carbon Axis.

Related Content

-

Glass fiber-reinforced Akulon RePurposed recyclate enables Ahrend sustainable office chair

Envalior 30% glass fiber-reinforced Akulon RePurposed material helps Ahrend achieve lighter task chair with closed-loop value chain and reduced emissions.

-

Time Bicycles to modernize composite bicycle manufacturing

With the aid of KraussMaffei, Clemson University and SC Fraunhofer USA Alliance, Time anticipates a transition to HP-RTM for more efficient carbon fiber bike frame manufacture, plus a new facility in South Carolina.

-

KraussMaffei and partners develop sustainable, safe and stylish children’s bike

The Lion Bike is a German-made, injection molded bicycle with 40% recycled carbon fibers with zero scrap and enabling 67% lower CO2 emissions during production.