Reinforcements

The evolution of additive composites

Defining additive composites manufacturing and how its merge with conventional processes is providing new solutions and a path forward.

Read MoreMcMurtry Automotive reveals composites-intensive, fully electric Spéirling demonstrator vehicle

There are two things we know for sure about this one-seat vehicle: it’s fast, and there are plenty of composites involved.

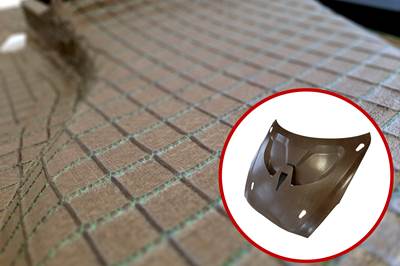

Read MoreComposites Evolution, Bcomp launch Evopreg ampliTex flax-epoxy prepregs

Compatible with Bcomp’s powerRibs reinforcement grid, the family of natural fiber materials drives enhanced stiffness, lightweight and a reduced footprint for motorsports and high-performance automotive applications.

Read MoreAirbus delivers first A350 completed in China

More efficient fuel burn, a carbon fiber fuselage and wings and a quiet cabin take A350 orders well over 900.

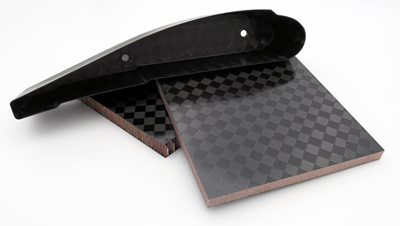

Read MoreHexPly M901 prepreg accelerates product development cycles

Hexcel’s HexPly M901 prepreg system reportedly reduces production time of composite leaf springs.

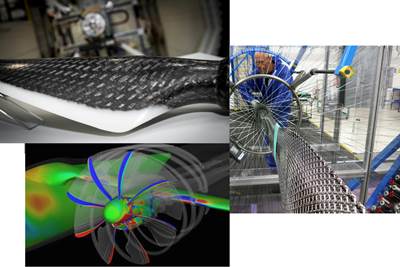

Read MoreDigiProp positions Dowty Propellers and its customers for sustainable, next-generation platforms

AMRC aids R&D program including foam thermoforming, complex braiding, thermoplastics and digital twin/thread for higher performance, lower weight with first applications in process.

Read MoreToray Composite Materials America launches flexible, adaptive 2700 prepreg system

Particularly geared toward emerging aerospace programs, the epoxy-based meets demands for high performance and process flexibility from prototype to high-volume production.

Read MoreSolution-based digital composites fabrication

MIT evolves liquid biomaterials into a new approach for sustainable engineered composite structures.

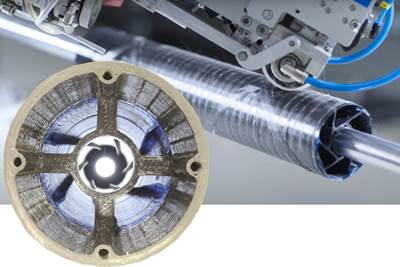

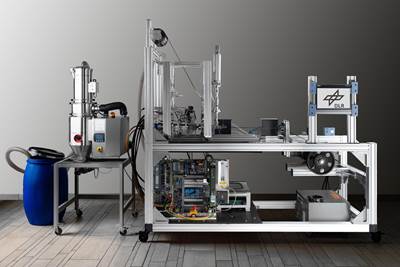

WatchReducing the cost of continuous fiber 3D printing materials

DLR has developed a novel approach to produce thermoplastic impregnated fibers for lower cost versus current slit-tape materials.

Read MoreNorth Carolina State University develops CFRP skin for stealth aircraft

The carbon fiber skin will enable the design of more reliable, durable and efficient stealth jets, offering better electromagnetic conduction and high temperature capabilities.

Read More