Resins

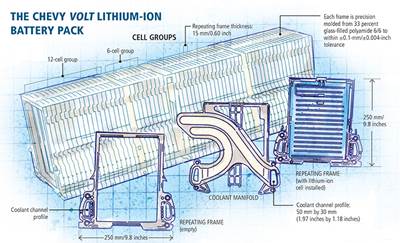

Chevy Volt battery pack: Rugged but precise

GM and partners engineer composites for this complex assembly with an accent on repeatability.

Read MorePaddleboard productivity: Adhesively bonded hull/deck is key

Dragonfly Boatworks LLC's (Vero Beach, Fla.) new standup paddleboard for fly fishing is built without fasteners, with the aid of SG200-40 methacrylate adhesive from SCIGRIP Smarter Adhesive Solutions (Durham, N.C.).

Read MoreDeep draw: Unique laminate architecture enables bus part

For a major mass-transit manufacturer, Amtech LLC (Wapato, Wash.) successfully thermoforms a luggage cover with a remarkably deep draw of 40 inches (1,016 mm), using a laminate architecture that includes a top layer of 0.180-inch/4.5-mm gauge Grade 4800 thermoplastic sheet, supplied by Boltaron (Newcomerstown, Ohio).

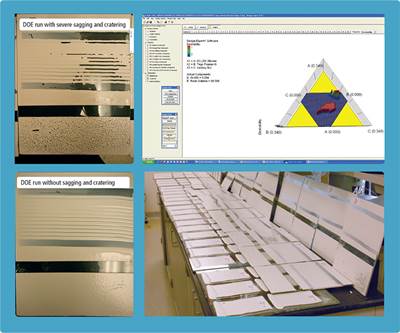

Read MoreCure for cratering: Gel coat perfected with design of experiments software

Resin manufacturer Interplastic Corp. – Thermoset Resins Div. (St. Paul, Minn.), a major gel coat producer, recently developed a new gel coat with the aid of Design-Expert design of experiments software from Stat-Ease Inc. (Minneapolis, Minn.).

Read MoreTenCate's acquisition of Amber Composites a sensible surprise

TenCate, known for years as a thermoplastics specialist, is signaling more and more that it wants to move into new markets with new materials.

Read MoreCured in place pipe: Trenchless trends

A variety of CIPP products are enabling the rehabilitation, rather than excavation and replacement, of underground pipe for wastewater and drinking water.

Read MoreIndustrial corrosion control: Huge opportunities

Fiber-reinforced plastic is the ideal but still widely ignored option in environments that eat away at most metal alloys. Opportunities abound, but the key is still education.

Read MoreTaking the gamble: Betting on material markets

Polystrand builds a new plant to produce market-leading quantities of thermoplastic composite material.

Read MoreExceeding the Limits

Three novel fiber-reinforced, high-temperature thermoplastics promise part designers a broader means to push past performance barriers.

Read MoreHigh-temp thermoplastics: Higher Expectations

As the drive to greater fuel efficiency under the hood catches fire, fiber-reinforced thermoplastics prove they can take the heat.

Read More

.jpg;maxWidth=300;quality=90)