Resins

Aonix Advanced Materials system combines material, machinery

Ottawa-based company develops turnkey technology for high-performance, thermoplastic composites at volumes of up to 1 million parts per month.

Read MoreAFP/ATL evolution

A view of the trends in automated fiber placement and automated tape laying from inside the supply chain.

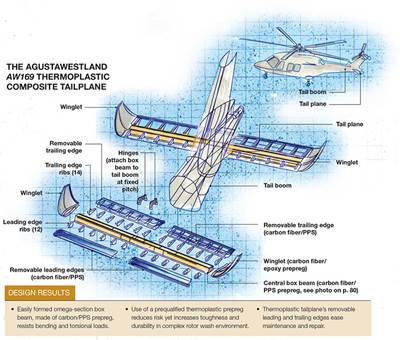

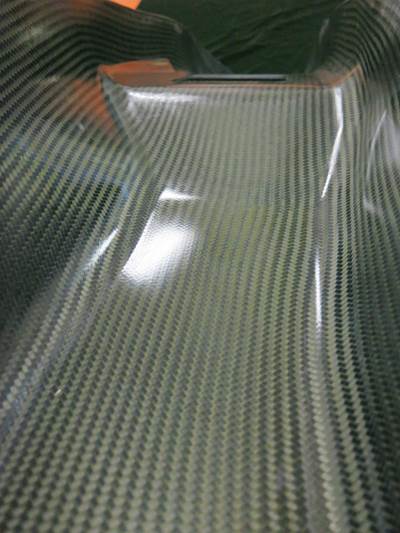

Read MoreThermoplastic composites save weight in rotorcraft aerostructure

This helicopter structure outdoes both metal and thermoset-composite alternatives.

Read MoreNo-oven, No-autoclave (NONA)

Room-temperature cure epoxy composites with a 400°F Tg, comparable properties vs. commercial systems without external heat or post-cure, and offering reduced cost and cycle time. Really?

WatchTwo visions of 3-D printing in CFRP

Freespace Composites and MarkForged pursue different paths to exploit carbon fiber in 3-D printing.

WatchInspection: 30-year-old fiberglass pipeline stands test of time

Examined after three decades in service (half its predicted service life), this filament wound fiberglass pipe showed no signs of degradation.

Read MoreGKN Aerospace funds new aero-engine composites technology

GKN-led G5Demo project will pursue new composites technologies at Linköping-based ACAB subsidiary, aimed to cut aero-engine CO2-emissions in half by 2020.

WatchRenegade Materials demonstrates OOA BMI in wing spar

Renegade Materials Corp. (Miamisburg, Ohio) has developed its RM-3004 out-of-autoclave (OOA) curable bismaleimide (BMI) prepreg for high-performance aerospace applications.

Read MoreBMI and benzoxazine battle for future OOA aerocomposites

Offering weight, cost and process advantages, these “hot zone” resins are moving down the thermometer and into out-of-autoclave structural applications and autoclavable tooling now dominated by epoxies.

Read MoreBenzoxazine: An alternative to phenolic for interior fire safety?

As research into benzoxazine resin chemistry proceeds, this budding high-performance system has the potential to challenge phenolic resins in aircraft interiors.

Read More