Resins

Reducing the cost of continuous fiber 3D printing materials

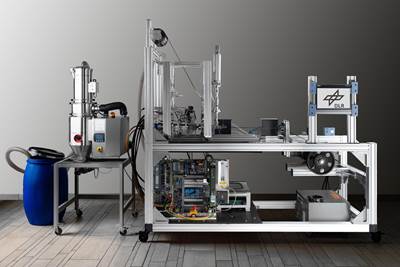

DLR has developed a novel approach to produce thermoplastic impregnated fibers for lower cost versus current slit-tape materials.

Read MoreAdditive manufacturing adds versatility to large marine structures

Dive Technologies and Moi Composites are among those extending composite 3D printing’s design flexibility past prototyping and into customizable end-use parts.

Read MoreQarbon Aerospace launches composite aircraft icing protection system

The thermoplastic composite Helios system will be distributed by AIR Group for use on the leading edges of turboprop aircraft wings and other components.

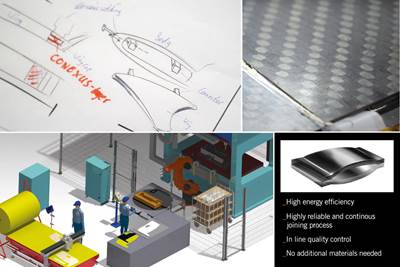

Read MoreCTC GmbH and KTM E-Technologies develop innovative joining technologies for urban air mobility

Partnership develops lightweight approaches including Conexus technology for robotic ultrasonic welding of CFRP laminates.

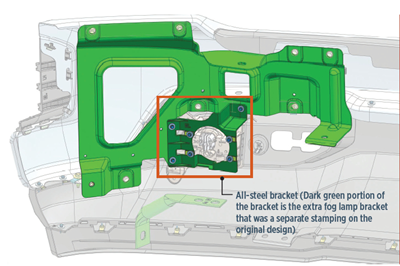

Read MoreThermoplastic composites: Structural bumper bracket

Hybrid bracket reduces mass, increases design flexibility, package space in pickup front bumper.

Read MoreAvient launches moisture-resistant nylon long fiber thermoplastic composite

Nylon 6 and 6/6-based Complēt composite effectively prolongs the effectiveness of a part’s structural capabilities in humid environments and features a smooth surface appearance.

Read MoreMafic USA expects to double U.S. basalt fiber production capacity

Company recently completed its first year of operations in Shelby, North Carolina, and plans for a continued increase in basalt fiber adoption and growth.

Read More9T Labs assesses AM for medical, aerospace applications

9T Labs conducts two studies to assess the viability of its Red Series additive manufacturing system to manufacture a carbon fiber/PEKK aerospace hinge and a surgical tool.

Read MoreOrbital continues to progress toward commercialization

Orbital Composites is pursuing a variety of collaborative projects to apply its Orbital S robotic additive manufacturing system.

Read MoreSTUNNING project successfully develops 8.5-meter thermoplastic fuselage skin

Clean Sky 2 project under the MFFD program produces two segments of an 8.5-meter-long, 4-meter-diameter thermoplastic fuselage skin via NLR’s in-house AFP machine, with consolidation plans this summer.

Watch

.jpg;maxWidth=300;quality=90)