Share

Read Next

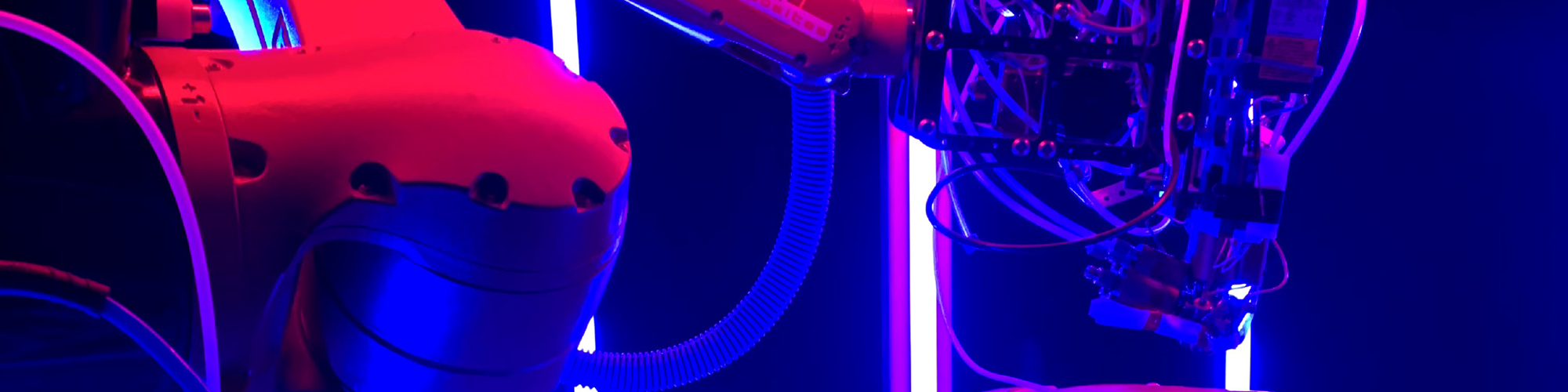

Orbital Composites Orbital S robotic 3D printer. Photo Credit: Orbital Composites

Orbital Composites Inc. (OC, San Jose, Calif., U.S.) reports that it continues to make progress toward commercialization of its Orbital S robotic 3D printing platform. The modular architecture allows a variety of end effectors, additive or subtractive, to produce highly functional multi-material end-use parts. The robotic motion platform allows for printed material to be deposited onto non-planar surfaces. The modularity of the system allows for multiple robots to collaborate within the same workspace.

In 2020, OC announced a collaboration with Oak Ridge National Laboratory (ORNL, Oak Ridge, Tenn., U.S.) to commercialize a robotic 3D printer capable of multi-material deposition of polymers (both thermoplastic and thermosets) and continuous fiber composites for out-of-plane printing. The CRADA project continues at ORNL, with several U.S. Department of Defense and commercial customers already proceeding to purchase systems.

OC shipped its first Orbital S printer to Dr. Gireesh Menta, professor of mechanical engineering at the University of Minnesota, Duluth, who will use it to conduct research on next-generation manufacturing technology. “We are innately passionate about educating the next generation of engineers and advance the research in robotic 3D printing,” says Cole Nielsen, founder and CTO of OC. “We see Orbital S platform as a perfect multidisciplinary teaching and research tool for robotics, 3D printing, advanced materials and software development.”

Orbital Composites Orbital S AM system printing LoreOne shoe. Photo Credit: Orbital Composites

OC also reports that it is focused on identifying and demonstrating use cases for its AM technology for breakthrough end-use parts. Orbital found an amazing partner in Lore (Seattle, Wash., U.S.), a startup developing what is said to be the world’s first 3D-printed hard-shelled road bike shoe. Using scan-to-print carbon technology featuring OC’s Orbital S robotic 3D printing platform, the LoreOne shoe is sculpted with continuous fiber composites to each cyclist’s distinct foot shape. The revolutionary carbon monocoque design creates a more direct connection between rider and bicycle than conventional shoes, producing increased wattage output and pedaling efficiency. Production of the shoe features 12-axis printing, with multiple robots collaborating to create a highly complex continuous fiber layup. This demonstrates mastery in advanced robotics, out-of-plane continuous fiber printing with a zero-degree turn radius and scaled automation.

The two companies are not only aligned in business but have a commitment to sustainability as well. OC says everything from the materials to the manufacturing processes has been chosen to create a zero-waste, closed-loop production system. Lore also plans to establish a return program that encourages customers to return their shoes at end of life so they can be recycled into new shoes.

In the wind energy end market, OC is starting a DOE-funded project to demonstrate large-scale 3D printing of wind turbine blades with continuous fiber at high deposition rates. This project will also demonstrate the concept of a mobile factory, by integrating the robotic printer system within a shipping container that can be easily transported within factories or moved to near-site manufacturing.

Finally, OC has been accepted into the Catalyst Accelerator’s cohort for “On-o]Orbit Servicing, Assembly and Manufacturing.” OC is developing AM tools for electronic composites, enabling on-orbit manufacturing of large, precise and resilient space structures like solar arrays, RF antennas and segmented optics. OC says its on-orbit manufacturing capability will provide increased reliability, reduced cost and accelerated deployment of large space structures, compared to conventional launch systems.

Related Content

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

Orbital Composites to demonstrate containerized 3D printing robots for AM wind blade manufacture

Project aims to demonstrate additive manufacturing of >100-meter-long composite wind blades with >25% reduced cost.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More