RTM

Composites combat ready in UCAVs

As unmanned aircraft are designed from inception for combat duty, composites will carry the payloads in structural components.

Read MoreComposite rib structure for Airbus A380 vertical tail

Fabricator exceeds Airbus performance requirements with hand layed rib truss structure for A380.

Read MoreAdvances in sizings and surface treatments for carbon fibers

As carbon reinforcements find new applications, unfamiliar processes and resin systems make sizing and treatment surprisingly hot topics.

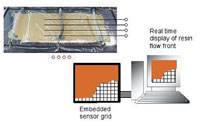

Read MoreAutomated RTM process optimizes cost reduction in VW automotive plant

Efficient production of VW T5 transporter roofs allows ten-year price guarantee.

Read MoreLiquid Composite Molding Achieves Aerospace Quality

Improvements in materials, tooling and process control bring RTM and VARTM into the realm of aerospace components.

Read MoreAirbus A340 carbon composite spoiler made with RTM

When FACC AG (Ried, Austria) contracted to fabricate a demonstration composite replacement part for a highly stressed aluminum spoiler center fitting on the Airbus A340-600, the company wanted to use resin transfer molding (RTM) because the part's complex shape would be difficult to produce consistently and

Read MoreNew Approaches To Cost-effective Tooling

New methods, materials and philosophies add up to tooling innovations.

Read MoreComplex Composites Lighten Nato Copter

Dutch consortium develops advanced composite critical landing gear that meets NH90 helicopter performance requirements.

Read MoreDownhole Composites Boost Durability, Drillability

Halliburton Energy Services, Schlumberger Oilfield Services, Weatherford International, and Baker Oil Tools, all based in Houston, Texas (U.S.A.), offer composite downhole tools — made with both thermoplastics and thermoset resins — for a variety of applications. Halliburton’s FasDrill packers and plugs

Read More