RTM

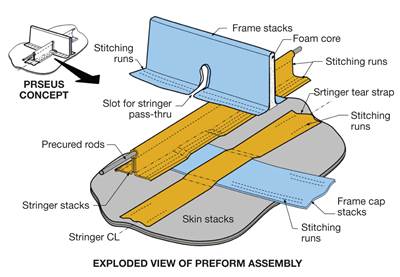

PRSEUS preform for pressurized cabin walls

Over the next few years, NASA and The Boeing Co. (Chicago, Ill.) will build larger and more elaborate pressurized passenger cabin structures for future blended-wing airliners.

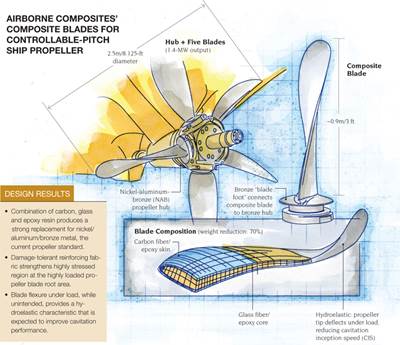

Read MoreComposite propeller for Royal Navy minehunter

Composite-for-metal replacement brings multiple benefits.

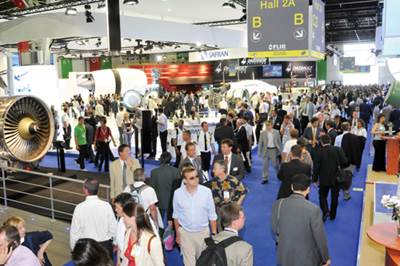

Read More2011 International Paris Air Show

At the 49th event, records are set for attendance and aircraft orders, and airframers go on record about composites-related developments.

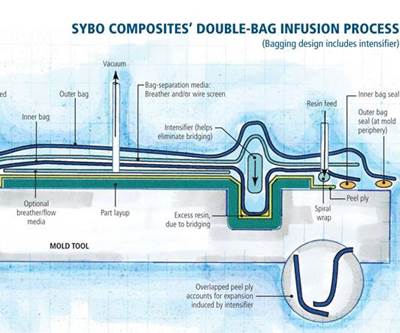

Read MoreDouble-bag infusion: 70% fiber volume?

A double vacuum-bag system and tight process control enable repeatable fiber volumes of 60 to 70 percent and improves consistency of infused laminates.

Read MoreMold heating study proves pressurized water system

Westminster Solutions and SINGLE Temperature Controls partner to create an RTM cell that heats the mold more efficiently with pressurized water rather than with a conventional oil heating system..

Read MoreSQRTM enables net-shape parts

New out-of-autoclave process combines resin transfer molding with prepregs for complex helicopter part prototype.

Read MoreStructural armor or armored structures?

Either way, antiballistics engineers seek structural integrity and ballistic deterrence from a single design.

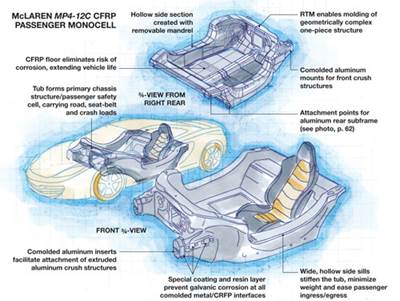

Read MoreF1-inspired MonoCell: Racing safety for the road

Resin transfer molding makes CFRP passenger cell mass-producible for new model supercar.

Read MoreDigital design, RTM update aircraft propeller

Second-generation type-certified propeller delivers for Cirrus Aircraft’s SR-22 at a more affordable price.

Read More

.jpg;maxWidth=300;quality=90)