Thermoplastics

ORNL demonstrates 3-D printing with carbon fiber

Oak Ridge National Laboratory can print carbon fiber reinforced parts from 10 cm in size up to 2.4m in both lab and production settings at its Carbon Fiber Technology Facility.

Read MoreMolding i3 body panels

Beyond its CFRP Life Module, BMW's i3 commuter car features doors, door inners, fenders, bumpers, a hood and a rear spoiler made from injection molded thermoplastic.

Read MoreMove over honeycomb, thermoplastic sandwich is commercialized as DYNATECH

PEI foam core/skin sandwich panels claim to save up to 40 percent weight and 30 percent cost in rail and aircraft interiors vs. honeycomb.

Read MoreLicense to speed for composites manufacturing

RocTool pushes composites into new markets with its high-speed induction heating technology for molding.

Read MoreComposites for heavy truck: Tough-duty inspection cover

Thermoplastic composite reduces weight, cost, corrosion, extends maintenance intervals.

Read MoreHighlights: JEC Europe 2014

Composites enable high performance and lower weight in washtubs, wheelchairs and engine exhaust cones. Plus new, ultralight materials.

Read MoreAonix Advanced Materials system combines material, machinery

Ottawa-based company develops turnkey technology for high-performance, thermoplastic composites at volumes of up to 1 million parts per month.

Read MoreAFP/ATL evolution

A view of the trends in automated fiber placement and automated tape laying from inside the supply chain.

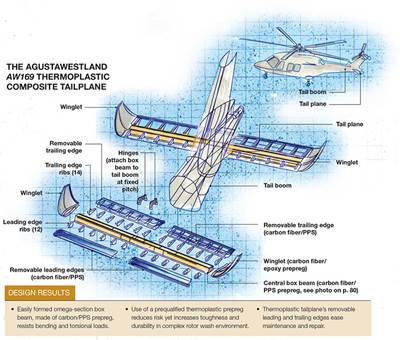

Read MoreThermoplastic composites save weight in rotorcraft aerostructure

This helicopter structure outdoes both metal and thermoset-composite alternatives.

Read MoreTwo visions of 3-D printing in CFRP

Freespace Composites and MarkForged pursue different paths to exploit carbon fiber in 3-D printing.

Watch