Thermoplastics

Inside a thermoplastic composites hotbed

As production of the A350 XWB ramps up, so does manufacture of the thermoplastic fuselage clips the plane requires. HPC sees how it’s done.

Read MoreWind blades: Progress and challenges

Despite double-digit wind energy industry growth, turbine blade manufacturers and materials suppliers acknowledge a pressing need to reduce costs and innovate.

Read MoreAdditives and modifiers: Matrix optimization

New and reengineered modifiers for thermosets and thermoplastics target previously elusive goals in composites processing and performance.

Read MoreMarket outlook: Fiber-reinforced phenolics

Phenolics gain new footholds in anticorrosion markets now dominated by polyesters and epoxies.

Read MorePultruding polyurethane: Sheet pilings break boundaries

High-pressure pultrusion process creates polyurethane composite sheet pile system with the strength and stiffness to compete with steel.

Read MoreEvolution of tailored D-LFT

In the past two decades, two competing composite technologies — sheet-form glass-mat thermoplastic (GMT) and pelletized long-fiber thermoplastic (LFT) — led to the development of a new form of glass-reinforced thermoplastic composite.

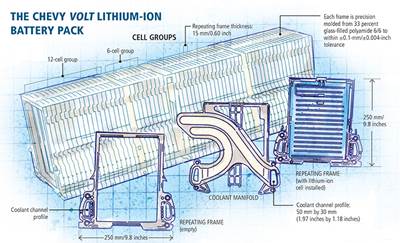

Read MoreChevy Volt battery pack: Rugged but precise

GM and partners engineer composites for this complex assembly with an accent on repeatability.

Read MorePaddleboard productivity: Adhesively bonded hull/deck is key

Dragonfly Boatworks LLC's (Vero Beach, Fla.) new standup paddleboard for fly fishing is built without fasteners, with the aid of SG200-40 methacrylate adhesive from SCIGRIP Smarter Adhesive Solutions (Durham, N.C.).

Read MoreDeep draw: Unique laminate architecture enables bus part

For a major mass-transit manufacturer, Amtech LLC (Wapato, Wash.) successfully thermoforms a luggage cover with a remarkably deep draw of 40 inches (1,016 mm), using a laminate architecture that includes a top layer of 0.180-inch/4.5-mm gauge Grade 4800 thermoplastic sheet, supplied by Boltaron (Newcomerstown, Ohio).

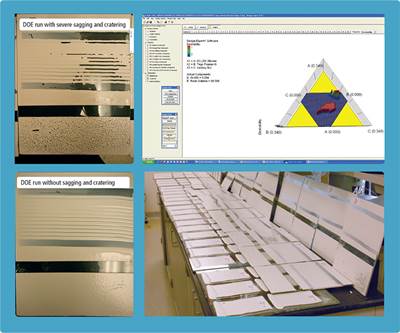

Read MoreCure for cratering: Gel coat perfected with design of experiments software

Resin manufacturer Interplastic Corp. – Thermoset Resins Div. (St. Paul, Minn.), a major gel coat producer, recently developed a new gel coat with the aid of Design-Expert design of experiments software from Stat-Ease Inc. (Minneapolis, Minn.).

Read More