Company R&D supports specialty resins, additives development

CAMX 2024: Interplastic highlights its range of specialty resin offerings, as well as its advancements in R&D producing gelcoats, colorants, bonding compounds, adhesives and putties.

Share

Interplastic Corp. (Covington, Ky., U.S.), a U.S.-owned and operated company offering a collective experience of 500 years, specializes in unsaturated polyester, vinyl ester and specialty resins. The company also produces gelcoats, colorants, bonding compounds, adhesives and putties under CoRezyn and Silmar brand names for the composites, cast polymer and solid surface industries. Its CoRezyn vinyl esters are said to be reliable for high-performance and high-corrosion applications, designed to be used across marine, transportation and construction industries. Silmar, its flagship brand for low-color (clear) resins, optimizes quality and consistency. As part of the IP Corp. family of companies, Interplastic partners with HK Research for other robust gelcoat manufacturing options.

The company has also expanded its manufacturing capabilities and invested in R&D. All of Interplastic’s manufacturing facilities and research labs maintain ISO 9001:2015 certification from ABS Quality Evaluations Inc., ensuring rigorous quality management practices and product refinement. The company also highlights its commitment to environmental responsibility, which is reflected in its ISO 14001:2015 registered environmental management systems.

Interplastic’s sales team is available to address inquiries and provide technical expertise.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreRead Next

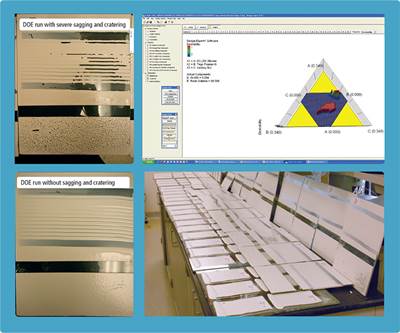

Cure for cratering: Gel coat perfected with design of experiments software

Resin manufacturer Interplastic Corp. – Thermoset Resins Div. (St. Paul, Minn.), a major gel coat producer, recently developed a new gel coat with the aid of Design-Expert design of experiments software from Stat-Ease Inc. (Minneapolis, Minn.).

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More