Composite tooling specialist displays compression mold capabilities

CAMX 2024: Century Tool specializes in the in-house design, build and run-off of dimensionally large parts and Class A surface tooling.

Share

Century Tool (Fenton, Mich., U.S.), a Tooling Tech Group company and a composites tooling specialist, is highlighting its expertise in compression molds for composites. Century Tool provides design, build and run-off of tooling with a specialization in dimensionally large parts and Class A surface tooling for the automotive, aerospace, heavy truck, powersports and bath industries. The company provides molds for high-profile vehicles such as the Corvette, Jeep and Ford Bronco.

All Century Tool molds and tools are designed, engineered and manufactured in-house based on customer-supplied part data. Key to the effectiveness of the company’s tooling solutions is its high-speed precision machining capability with bed sizes of up to 343" long × 100" deep × 120" tall and the ability to machine molds of 100,000+ lbs. Additionally, the company maintains presses from 1,000-3,000 tons for both low-volume production and die tryout.

Century Tool says it can help companies achieve their lightweighting strategies by providing tooling capable of producing complex, aerodynamic shapes. As a vertically integrated company providing everything from design through try-out, tight control is maintained over quality to provide custom services to meet total program needs.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreRead Next

Corebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.

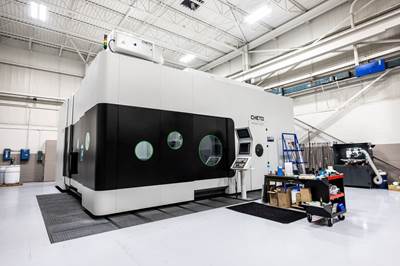

Read MoreCentury Tool investment boosts efficiency, capability in tooling for composites

Designer and builder of compression molds for composite structures installs seven-axis CNC deep-hole drilling and milling machine to improve productivity.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More