Comprehensive service formulates standard, custom SMCs

CAMX 2024: As an SMC product manufacturer, Molding Products LLC provides SMC formulations and technical support for diverse markets, from R&D to post-production.

Share

Molding Products LLC (South Bend, Ind., U.S.) specializes in engineered sheet molding compound (SMC) products. The company’s state-of-the-art Technology Center is equipped to handle the entire lifecycle of product development. Intending to optimize SMC and tooling designs for precision and efficiency, Mold Products designs, develops and scales up with R&D SMC machinery and several prototype large pattern presses.

Molding Products’ expertise spans transportation, infrastructure, construction, automotive, agricultural, HVAC, heavy-duty trucks and more sectors. While it is not directly involved in custom molding, it has expanded its operations through key alliance, enabling the company to offer customers comprehensive solutions from initial concept to final product.

It provides custom and standard SMC formulations tailored to customers’ specific needs, with aid from the company’s technical support team. Molding Products aims to demonstrate how its SMC products and solutions can elevate its collaborators’ businesses — whether for high-strength structural applications, low-density lightweight parts or adherence to stringent Class A automotive standards.

Related Content

-

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

-

IDI Composites opens new global headquarters, manufacturing and technology center

The Noblesville, Indiana, facility includes SMC and BMC manufacturing, an R&D center and the company’s corporate headquarters.

-

SMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Related Content

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

Read MoreIDI Composites opens new global headquarters, manufacturing and technology center

The Noblesville, Indiana, facility includes SMC and BMC manufacturing, an R&D center and the company’s corporate headquarters.

Read MoreSMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

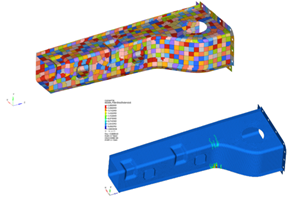

Read MoreSMC simulation tool enhances design optimization

CAMX 2023: FiRMA, Engenuity’s new approach to SMC, uses a predictive technique that accurately reflects material properties and determine the performance range an SMC part or structure will exhibit.

Read MoreRead Next

SMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read MoreDesigning a carbon fiber SMC brake lever

Germany-based Blackwave GmbH’s bicycle brake lever saves 35% of the weight for a comparable aluminum part.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More