Controlled polymer ablation technology seeks to redefine surface prep

CAMX 2024: Plasma Bound’s CPA technology, powered by quality control system Vulcan, applies atmospheric pressure plasma to achieve high-level composite bonding.

Share

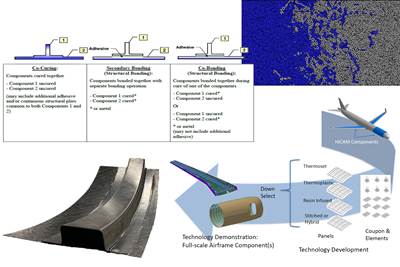

Figure 1: Controlled polymer ablation (CPA) process in application. It can be single or multiple heads. Source (All Images) | Plasma Bound

Plasma Bound (Dublin, Ireland), an Irish deep-tech company, excels in high-performance surface preparation for the bonding of composite assemblies across various industries. Its novel solution, controlled polymer ablation (CPA), tackles bonding difficulties for lightweight materials, such as carbon- and glass fiber-reinforced polymers. By using an atmospheric pressure plasma, CPA removes surface polymer, resulting in a highly energized surface with an enhanced surface area ready for bonding or coating.

Figure 2. Plasma Bound’s Vulcan control module, currently used to deploy the CPA process at the line.

The company’s CPA technology is underpinned by commercial atmospheric plasma equipment and is currently deployed using Plasma Bound’s quality assurance and control product, Vulcan (Fig. 2). Vulcan enables in-situ quality validation and process-level control of surfaces for adhesion applications, providing quality assurance records of process and parts on a batch and/or part basis.

Figure 3. Three “milestone” levels of CPA treatment on lightweight composites as viewed by the human eye. Inserts are scanning electron micrographs of the surface.

One of CPA’s stand-out features, is its precise control over the depth of polymer removal from the surface. Fig. 3 illustrates three progressive stages of removal from a carbon fiber composite — untreated, skimmed, partially and fully revealed fibers. The ability to target anywhere along the spectrum of these gradients enables different bonding strategies for different end-uses.

According to Plasma Bound, its CPA technology, powered by Vulcan, has been validated in the automotive sector and offers multiple benefits in various sectors, including:

- Automation: Facilitates faster assembly times and improved bond strengths.

- Lightweighting: Enables automakers to reduce vehicle weight without compromising safety, meeting stringent emissions regulations.

- Sustainability: Minimizes material waste, scrap production and energy consumption, aligning with circular economy principles.

- Fuel efficiency: Enhances fuel efficiency, critical for airlines and space exploration, by expanding the availability of lightweight structures.

- Reduced waste: Replaces wasteful peel-ply and abrasion processes, cutting down on scrap and rework efforts.

- Energy efficiency: Reduces energy consumption through a low-energy input process, eliminating unnecessary process steps, and removing consumables.

- Safer materials: Offers reliability and stronger lightweight structure along with reduced non-compliances.

Plasma Bound’s ambition is to deploy its CPA platform technology globally, to enable manufacturers to improve quality and safety, increase efficiency and reduce cost.

Related Content

-

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

-

CAMX announces general session presenter, open registration

Attendees registered for the Oct. 31 – Nov. 2, 2023 event in Atlanta, Georgia, are invited to attend this year’s keynote put on by Joan Higginbotham, a former NASA astronaut and president of aerospace consulting firm Joan Higginbotham Ad Astra LLC.

-

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Related Content

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

Read MoreCAMX announces general session presenter, open registration

Attendees registered for the Oct. 31 – Nov. 2, 2023 event in Atlanta, Georgia, are invited to attend this year’s keynote put on by Joan Higginbotham, a former NASA astronaut and president of aerospace consulting firm Joan Higginbotham Ad Astra LLC.

Read MoreVIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Read MoreRecycled carbon veil designed to close carbon fiber lifecycle loop

CAMX 2023: Technical Fibre Products’ new nonwoven veil can be reused in composites, effectively closing the loop and providing a viable route for the recycling of fibers.

Read MoreRead Next

Plasma treatment as surface preparation for adhesive bonding

Concurrent with the TRUST program's development of process control, it is addressing the need for more robust surface prep. methods.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More