Polymer systems facilitate architectural, structural repair and protection

CAMX 2024: ChemCo Systems’ products are designed to install, protect or repair concrete, steel, wood as well as composite systems.

Share

ChemCo Systems (North Fair Oaks, Calif., U.S.), a division of American Polymers Corp., manufactures a diverse selection of highly durable polymer systems for use in civil infrastructure and construction repair applications.

Founded in 1993 by the same experienced technical staff who developed the SCB system of structural crack repair at Adhesive Engineering, ChemCo’s products are designed to install, protect and repair architectural and structural concrete, as well as bond and protect substrates including steel, wood, and carbon and glass fiber composite systems.

ChemCo Systems’ products are available for: structural crack repair, anchor bolts, coatings and sealants for corrosives, machine bases, old-to-new pours, joint nosing, control joint filling, seismic upgrades, plate bonding reinforcement, spall and void repair, underwater (marine) and extreme environments including coatings that can protect against concentrated sulfuric acid spills.

ChemCo Systems offers an experienced technical service and R&D team to provide customers with quick responses and the ability to customize products for difficult applications. The company’s in-house testing lab is well equipped to handle most AASHTO, ACI, ASTM, CSI, DOT, ICRI and International standards. Recent innovations include:

- InsulPOX for protecting plant environments, reducing explosion and cold cloud hazards from spills of cryogenic liquids including LNG, H², O², N², Ar, He and the new clean fuel, green H²

- Acrylic, polyurea and epoxy line striping for pavements

- High friction surface treatment (HFST) epoxies for highways

- Street demarcation technologies using colored recycled glass for smart cities

- Ambient temperature EA (1:1) tack coat and repair binder.

ChemCo Systems’ product lines are manufactured in strategic locations across the U.S., including the states of California and Texas, and Chicago and Atlanta. Substantial inventory of raw materials and finished goods are maintained to serve contractor needs quickly, particularly during unpredictable shortages.

Related Content

-

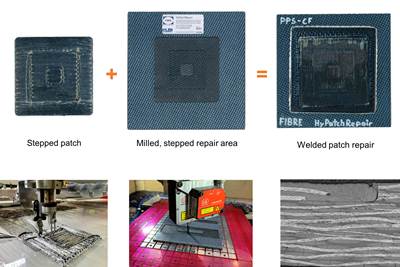

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

-

Aerodynamic considerations when repairing complex composite structures

An example process gives steps and issues to consider when determining the most effective repair method for preserving the aerodynamic surface of a complex-contoured composite sandwich structure.

-

Toray jointly wins Infrastructure Maintenance award for steel pipe repair innovation

Together with Tokyo Electric Power Grid and Yasuda Seisakusho, Toray employed in-situ VARTM with carbon fiber sheets to repair steel pipe corrosion on transmission towers, with application extension underway.

Related Content

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreAerodynamic considerations when repairing complex composite structures

An example process gives steps and issues to consider when determining the most effective repair method for preserving the aerodynamic surface of a complex-contoured composite sandwich structure.

Read MoreToray jointly wins Infrastructure Maintenance award for steel pipe repair innovation

Together with Tokyo Electric Power Grid and Yasuda Seisakusho, Toray employed in-situ VARTM with carbon fiber sheets to repair steel pipe corrosion on transmission towers, with application extension underway.

Read MoreCompPair adapts HealTech composites to LCM processes

The new system, demonstrated through the manufacture of a large-scale wind turbine blade section, enables the repair and recovery of infused composite structures within minutes.

Read MoreRead Next

Composites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More