Precision universal testers optimize materials testing, analysis

CAMX 2024: Fast and flexible AGX-V2 Series by Shimadzu provides more intelligent operability for testing tasks, supporting composites, plastics, metals and finished products.

Share

Shimadzu Scientific Instruments (Columbia, Md., U.S.) offers a wide range of high-quality instruments for fast, reliable composites testing. A key part of this portfolio is the AGX-V2 Series. Available in a range of sizes, these universal testing systems feature control technology that ensures optimal functionality and high-speed data sampling — enabling the detection of sudden changes in samples during testing — and reduced maintenance tasks. The systems require a single load cell to operate, to save time on calibration and spend less money on load cell replacements.

The AGX-V2 is available in tabletop models with frame capacity up to 50 kN (11,000 lbf) and floor models with frame capacity up to 600 kN (135,000 lbf). Ultra high-speed (10 kHz) data sampling and crosshead control (1kHz) enable precise stress and strain control, while a modular control unit allows expansion of data acquisition inputs (20 max), sensor outputs (20 max) and digital control outputs.

An intelligent crosshead enhances operability and adds additional safety precautions to protect hardware and users. The AGX-V2’s multi-joint feature also connects the jigs to load cells. It enables all jigs — including tensile, compression and bending jigs — to be quickly and easily connected. This means that it’s longer necessary to replace heavy joints, which simplifies the replacement of test jigs. A small-capacity load cell can be connected directly to the tip, so tests with small-capacity load cells can be performed with a large-capacity load cell still attached.

Moreover, the series’ use of Trapezium X-V software provides a user-friendly interface that enables fast and simple analysis, particularly when performing single-direction tests, such as tensile, compression and bending tests. The software can also run endurance tests that involve the repeated application of force. The software system’s versatility supports the analysis of many materials types, including composites, plastics, metals and finished products.

A precision alignment system and software allow users to achieve Class 10 alignment or better. A wide range of jigs and other accessories enable combined loading compression, mixed mode bending, open hole compression and shear testing, among others.

Related Content

-

Recycled carbon veil designed to close carbon fiber lifecycle loop

CAMX 2023: Technical Fibre Products’ new nonwoven veil can be reused in composites, effectively closing the loop and providing a viable route for the recycling of fibers.

-

High-strength, nondestructive adhesive-bonded fasteners

CAMX 2023: Rotaloc bonding fasteners come in a variety of baseplate styles, threads, sizes and materials for high-strength, nondestructive bonding with fiber-reinforced composites and thermoset/thermoformed plastics.

-

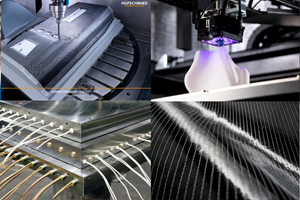

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Related Content

Recycled carbon veil designed to close carbon fiber lifecycle loop

CAMX 2023: Technical Fibre Products’ new nonwoven veil can be reused in composites, effectively closing the loop and providing a viable route for the recycling of fibers.

Read MoreHigh-strength, nondestructive adhesive-bonded fasteners

CAMX 2023: Rotaloc bonding fasteners come in a variety of baseplate styles, threads, sizes and materials for high-strength, nondestructive bonding with fiber-reinforced composites and thermoset/thermoformed plastics.

Read MoreVIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Read MoreCAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

Read MoreRead Next

Shimadzu XSeeker 8000 is designed for simplicity

The new user-friendly XSeeker 8000 benchtop X-ray CT system enables high functionality with a small footprint.

Read MoreMachine, equipment investment strengthens Ruckus Composites’ research, innovation

CNC services expansion, universal testing machines and advanced inspection enable Ruckus to delve deeper into the study and evaluation of carbon fiber damage, as well as nondestructive and destructive testing.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More