Standard, specialized fasteners provide complete composite component solutions

CAMX 2024: Perlane Engineered Fastening Systems Division of Component Solutions Group works closely with engineering teams from initial design phase to prototyping and testing to meet a variety of project fastener needs.

Share

The Perlane Engineered Fastening Systems Division of Component Solutions Group (CSG, Dayton, Ohio, U.S.), backed by a team of seasoned experts, specializes in the design and development of high-performance fasteners for composite materials. “We want engineering teams to understand that we are a complete component solution,” says sales engineer and business development representative Chris Seidell. “We’re working side by side with engineers across all industries.”

From the initial design phase to prototyping and testing, CGS works closely with engineering teams across various industries to ensure high quality and performance. Each joint can be customized for the specific project and its distinctive requirements, which could involve multiple vendors to make each part. This would include specially designed blind fasteners and compression limiters to address the challenges of working with a variety of composite materials. CGS notes that its solutions are especially effective when having to attach components to fiberglass and other plastics.

For instance, CSG offers many solutions for applications where strength and corrosion resistance are essential. A recent aerospace challenge involved connecting a windscreen to a composite structure on a military heavy-lift helicopter. The base of the graphite/carbon fiber epoxy composite structure varies in thickness from 0.125-0.500". The customer needed a fastener that was strong enough to hold on the windscreen, resist corrosion and prevent rotation built into the part. The solution developed was the “Teardrop” rivet nut fastener, a stainless steel, thread-locked, dry film-lubricated, special head configuration rivet nut.

“One issue that became apparent was that composites manufacturers couldn’t use hex holes, which is the best practice for rivet nuts to prevent spin-out. Since composite material cannot be punched the way that sheet metal can be, it was imperative that the CSG team came up with a part that met the torque requirements but didn’t damage the mating material while still being corrosion-resistant.”

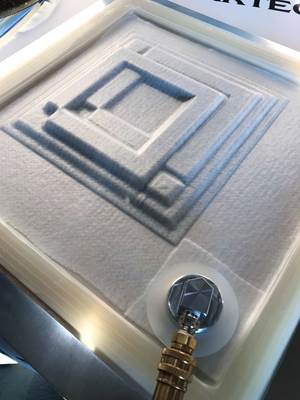

Another solution developed to address these issues is the Optisert round body rivet nut. This specialized part features aggressive wedges under the head, which press into the parent material to increase resistance to spin-out. This enhancement provides a stronger thread in softer materials like plastic, fiberglass and aluminum.

The company has also worked with several OEMs on attaching components to rotomolded plastic materials (notorious for having very wide tolerances) or for applications that require the use of compression limiters, which can be customized and manufactured according to the customer’s specifications.

Models of some of CGS’ recent design solutions can be viewed at its booth.

Related Content

-

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

-

Cutting supplies, equipment enhance composites testing in the lab

CAMX 2024: On display at Extec’s booth is the Labcut 5000 precision composite plate saw, Nikon MA200 inverted metallurgical microscope and Labpol 12 automatic grinder/polisher.

-

Reusable vacuum bagging solutions for composite applications

CAMX 2023: Smartech underscores its industrial reusable vacuum bagging products for reduced waste, easy debulking and the capability to be used for complex projects.

Related Content

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read MoreCutting supplies, equipment enhance composites testing in the lab

CAMX 2024: On display at Extec’s booth is the Labcut 5000 precision composite plate saw, Nikon MA200 inverted metallurgical microscope and Labpol 12 automatic grinder/polisher.

Read MoreReusable vacuum bagging solutions for composite applications

CAMX 2023: Smartech underscores its industrial reusable vacuum bagging products for reduced waste, easy debulking and the capability to be used for complex projects.

Read MoreGraphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

Read MoreRead Next

FiberJoints innovates composite bolted joints for reduced weight, cost and maintenance

Novel reinforcing patch uses braided sleeve to boost the load-carrying capacity of composite bolted joints.

Read MoreFastener selection for composite materials

How to navigate terminology, materials and functionality in choosing the right fastener for components or assemblies involving composite materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More