VIDEO: Painting parts with self-learning robots

LestaUSA’s self-learning robots on display at CAMX 2024 enhance composites manufacturing workflow and workforce needs.

Share

Scott Francis, editor-in-chief of CompositesWorld, spoke with Derek DeGeest, president at LestaUSA (Tea, S.D., U.S.), at CAMX 2024.

Lesta showcased the company’s partnership with Magnum Venus Products (MVP, Knoxville, Tenn., U.S.) to bring self-learning robotic solutions to the composites industry.

These robots, which have been used in the metals and wood industries for more than two decades, offer automation to address labor shortages.

They are versatile, capable of handling both small- and large-scale applications, including chop and gelcoat spraying.

The robots enable real-time programming and can be used with existing staff, creating career opportunities. They also offer offline programming and optimization options, making them scalable for various composites manufacturing needs.

Related Content

-

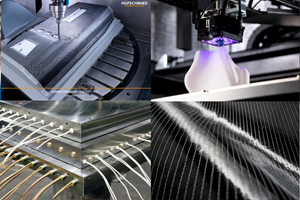

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

-

Concentrated smooth dispersion simplifies electrical conductivity applications

CAMX 2024: Total Resin presents Total Nanotüp, a concentrated dispersion of carbon nanotubes in a bifunctional reactive monomer for polyester, vinyl ester, melamine and acrylic resins.

-

High-strength, nondestructive adhesive-bonded fasteners

CAMX 2023: Rotaloc bonding fasteners come in a variety of baseplate styles, threads, sizes and materials for high-strength, nondestructive bonding with fiber-reinforced composites and thermoset/thermoformed plastics.

Related Content

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read MoreConcentrated smooth dispersion simplifies electrical conductivity applications

CAMX 2024: Total Resin presents Total Nanotüp, a concentrated dispersion of carbon nanotubes in a bifunctional reactive monomer for polyester, vinyl ester, melamine and acrylic resins.

Read MoreHigh-strength, nondestructive adhesive-bonded fasteners

CAMX 2023: Rotaloc bonding fasteners come in a variety of baseplate styles, threads, sizes and materials for high-strength, nondestructive bonding with fiber-reinforced composites and thermoset/thermoformed plastics.

Read MoreCAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

Read MoreRead Next

MVP partners with LestaUSA to bring robotics to composites

Self-learning robotic solutions are designed to simplify the automation process for composites manufacturers of all sizes wanting to incorporate automated spray applications.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More