2010 SAMPE Europe/JEC Paris Showcase

Record crowds and reignited technological development testified to the composite industry’s renewed health and the recent recession’s demise.

Colocated again in Porte de Versailles, Paris, France, the SAMPE Europe Conference and the JEC Composites Show expressed a much more buoyant mood than the cautious optimism of last year’s events. The 31st SAMPE Europe International Conference (SEICO 10) took place at Hotel Mercure Paris Porte de Versailles Expo from April 12-14.

The conference keynote address by Dr. Leslie Cohen (HITCO Carbon Composites, Gardena, Calif.) explored his company’s “Transformation to Automation, the Journey and the Technology for Aerostructures” and the overwhelmingly positive effects that transformation has had on product affordability and performance. Dr. Cohen’s talk was an exhortation to the industry to anticipate and welcome the future by preparing for changing business conditions. (An excerpt from his address is presented in “Speaking Out,” this issue. Click on "The digital thread: Transformatin to automation," under Editor's Picks").

A highlight of the nearly 100 technical paper presentations in 11 subject areas were the five subsessions devoted to an overview of and a midcourse update on the Advanced Low-Cost Aircraft Structures (ALCAS) program. The €101 million ($140 million USD), six-year project, nearing its January 2011 end date, is headed by Airbus (Toulouse, France) in cooperation with 60 other aerospace firms representing Europe and the Middle East. Conference attendees got an update on progress toward the program goal: reducing the operating cost of European commercial and business aircraft by 15 percent through the application of carbon fiber composites in wing and fuselage structures.

At the nearby Paris Expo, the 2010 JEC Composites Show (April 13-15) was an encouraging change from the 2009 show, which, held at the low point of the global recession, was only moderately attended. In sharp contrast, the 2010 event tallied a record 27,500 visitors and exhibitor personnel, with a more than 30 percent increase in attendance from outside France. Moreover, the level of new investment, new product introductions and technical innovations in evidence on the show floor indicated that the composites industry is headed for economic health.

HPC editor-in-chief Jeff Sloan and technical editor Sara Black were on hand at the Expo. The following is a representative sample of the many newsworthy developments.

_________________________________________________

Glass fiber for European markets

AGY Holding Corp. (Aiken, S.C.) is expanding its global manufacturing footprint by integrating products made at its Chinese manufacturing operation (acquired in 2009) with those produced at its U.S. operation. With the high-tensile glass fiber yarn now spun in Shanghai, China, AGY has entered the European construction and industrial markets, in which it previously declined to participate due to high duties on imported U.S. yarns. In addition, the Chinese plant now makes small-denier yarn for Asian-made circuit boards. At the U.S. plant, the company has introduced an ultrafine yarn, BC 3000, which contains just 50 filaments of 4-micron diameter glass fiber. Converted in Japan, the ultrafine fabric is laminated with epoxy resin to produce very thin printed circuit boards for ever-smaller electronics, and it is used in Apple’s iPhone, says the company.

_________________________________________________

Resin removal scrapers for tooling

Distributor AeroConsultants AG (Nänikon-Uster, Switzerland) showed a new family of inexpensive yet highly useful handheld mold scrapers, manufactured by Elixair International Ltd. (Dorchester, Dorset, U.K.). Made from various thermoplastic resins, including polyetheretherketone (PEEK), SkyScrapers remove cured composite resins from composite molds without surface scratching and are also targeted to both production and maintenance, repair and overhaul (MRO) organizations, where composite repair resins are removed. The scrapers can be resharpened multiple times using a small supplied sharpener (the Skymill). Other shapes suitable for spreading adhesives (SkyBlade, SkySpreader, SkyGrip) are also available. SkyScrapers are approved by both Boeing and Airbus for MRO activities.

________________________________________________

High-temp benzoxazine tooling prepreg

Airtech International Inc. (Huntington Beach, Calif.) debuted Beta Prepreg, a tooling prepreg material that uses benzoxazine resin chemistry developed by Henkel Corp. (Rocky Hill, Conn.). Reportedly, the prepreg remains stable for a minimum of six months at room temperature and features low resin shrinkage during cure and low moisture absorption. The use of benzoxazine in place of an epoxy matrix also gives the prepreg a very high glass transition temperature and increases its toughness and machinability. The cured material is said to be conducive to complex geometric detail — especially useful when tool surfaces must be modified.

Also new: Toolfusion 3 is a nano-particle-enhanced resin infusion system for the manufacture of high-temperature, out-of-autoclave tooling laminates. Dahltexx SP-2 is a semipermeable membrane for use as tool-side or bag-side breathers to help remove air and liquid resins. Econostitch G is a polyester peel ply for use with polyesters and epoxies. WL3900 R/B is a high-elongation release film for use with polyester, vinyl ester and epoxy. It functions in temperatures up to 157°C/315°F and is designed for compaction and debulking operations. Airdraw 2 is a vacuum bagging film that features an embossed pattern and stiff formulation. It allows users to avoid using breather fabric during debulking.

_________________________________________________________________________

Hardeners/accelerators for epoxy resins

Chemical supplier AlzChem AG (Trostberg, Germany) showed its range of trademarked DYHARD resin hardeners and latent/nonlatent accelerators for epoxy resins. With a company history dating back to 1908, AlzChem was part of Degussa AG prior to 2006.

_________________________________________________________________________

Carbon nanotube concentrates for epoxies

Graphistrength CS1-25 from Arkema Inc.(Cedex, France) is a new solid concentrate of carbon fiber nanotubes (25 percent by weight) that is designed to be fully dispersed in liquid epoxy resin. Carbon fiber nanotubes (CNTs) are typically available in compounded resin systems, usually in concentrations of 1 to 4 percent. Arkema’s concentrate formulation is designed to allow processors the flexibility to change and adjust CNT loadings. Similarly, Graphistrength CM12-30 is a CNT masterbatch developed for thermoplastic polymer matrices.

_________________________________________________________________________

ATL for carbon/PEEK composites

Automated Dynamics (Schenectady, N.Y.), with new management and personnel in place, showed its capabilities in both innovative composites processing equipment for fiber placement and automated tape laying as well as composite parts and structures for oil field and aerospace applications. According to the company, its machines can produce parts from high-performance materials, such as carbon fiber/polyetheretherketone (PEEK), in a wide variety of shapes and sizes, including complex geometries up to 40 ft/12.3m long.

_________________________________________________________________________

Industrial 3-D weaving machine

BITEAM AB (Bromma, Sweden), together with the Royal Institute of Technology (KTH, Stockholm, Sweden), announced the development of the first industrial 3-D weaving machine for producing three-dimensional profiles. The company also was involved in the EU Project MOJO (MOdular JOints for Aircraft Composite Structures) with Dassault Aviation (Paris, France), Eurocopter (Marignane, France), Premium Aerotec (Augsburg, Germany) and others, which produced the winning component in the JEC Innovation Awards “Process” category. The MOJO project sought new methods for substantially lowering fabrication costs and weight of aircraft. Biteam woven profiles helped the MOJO partners to reach that goal by enabling aircraft part joinery without metallic fasteners. The company also introduced its new flapped triangular cross-section preform insert for the strengthening of junctions to help suppress crack propagation and delamination. It features integrated flaps at the three edges of the triangular insert, which can be directly integrated with the surrounding sheet materials.

_________________________________________________________________________

Carbon fiber source ramps up

Bluestar Fibres Co. Ltd. (Grimsby, U.K.) showcased its growing carbon fiber manufacturing capacity and customer base. It recently increased its precursor capacity in the U.K. to 22,000 metric tonnes (48.51 million lb) per year, producing tow sizes from 3K to 400K. It also will begin precursor production in China in 2011 at the rate of 5,000 metric tonnes (11.02 million lb) per year. A new carbon fiber facility in Lanzhou, China is starting up this year and will produce 1,600 metric tonnes (3.52 million lb) of Starafil fiber on one line, and a second line is slated to enter service in 2011 to produce 12K to 50K tow sizes, says the company. Meanwhile, the company’s Grimsby facility, which produces 600 metric tonnes (1.32 million lb) of Starox oxidized PAN fiber per annum, began carbon fiber production in 2009 on a line capable of 600 metric tonnes per year.

_________________________________________________________________________

Association for the carbon fiber value chain

Carbon Composites e.V. (Augsburg, Germany) touted its large and growing network of members with various competencies that reportedly span the carbon fiber value chain. Established in March 2007, the organization now boasts 100 members, including new automotive members, says the group. Members range from university and research groups to EADS Innovation Works (Munich, Germany), with a shared goal of networking and technology transfer.

_________________________________________________________________________

Net-shape parts out of the mold

The Carbone Forgé (Lentilly, France) stand was as popular as it was last year. The company showcased its expertise in high-pressure molding of net-shape complex and hollow parts (using integral metallic inserts) that require no machining after cure. Working in both thermoset and thermoplastics, the company produces aerospace components as well as parts for sporting goods and other innovations. These include Look bicycle parts, using a proprietary mandrel made from “fusible core” washout material. Carbone Forgé is part of a group of European aerospace companies focused on improving the understanding of in-mold behavior of composite materials and simulating that behavior to create one-piece parts with complex geometries.

_________________________________________________________________________

Semipermanent hybrid mold release

Chem-Trend (Hamburg, Germany) brought to the show Chemlease 2185, a semipermanent, hybrid release agent designed to enable users to transition more easily from wax-based to semipermanent release technology. Like a conventional wax, the new semipermanent agent is visible to the operator during application and can be applied within standard processing temperature ranges. The cure time is about 30 minutes.

_________________________________________________________________________

Offline AFP programming software

Coriolis Composites SAS (Quéven, France), which manufactures automated fiber placement machinery and systems, introduced CATFiber, an offline fiber placement and programming solution designed for use with CATIA and Delmia CAD/CAM systems (both from Dassault Systèmes, Paris, France). CATFiber provides CAD/CAM service from design through fiber placement programming, with design and manufacturing associativity and dedicated toolpath actions.

_________________________________________________________________________

Epoxy for liquid closed molding

Cytec Engineered Materials (Tempe, Ariz.) showcased its new PRISM EP 2400 liquid infusion resin system. The one-part, toughened epoxy, which cures at 350°F/180°C, is targeted to aerospace primary structure and “high-performance industrial” markets, says the company, and it can be used with a wide range of reinforcements. With a novel toughening system and wide processing window, the resin reportedly delivers laminate properties equivalent to Cytec’s 977-2 prepreg.

_________________________________________________________________________

Composite aircraft structures

Tier 1 composite parts supplier Duqueine Group (Massieux, France) showcased its capability as an Airbus partner/supplier. It is producing fuselage frames, window frames and acoustic panels for engine nacelles for the Airbus A350 XWB. The company offered visitors a range of processing options, including hand layup, resin transfer molding (RTM), infusion molding and a unique patented process it calls MFP, which involves compression stamping of random bundles of chopped prepreg used for small parts with complex geometry. The company reports that it will open a new manufacturing facility in Mexico by the end of 2010.

_________________________________________________________________________

Metal matrix composites

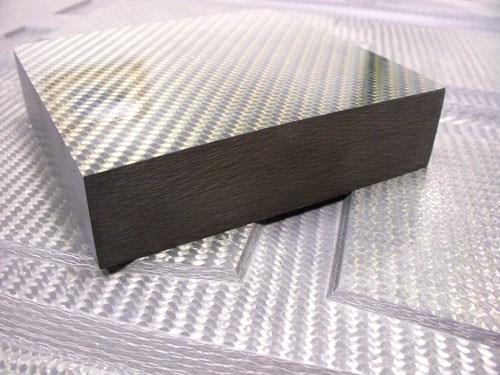

DWA Aluminum Composites USA Inc. (Chatsworth, Calif.), a first-time exhibitor at the show, received considerable attention for its metal matrix composite (MMC) technology. The company produces machinable billets, as well as other shapes as large as 1,000 lb/455 kg, by combining silicon carbide (SiC) particles with aluminum powder. The mixture is vacuum hot pressed to form an aluminum metal matrix composite. According to the company, the material has the same density as aluminum but has higher fatigue resistance and tailored stiffness for solving “compelling” material problems.

_________________________________________________________________________

Pressure vessel for fuel-cell powered vehicle

EADS Composites Aquitaine (Salaunes, France), one of 11 companies represented at the expansive L’Aquitaine Composite stand, held a press event to describe its recent work on fabricating a 700-bar/10,150-psi pressure vessel for liquid hydrogen in partnership with Paris, France-based Air Liquide. The 2.4-liter/0.63-gal vessel is part of a 250-watt fuel cell system that powers a unique tricycle, a vehicle that the company hopes will boost awareness of clean energy for broader automotive applications. Also on display was an ultralight helicopter fuselage in carbon/epoxy for Hélicoptères Guimbal’s (Les Milles, France) Cabri 2, which incorporates crash-resistant technology.

_________________________________________________________________________

Thermoplastic AFP with ultrasonic tack

Fokker Aerostructures BV’s (Hoogeveen, The Netherlands) stand featured an automated fiber placement machine with the company’s new thermoplastic fiber handling system, which uses ultrasonic energy to tack the applied unidirectional plies together (the part is processed in an oven or autoclave). The company is involved in the TAPAS (thermoplastic affordable primary aircraft structure) project, together with Airbus, and it showed a design concept of a horizontal tail with butt-joint stiffening ribs. Regular live fiber placement demonstrations attracted a lot of interest from visitors.

_________________________________________________________________________

Multiaxial fabrics source

Formax UK Ltd. (Leicester, U.K.) held an informal press conference at its stand to highlight the company’s 10-year anniversary, complete with chocolate cake. The multiaxial fabrics manufacturer — the second largest in Europe for carbon multiaxials — offers thousands of products, each customizable for a customer’s needs. Fabrics are manufactured on machinery built by Karl Mayer Textilmaschinenfabrik GmbH (Obertshausen, Germany) that spreads the carbon tow inline for lower ply weight. Target markets include automotive, wind, marine and industrial, and the company reports more than 30 percent growth in revenue per annum. Further, natural fiber fabrics are in the works, says general manager Oliver Wesley.

_________________________________________________________________________

Laser bonding for carbon fiber thermoplastics

The Fraunhofer Institute for Chemical Technology (ICT) (Aachen, Germany) demonstrated bonding of composite structures using laser technology. The system uses carbon fiber tapes impregnated with a thermoplastic resin. These carbon fiber prepreg tapes are placed in a tool, after which an infrared laser heats the thermoplastic resin, creating specific and localized melting of the polymer. The entire stack, when it’s complete, is compressed into a compact structure. This fuses the tapes, and because the laser heat is so specific, cooling is said to be rapid. The laser technology also can be used to bond fiberglass structures together as well, Fraunhofer reports. Potential applications include aerospace interiors, rocket tanks and load-bearing structures in cars.

_________________________________________________________________________

Materials supplier adds moldmaking capabilities

Gurit UK (Isle of Wight, U.K.) emphasized its recent acquisition of wind blade moldmaker Suzhou Red Maple Wind (Suzhou, China). Damian Bannister, technical manager of Red Maple, the tooling business of Gurit, noted that the company has a low-cost base, high-capacity system for manufacturing long-life molds with dimensional accuracy of ±0.5 mm (±0.02 inch) and a carbon fiber epoxy mold surface, with electric and liquid heating options, for wind turbine blade production. Bannister said the cost of the prepreg blade molds is about 50 percent of that for comparable tools produced elsewhere in Europe, and the company requires a 50 percent shorter lead time, just 12 weeks from receipt of geometric specifications. The technology, he added, will give his company the opportunity to develop tooling for other applications, and this is seen as the long-term objective. The company is developing a facility for the manufacture of molds for 70m/230-ft blades.

_________________________________________________________________________

Resin-impregnated peel plies

Henkel AG & Co. KGaA (Toulouse, France) introduced Hysol EA 9895 WPP and 9896 WPP, its new resin-impregnated wet peel plies. Supplied in film form, they were designed to increase bonding durability and to eliminate contamination of composite surfaces from dry peel fragments. Hysol EA 9895 is a prepregged polyester for curing at 177°C/350°F. Hysol EA 9896 WPP is a prepregged nylon for curing at 121°C/250°F.

_________________________________________________________________________

Small-denier intermediate modulus carbon fiber

Hexcel (Dublin, Calif.) announced HexTow IM10, a new carbon fiber said to be a breakthrough material. The small-denier fiber, a product of the company’s legacy intermediate-modulus fiber technology, exhibits a tensile strength of more than 1,010 ksi and a tensile modulus of 44 Msi, with a tensile strain of 2.1 percent. The company says IM10 provides the highest commercially available tensile strength, which is achieved through a combination of better precursor technology coupled with fiber processing. Other innovations at the show included new HexForce bias-weave fabrics that reduce waste caused by cutting standard weave fabrics to create a ±45°orientation.

_________________________________________________________________________

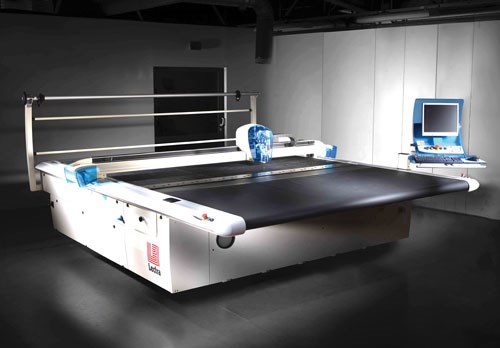

Large-format flatbed cutter

Cutting table manufacturer Lectra (Paris, France) exhibited its new VectorTechTex FX 100 cutting solution for composite materials. Its table is available in widths up to 3m/9.8 ft and lengths up to 4m/13.1 ft. It can cut prepregged carbon fiber and provides multilayer cutting of dry materials, such as reinforcement fabrics and honeycomb. It is said to be best suited for large-format cutting applications, particularly in the case of wind turbine blade manufacturing. The table features new electronics, a new frame, a new vacuum turbine and a databus that reads system signals and looks for potential failures in filters, motors and other equipment based on established thresholds.

_________________________________________________________________________

Expoxy adhesive for honeycomb panel bonding

Magnolia Advanced Materials Inc. (Chamblee, Ga.) emphasized its newest product, Magnabond 5925, a new fire-retardant, two-component, room-temperature-curing epoxy adhesive developed for use in commercial aircraft cabins and anywhere honeycomb panels may be used. It was designed to bond honeycomb panels for aircraft interiors, particularly in “ditch-and-pot” applications. The solvent-free adhesive, said to have good chemical, moisture and environmental resistance, is reportedly suitable for adhesive applications that require an epoxy that is highly resistant to fire.

_________________________________________________________________________

Robotic automation for composites

Matrasur Composites (Marcoussis, France) held a press conference to highlight automation trends in composites and to illustrate the company’s contribution to automating composites fabrication — 5,500 of its robotic units have been installed to date during its 30-year history. According to company spokesman Claude Chouet, the company’s staff of engineers studies each customer’s situation and goals and designs an integrated and affordable robotic solution that can significantly improve productivity. In one example, the company’s industrialization program for a pool manufacturer included automated transfer from work cell to work cell, which resulted in a 67 percent decrease in labor hours per pool, as well as savings in material usage.

_________________________________________________________________________

Expanding carbon fiber capacity

Ordos Yaxin Carbon Fiber Co. (Ordos City, Inner Mongolia, China) had a stand to exhibit its growing carbon fiber production capacity. The company, established in November 2009, claims to be building a 2,000 metric tonne (4.41 million lb) fiber line scheduled to come on line this year, which it says will be China’s largest. Over the next five years, it plans to build eight lines of 1,000 metric tonnes (22.2 million lb) each to achieve a total production of 10,000 tonnes (22 million lb) per annum. The product will be targeted to wind, cabling, automotive and other applications.

_________________________________________________________________________

Spread-tow wovens and unidirectionals

Oxeon (Borås, Sweden) exhibited its trademarked TeXtreme spread tow woven fabrics and TeXero unidirectional tapes. The lightweight materials reduce the weight of composite parts while enhancing their surface finish and mechanical performance, says the company. Oxeon spread tow materials are used for manufacturing a diverse range of products, from high-performance vehicles and aircraft to sports equipment. Future developments may include spread tow natural fiber fabrics, hints Oxeon.

_________________________________________________________________________

Thermoplastic honeycomb core

PlastiCell sarl (Issoire, France) announced the launch of a honeycomb core material manufactured using Victrex USA Inc. (Cleveleys, U.K.) APTIV thermoplastic film (also see Victrex item, below). The film can be thermoformed into shape in combination with fiber-reinforced Victrex PEEK (polyetheretherketone) polymer composite skins to create structural parts without the use of adhesives. Core blocks of the APTIV film can be machined to shape before molding and operate continuously at temperatures up to 220°C/428°F. Structures made with the APTIV/PEEK combination are said to offer good impact resistance and can be used in aerospace and other high-performance applications.

_________________________________________________________________________

New autoclave and AFP machine

Premium AEROTEC GmbH (Augsburg, Germany) — the independent aerospace structures company that was formed on Jan. 1, 2009, formerly known as EADS Augsburg — announced that it is gearing up for series production of the new Airbus A350 XWB. It recently took delivery of a 25m/81-ft long, 8m/26-ft diameter autoclave for curing carbon fiber composite fuselage parts. It is being installed inside a new 25,000m² (269,100-ft²) production facility, currently under construction, to produce the fuselage panels for A350 XWB sections 16 to 18 (rear fuselage). The new building will also include a Viper fiber placement machine supplied by MAG Industrial Automation Systems (Hebron, Ky.) for fabricating the panels.

_________________________________________________________________________

Inductively heated tooling

Roctool Inc. (Le Bourget du Lac, France) exhibited its 3iTech electromagnetic induction technology for tool heating in carbon fiber composite molding. Inductors are integrated inside the mold during manufacturing to match the shape of the part. It provides homogenous heating at the tool surface and can generate heat up to 400°C/752°F in several minutes or 120°C/248°F in a few seconds. The technology, says the company, allows mass, high-speed production of carbon fiber composite parts.

_________________________________________________________________________

New facility in China

Sigmatex (Runcorn, Cheshire, U.K. and Benicia, Calif.) expressed optimism for a turnaround in the coming months, particularly for ballistics and vehicle armor markets. It reports that it has recently opened a new facility in Shanghai, China. The 38,000-ft² (3,530m²) weaving facility is the same size as the company’s U.S. plant.

_________________________________________________________________________

High-performance epoxy resin systems

Sika Deutschland GmbH (Bad Urach, Germany) showcased two new high-performance epoxy resin systems from Sika’s Tooling and Composites group. One, Biresin CR122, is approved for motor glider construction and is optimized for hand layup processes and room temperature cure, providing a service temperature of 120°C/248°F. The second, Biresin CR84, offers a very long pot life (more than 10 hours) for filament winding processes, without dripping, and is targeted to large part fabrication, says the company. Approved by Germanischer Lloyd, the resin is being used to fabricate very large filament-wound tubes for a massive public sculpture designed by Rita McBride, which will be installed in the Effnerplatz in Munich, Germany.

_________________________________________________________________________

Aircraft and space flight thermoplastic prepregs

TenCate Advanced Composites (Nijverdal, The Netherlands and Morgan Hill, Calif.) was a cowinner of the 2010 JEC Innovation Award in the “Aeronautics” category for its trademarked Cetex thermoplastic composite prepreg materials used on the Gulfstream G650 aircraft (also see related item below). The company’s stand featured its Cetex laminate used for a wide variety of aerospace applications, such as brackets for aircraft luggage bins, that are 30 to 40 percent lighter than competing materials while providing better flame, smoke and toxicity (FST) performance. It also featured its ultrahigh-temperature, microcrack-resistant prepreg system developed for the Lockheed Martin Orion spacecraft heat shield (see “XXXXXX,” under Editor's Picks").

_________________________________________________________________________

Net-shape preforms

Toho Tenax Europe GmbH (Wuppertal, Germany) introduced Tenax Net Shape Preforms, which can be made by automated placement of multiple carbon fibers using robotic manufacturing equipment, thereby increasing production speed and improving quality compared to traditional preform products. Applications include substitutes for standard manual preforms and new preform concepts that cannot be executed with current preforming techniques. Aerospace and automotive are targeted markets.

_________________________________________________________________________

One-piece thermoplastic composite vertical tail

Gulfstream Aerospace Corp. (Savannah, Ga.), materials suppliers Ticona (Florence, Ky.) and TenCate Aerospace Composites (Morgan Hill, Calif. and Nijverdal, The Netherlands) and two other Dutch firms, Fokker Aerostructures BV (Hoogeveen, The Netherlands) and KVE Composites Group (The Hague, The Netherlands), held a press conference to discuss the revolutionary thermoplastic composite vertical tail for the Gulfstream 650 aircraft, the winner of the JEC Innovation Award in the “Aeronautics” category and the first external carbon/polyphenylene sulfide (PPS) primary aircraft structure to fly. Made with Ticona’s Fortron PPS resin, prepregged by TenCate, the material is ultrasonically welded using technology developed by KVE, eliminating all metal fasteners. Gulfstream plans to produce 70 to 80 G650 aircraft annually.

_________________________________________________________________________

Glass-filled PEEK polymer

New to Victrex USA Inc. (Thornton Cleveleys, U.K.) PEEK (polyetheretherketone) line of polymers is the ST series, including STG45 (unfilled) and STG45GL30 (30 percent glass filled). Designed for high-temperature applications that require mechanical performance and dimensional stability, the unfilled grade performs in the 150°C to 200°C (302°F to 392°F) range, and the filled grade will work in temperatures higher than 300°C/572°F.

_________________________________________________________________________

Prepreg slit tapes for automated processes

Web Industries Inc. (Marlborough, Mass.), whose custom manufacturing and development of thermoset prepreg slit tapes for tape laying and fiber placement are key to aerospace composites, highlighted its recent expansion in Atlanta, Ga. The larger facility includes the establishment of a composites Research and Development Center.

_________________________________________________________________________

NVD production of stator blade erosion strips

Weber Manufacturing Technologies Inc. (Midland, Ontario, Canada) exhibited a new part that it is manufacturing: nickel vapor deposition (NVD) metal erosion strips for leading edges, targeted to jet engine stator blades. The 0.010-inch/0.254-mm thick strips are produced on an aluminum mandrel and bonded onto a composite fan blade, says the company.

_________________________________________________________________________

Compression molded aircraft seats

xperion GmbH & Co. KG (Herford, Germany) and CDI (Avon, Ohio) announced their new joint venture, Xperion/CDI, which that will be headquartered at CDI’s Avon, Ohio location. Xperion is a former EADS composites division, and CDI, also known as Cutting Dynamics Inc., is a well-known supplier to many aerospace OEMs. In partnership with Boeing, the two companies have developed numerous composite components for the 787 Dreamliner. Principal among these are lightweight aircraft seat backs and frames made with a patented continuous compression molding (CCM) technology. The composite seats meet or exceed performance goals for aluminum materials, and they meet all flame, smoke and toxicity (FST) requirements.

_________________________________________________________________________

Nano-enhanced mold care products

Zyvax Inc. (Ellijay, Ga.) emphasized two new products at its stand. Sealer SF is a mold protectant that uses a nano-based backbone and has no pollutants, odors or emissions. It is designed to increase the duty cycle of any mold, and it protects the mold and component surfaces from wear and damage. The product is thermally stable to 750°F/399°C and can be applied at room temperature. Employing a similar chemistry, including the nano-based backbone, Nano Release is a high-performance release coating that is thermally stable, nonflammable, odor free and free of pollutants and other volatile compounds. Both products are part of the company’s eco-friendly, sustainability product development initiative.

Related Content

Belzona composite wrap restores corroded carbon steel pipeline

Two-part epoxy paste, epoxy structural adhesive, composite wrap and anti-corrosion coating prevent environmental and economic loss for customer.

Read MoreFilm adhesive enables high-temperature bonding

CAMX 2024: Aeroadhere FAE-350-1, Park Aerospace’s curing modified epoxy, offers high toughness with elevated temperature performance when used in primary and secondary aerospace structures.

Read MoreHenkel receives Airbus qualification for European aerospace manufacturing facility

The adhesive company’s Montornès, Spain, plant has been approved as a standard and raw materials supplier for various Airbus platforms, adding to its work in lightweighting, fuel efficiency and automation.

Read MoreBiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More