Coriolis Composites SAS

Z.A. du Mourillon

rue Condorcet

Queven, F-56530 FR

33 2 97 59 94 98

contact@coriolis-composites.com

coriolis-composites.com

About Coriolis Composites SAS

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Coriolis Composites SAS Supplies the Following Products

- Automated fiber placement systems

- CAD/CAM/CAE hardware/software

- Computer controls and software

- Robotic handling equipment

Editorial, News, and Products

-

Post Cure: CFRP landing leg supports reusable launcher capabilities

MT Aerospace AG, as part of the EU’s Horizon Europe project SALTO, has successfully developed a 7-meter-long carbon fiber-reinforced polymer (CFRP) landing leg demonstrator using advanced automated fiber placement and 3D printing technologies.

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

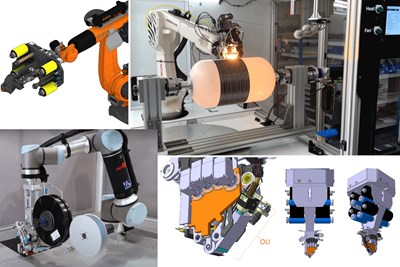

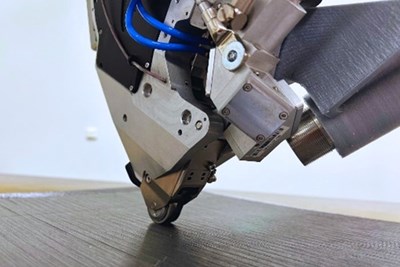

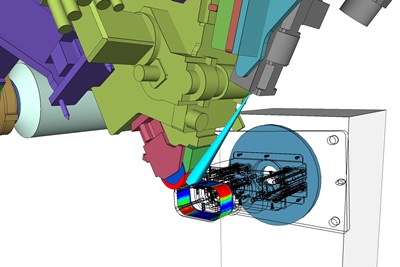

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

-

Coriolis introduces hybrid CPico AFP machine

This compact cell brings together 3D printing, AFP and milling aided by a comprehensive software program, further simplifying the manufacture of complex thermoplastic composite aerostructures in the future.

-

Coriolis highlights C1.2 compact AFP system for multi-material applications

New developments regarding productivity, maintenance and ergonomics make this enhanced composite placement system well suited for the production of complex parts.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

-

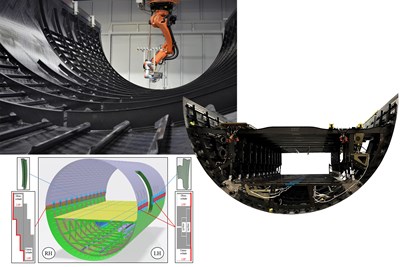

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Heat mapping simulation to improve AFP parts

An optical model developed for Coriolis Composites’ SimuReal AFP process simulation software enables verification of energy distributions during AFP to better define heating laws.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

JEC World 2023 preview

JEC World is the composites industry’s largest trade event, featuring exhibits, presentations and specialized pavilions covering the entire composites industry supply chain.

-

Ultra high-rate composite deposition system trials to surpass layup targets

The NCC, alongside partners Loop Technology, Coriolis and Güdel, are on track to deliver dry fiber deposition rates exceeding 350 kilograms/hour, seven times more than standard aerospace rates.

-

Composites end markets: Aerospace (2023)

With COVID in the past and passengers flying again, commercial aircraft production is ramping up. The aerocomposites supply chain is busy developing new M&P for an approaching next-generation aircraft program.

-

Optimizing AFP for complex-cored CFRP fuselage

Automated process cuts emissions, waste and cost for lightweight RACER helicopter side shells.

-

Plant tour: Avel Robotics, Lorient, France

From AFP hydrofoils to more efficient aircraft parts, Avel uses digital design, multiprocess production and a rule-breaking approach for complex 4D composites.

-

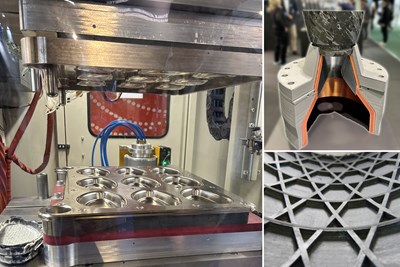

Cannon Tipos, Coriolis Composites mold complex automotive structural part from single preform

Dosing equipment for precise injection and mold engineering enable near-net-shape dry preform for HP-RTM CFRP composite part with rapid cycle time.

-

Coriolis Composites installs AFP machine at Sabanci University

C1 robot contributes to technology development at the Integrated Manufacturing Technologies Research and Application Center (SU IMC) in Istanbul.

-

Plant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

-

SuCoHS project: Advancing composite solutions for parts with high thermal and mechanical loads

New materials, structural concepts and manufacturing using sensors for composites that resist fire, temperature and loads while providing weight and cost savings versus metals.

-

Joby Aviation advances toward FAA certification, highlights Toray prepreg and Coriolis AFP machines

Joby Aviation aims for FAA Part 135 certificate by end of 2022 and launch of commercial service by 2024 as it completes first production-intent aircraft from its pilot manufacturing facility; composites play a key role.

-

Sensors: Data for next-gen composites manufacturing

In the quest for sustainability, sensors are reducing cycle times, energy use and waste, automating closed-loop process control and increasing knowledge to open new possibilities for intelligent manufacturing and structures.

-

NCC’s all-composite Type V tank demonstrates future composite space tank technology

SpaceTank project delivers a 96-liter carbon fiber composite tank with 4.0-5.50-millimeter nominal wall thickness for 30% weight savings in launch vehicle and satellite propellant tank applications.

-

Hengshen to produce rear pressure bulkhead demonstrators

China-based Hengshen Carbon and Composites will produce five 4.5-meter demonstrator composite rear pressure bulkheads (RPB) for a Chinese aerospace OEM.

-

Designing for automated composites manufacturing of low-volume aerostructures

The commercial aerospace industry is heavily focused on design for efficient high-rate manufacturing, but there is still need for automated, affordable fabrication of low-rate aerostructures.

-

Out-of-autoclave VBO rear spar, thermoplastic ribs target Wing of Tomorrow

French Tier 1 aerospace supplier Daher develops out-of-autoclave materials and process technologies for application in next-gen structures for the Airbus Wing of Tomorrow program.

-

Integrating antennas into composite aerostructures

ACASIAS project integrates Ku-band array antenna in novel AFP orthogrid with drastically reduced tooling for more fuel-efficient, multifunctional CFRP aircraft fuselage panel.

-

Cevotec SAMBA Pro Prepreg system added to FPC technology portfolio

Installation of the automated Fiber Patch Placement system in Fraunhofer IGCV’s Fiber Placement Center serves active technology and application development.

-

AFP tow steering comes of age, Part 1: Current state

It used to be enough that AFP systems could precisely and quickly place and cut multiple tows to build complex aerostructures. Now, fabricators need those tows steered, and the tighter the radius, the better.

-

Victrex, Daher, attain next-gen thermoplastic aircraft panel milestone

The developed panel is a 176-ply laminate, 32-millimeter-thick composite structure and uses Victrex AE 250 PAEK-based thermoplastic composites.

-

3D printing CFRP molds for RTM flaperon, exoskeletons and more

The Chair of Carbon Composites at TU Munich is advancing composite additive manufacturing via large-scale extrusion, continuous fiber printing, integrating heating into tools and more.

-

Coriolis Composites and Edixia develop inline inspection for AFP

Video and discussion of how the sensor and software operate to boost composites productivity

-

National Composites Centre unveils digital composites technologies

The U.K.’s National Composites Centre unveils new composites manufacturing technologies, marking the culmination of a two-year, £36.7m digitization project.

-

Compression RTM for production of future aerostructures

Automated preforming and 5-min resin infiltration show a way forward for lower-cost CFRP primary structures.

-

Modular, mobile, multiple robotics poised to change the AFP/ATL paradigm

The German Aerospace Center (DLR) is working on two multi-robot automated fiber and tape placement technologies that could change the paradigm in large-part aerocomposites manufacturing.

-

Consortium targets solutions for carbon fiber thermoplastic composite structures

The HAICoPAS project, led by Hexcel and Arkema, aims to optimize UD tape design and manufacture for aerospace and automotive composites.

-

National Composites Centre purchases Coriolis C5 robotic gantry AFP

Developed for rate production of large, complex composite structures, C5 will be part of world’s most advanced, flexible dry-fiber deposition cell.

-

CGTech joins NIAR to support ATLAS research

CGTech's AFP/ATL programming and simulation software will be used to support ATLAS aerospace composites research at the National Institute of Aviation Research.

-

Plant Tour: STELIA Aerospace, Méaulte, France

Supplier of Airbus fuselage sections pushes boundaries of hybrid aerostructures production, assembly and thermoplastic composites.

-

The Fiber Placement Center of SGL Carbon and Fraunhofer IGCV add Cevotec and Coriolis Composites as partners

Cevotec and Coriolis Composites will contribute their own fiber placement and automation technologies to the FPC facility, which recently celebrated its one-year anniversary.

-

JEC World 2019 preview: Victrex and Coriolis

Victrex (Thornton Cleveleys, U.K., 5/S29) and Coriolis Composites (Queven, France, 6/A32) are announcing cooperative work they did with thermoplastic unidirectional tape (TP UDT) prepreg lay-up and consolidation to improve the manufacturing efficiency of composite parts.

-

New technologies and markets at World of Filament Winding event

Nov. conference features winding developments with robots, automated fiber placement, additive manufacturing and emerging markets.

-

NIAR selects Coriolis Composites to provide thermoplastics capable AFP system

The new system will contribute to NIAR’s technology development efforts in the area of three-dimensional thermoplastics automation.

-

FPC to explore new production concepts for lightweight components

SGL Carbon and Fraunhofer IGCV have officially opened a new Fiber Placement Center in Meitingen, Germany.

-

Coriolis Group acquires filament winding specialist MF TECH

Parent company of Coriolis Composites completes first external growth operation, strengthening its industrial robotics for composites manufacturing.

-

Infused wing sheds light on aerocomposites future

In the Irkut MS-21 infused and co-cured wings, the aerocomposites industry gets a glimpse of how out-of-autoclave technologies might be applied to primary aircraft structures.

-

Plant tour: Israel Aerospace Industries, Ben Gurion International Airport, Israel

Israel Aerospace Industries (IAI) is developing increasing expertise both in and out of the autoclave as it expands an already broad composites production portfolio.

-

Automated Preforming, Part 6: Coriolis Composites

Pioneer in automated fiber placement (AFP) advances preforms for overmolded thermoplastic composites enabling production of one automotive part every 20 seconds.

-

Automation, automotive, recycling and more from JEC World 2018

Mass production of automotive composites, recycling and composites in shipbuilding are just some of the themes from this year’s JEC.

-

Consolidating thermoplastic composite aerostructures in place, Part 2

Thermoplastic composite structures could eliminate the autoclave and fasteners, but will a one- or two-step process prevail?

-

Consolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

-

Thermoplastic composite demonstrators — EU roadmap for future airframes

There is a TPC development roadmap in Europe, supported by Airbus and a variety of aerospace consortia, and involving almost every major aerostructures supplier in Europe.

-

Automated Preforming, Part 3: Quilted Stratum Process

CW’s tour of Cetim and the QSP line which preforms multi-thickness thermoplastic materials in 40-90 seconds for composite parts with cycle times of 1-2 minutes.

-

Automated Preforming, Part 1: Numbers and Landscape

CW’s multi-blog series on preforming begins with an overview and quick look at the numbers: 1-minute take time, 10-15 seconds per layer, 490-kg/hr and 3.5 million parts/year. Are you ready for serial CFRP production?

-

JEC World 2016, the full report

CompositesWorld's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

-

Coriolis unveils automotive composites technologies and products

The parts, displayed at JEC World 2016, include the B-pillar for the Audi A8 and engine mounts developed in cooperation with Cooper Standard.

-

GKN leads “STeM” program to successful conclusion

Technical achievements are credited to successful partner collaboration.

-

Dry fiber placement: Surpassing limits

Coriolis Composites’ automated aerostructures manufacturing using dry materials moves from development projects to production.

-

CFK-Valley Stade Convention 2015 report

The composites industry in Germany is preparing for the 4th Industrial Revolution.

-

Additive manufacturing in automotive applications

Although they have been overshadowed by aerospace applications, 3D-printed tools also are finding a place in automotive processing. Here's one example.

-

Thermoplastic composites technology: A view from Europe

For this Dutch consortium, bringing the manufacturability of thermoplastic materials to maturity is the goal in concert with OEMs, materials and equipment supplier members.

-

CAMX 2014 show report

Bigger, better and more inclusive than any previous U.S. composites trade event, the inaugural show turns North American eyes forward to the future.

-

JEC Europe 2014 Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

Resin-infused MS-21 wings and wingbox

Moscow-based aeromanufacturer uses out-of-autoclave composites in attempt to leapfrog Airbus and Boeing with wider, lighter, more efficient single-aisle airliner.

-

Main landing gear doors designed for all contingencies

For the Airbus XWB airliner, they must meet strict structural, aerodynamic, emergency and aesthetic requirements.

-

2013 JEC Europe new product showcase

The JEC Europe 2013 trade show (March 12-14, at the Paris Expo, Porte de Versailles, Paris, France) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the HPC editorial staff's compilation of what was on display.

-

Composites automation: Trending smaller and robotic

Although AFP and automated tape laying (ATL) lamination technologies are widely used in the aircraft industry, market conditions in the past few years are driving some changes in composites equipment supplier product lines. Consultant Carroll Grant explains why.

-

Status update on composites automation

Consultant Carroll Grant reviews progress made in recent years toward greater variety in automated composites processing machine sizes configurations and capabilities.

-

2010 SAMPE Europe/JEC Paris Showcase

Record crowds and reignited technological development testified to the composite industry’s renewed health and the recent recession’s demise.