Composites manufacturing is notoriously varied. The mix of resin, fibers and processes creates a vast universe of manufacturing options that can be difficult to track and quantify. That said, such tracking and quantifying is worth doing, if only to help establish for the composites industry some baseline data regarding operations efficiency.

With that in mind, CompositesWorld, in cooperation with Gardner Intelligence, has launched the CW Top Shops benchmarking survey, designed to help composites manufacturing operations like yours measure and assess how well they compare to other composites manufacturers.

2019 CW Top Shops winners. These 31 top-ranked facilities earned the Top Shops label.

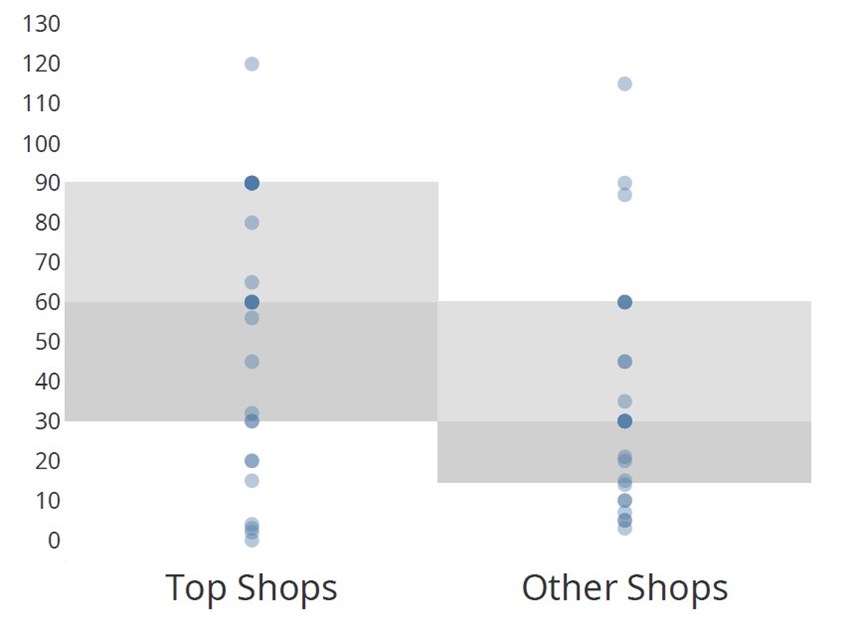

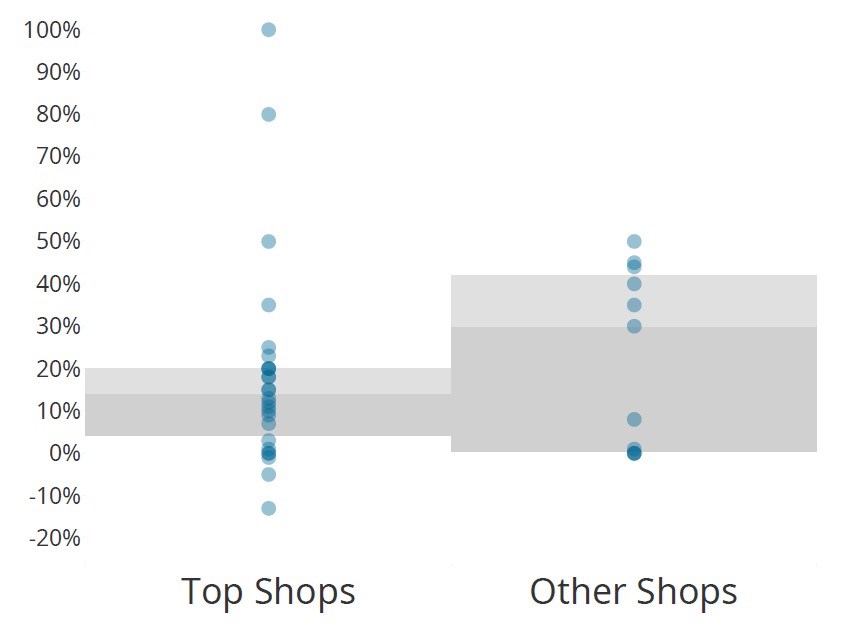

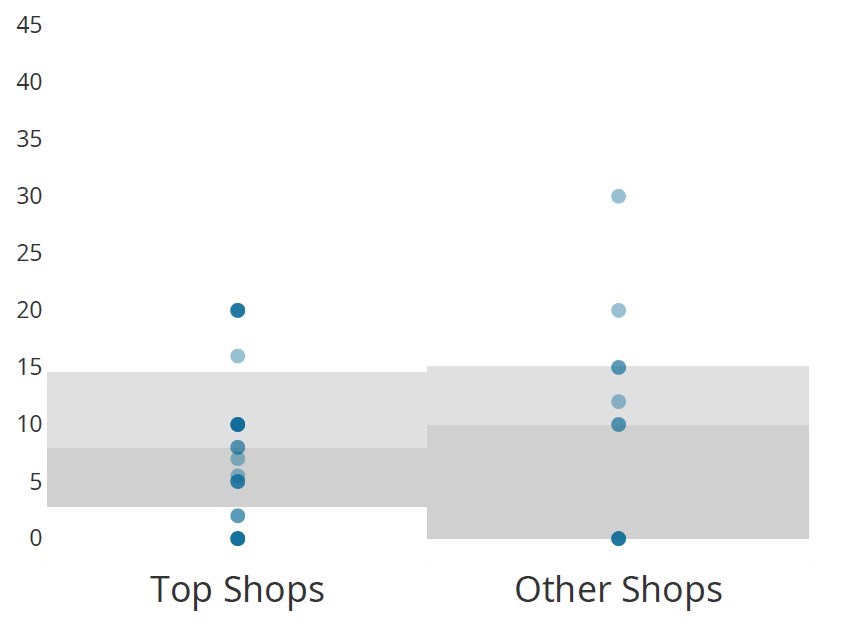

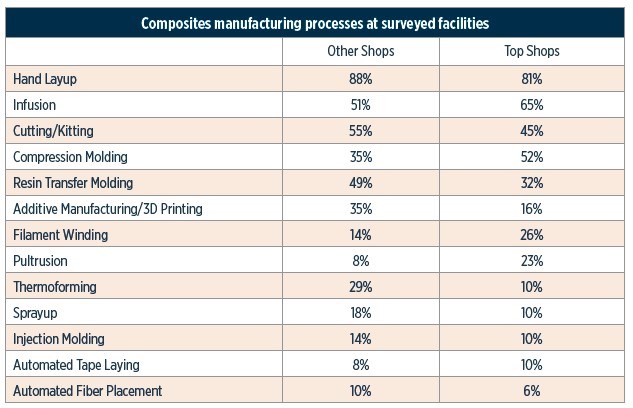

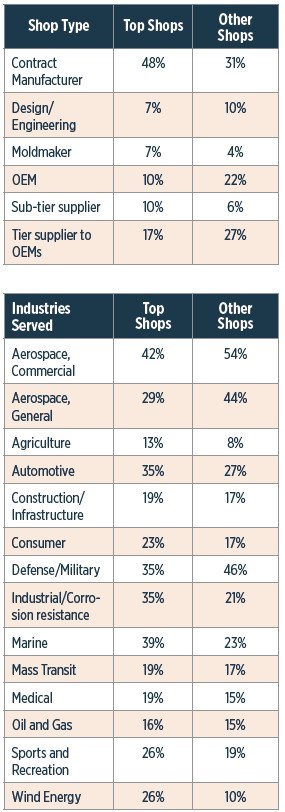

We asked composites fabricators — individual facilities — to provide a host of data surrounding several metrics including order lead time, machine uptime, capacity utilization, wages, customer retention, sales growth, labor turnover, scrap rate, materials used, processes used, inspection technologies used, inspection machinery employed, supply chain practices, marketing practices, certifications and much more. We received more than 110 survey responses.

The charts and graphs in this report aggregate all of those responses, which came from composites fabricators from around the world representing every major end market, including aerospace, automotive, marine, energy, consumer and industrial.

We then ranked each facility for each metric, which in turn gave us an overall ranking for each facility. The top 30 facilities (actually 31 as we had a tie) in our survey earned the Top Shops label, which we hope will become a highly coveted and respected badge of honor.

What follows here is a sampling of CW Top Shops survey results, designed to give you a sense for the kind of data we collected, and where our respondents fell. Every facility that participates in the CW Top Shops survey gets the full report free. However, if your facility did not participate, and if you would like to see the full results, you can purchase the CompositesWorld Benchmarking Standards Report at the Gardner Intelligence website. Cost is $395.

If your facility did not participate in the 2019 CW Top Shops survey, we encourage you to keep an eye out for the 2020 CW Top Shops survey, which will launch early next year. Keep an eye out for an announcement in the CW Today newsletter, or send me a note at jeff@compositesworld.com and I will make sure you are on the distribution for the 2020 survey.

Many thanks to everyone who participated in the inaugural CW Top Shops survey.

Related Content

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Next-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.