3-D preformed composites: The leap into LEAP

The LEAP jet engine is the next generation of the successful CFM56 engine for narrow-body aircraft which powers more than half of the commercial aircraft ordered in the past decade.

The LEAP jet engine is the next generation of the successful CFM56 engine for narrow-body aircraft which powers more than half of the commercial aircraft ordered in the past decade. Produced by CFM International (Evry, France and Cincinnati, Ohio) — a 50/50 joint venture of Snecma and GE, formed in 1974. Snecma/Safran (Paris, France) is responsible for the low-pressure fan sections and GE Aviation handles the high-pressure combustion core. LEAP reportedly will offer a 15 percent reduction in fuel consumption and CO2 emissions, the lowest operating cost (thanks to less maintenance and longer intervals between service) and an aircraft departure reliability of 99.98 percent. The 3-D woven resin transfer molded (RTM) composites developed by Safran and AEC are a key enabling technology in LEAP’s ability to achieve this high performance (see Fig. 2).

LEAP will use 18 carbon fiber-reinforced polymer (CFRP) blades that together weigh 168 lb/76 kg. The CFM56 has 36 titanium fan blades, totaling 330 lb/150 kg. Lighter composite blades produce less energy that must be absorbed in a blade-out situation, allowing a less massive containment system. Also, a less weighty fan disk can be used to hold the blades in place. The weight savings cascade through other structures for a total 1,000 lb/454 kg reduction per aircraft. The LEAP blade’s aero-acoustic 3-D swept geometry helps to reduce overall engine noise and to meet International Civil Aviation Organization’s (ICAO, Montréal, Québec, Canada) Chapter 5 noise regulations.

Bird impact was a limiting design factor for the fan blade. A challenge for the 128-inch/3m diameter fan in the precedingGE90 engine, bird impact is magnified in the LEAP engine because on its smaller 78-inch/2m diameter fan — the first for single-aisle aircraft to use composites — the smaller blades offer less area to absorb the same impact energy.

The 3-D woven preform developed by Snecma and Albany Engineered Composites (AEC, Rochester, N.H.) results in a composite blade without any inherently weak, unreinforced planes that could be susceptible to delamination failures — an advantage vs. laminates that feature traditional 2-D fabrics. As dictated by the design of the 3-D fiber architecture, “layers” in the blade are interconnected with fiber so that both the through-thickness and in-plane properties of the blade are fiber dominated. In various “zones” of the blade, there are different in-plane and out-of-plane loads experienced in service, and these zones each require unique 3-D woven architectures, tailored to meet their structural requirements.

In addition to the blades, three other LEAP parts use AEC 3-D woven RTM composites: fan case, platforms and spacers. Platforms form the flow path between blades, while spacers are effectively springs that keep the blade in position while the engine is not spinning. 3-D woven technology is being evaluated for additional fan module components and also for ceramic-matrix composite (CMC) applications.

Where fan cases have previously used a metallic ring with or without an aramid fiber over-wrap, the LEAP fan case — incorporating AEC’s contour weaving and 3-D preform technology — will be the first to integrate the containment into the case via a carbon fiber 3-D structure, eliminating separate manufacture, assembly and excess weight. The carbon fan case cuts weight 30 percent versus aluminum. The 3-D preform enables a shaped cross-section with an integral flange on each edge and meets stringent fan blade-out test requirements.

This short article is a sidebar to a feature aritcle titled "Albany Engineered Composites: Weaving the future in 3-D." To read this artice, clikc on its title under "Editor's Picks," at top right.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

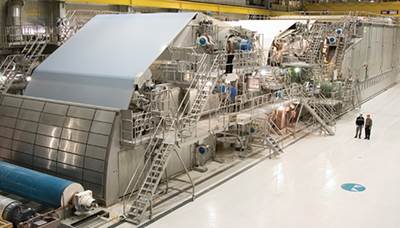

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

Albany International: Multilayer to multidimensional

Albany International (Rochester, N.H.) has a half-century of experience in producing multilayer technical textiles to meet demanding performance and cost expectations.

Read MoreAlbany Engineered Composites: Weaving the Future in 3-D

This 3-D weaver turned composite component supplier pursues a future in 3-D structures through continuous technology development.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More