35th Space Symposium puts emphasis on collaboration, U.S. leadership in space

High-profile speakers at the 35th Space Symposium emphasized the need to increase collaboration with commercial entities and foreign partners to maintain U.S. dominance in space.

Recently CW attended the 35th Space Symposium in Colorado Springs, Colo., U.S. The event was an exciting look at what appears to be the very near future of space exploration. There was an undercurrent of urgency as high-profile speakers including Acting Defense Secretary Patrick Shanahan, Air Force Secretary Heather Wilson and Air Force Chief of Staff Gen. David L. Goldfein emphasized the importance of the U.S. working to maintain dominance in space in terms of both exploration and defense. Speakers emphasized the need to increase collaboration with commercial entities and foreign partners.

National Aeronautics and Space Administration (NASA, Washington, D.C., U.S.) administrator Jim Bridenstine offered the agency’s response to an address by U.S. Vice President Mike Pence at a meeting of the National Space Council on March 26, which called for a return to the Moon by U.S. astronauts by the year 2024. Bridenstine explained how the agency plans to achieve such a monumental goal in the accelerated timeline by moving up programs that were already in development:

- The Space Launch System (SLS) – NASA’s launch vehicle aimed at enabling exploration beyond Earth’s orbit. SLS has a core stage built by the Boeing Company (Huntsville, Ala., U.S.) and employs engines from Aerojet Rocketdyne (Sacramento, Calif., U.S.) and boosters from Northrop Grumman (Falls Church, Va., U.S.).

- The Orion Multi-Purpose Crew Vehicle consisting of a command module manufactured by Lockheed Martin (Bethesda, Md., U.S.) and a service module provided by the European Space Agency (ESA, Paris, France) and being built by Airbus Defence and Space (Ottobrunn, Germany). Orion is planned for use for Moon exploration as well as future missions to Mars and asteroids. (Read CW’s report on the making of Orion’s composite heat shield.)

- The Lunar Orbital Platform-Gateway (LOP-G), a lunar-orbit space station being developed by NASA along with international partners.

“All of this was already planned for 2028. We’re just going to accelerate pieces of it,” said Bridenstine.

Bridenstine also referenced the Mars 2020 mission, which is set to launch in the summer of 2020 with the goal of putting a new robotic rover as well as a carbon fiber helicopter on the red planet.

See CW’s coverage of the Mars helicopter.

Walking through the exhibition floor, a sense of commercial space’s role in the national space program was palpable. Small satellite launchers like Rocket Lab (Huntington Beach, Calif. , U.S.) had a large presence in the main exhibit hall. Crew members of Virgin Galactic Spaceship Two’s second spaceflight were presented with their Commercial Astronaut Wings by the Federal Aviation Administration (FAA), and Virgin Galactic founder Richard Branson was presented the Space Achievement award at the symposium’s closing dinner.

See CW’s coverage of the making of Virgin Galactic’s carbon fiber spacecraft.

Engines and various components (including many composite ones such as payload fairing and pressure vessels) that play roles in such launch systems as the SLS and the Vulcan Centaur rocket were on display. Various mock-ups of the Orion spacecraft and the Gateway lunar base were featured in booths of companies contributing technology to the programs. Numerous companies announced new intiatives — many of them offering some insight into the role composites play in today’s space race.

United Launch Alliance (ULA, Centennial, Colo., U.S.) reported continued progress of the manufacture of its Vulcan Centaur launch vehicle, scheduled for launch in 2021. The ULA plans to begin flying Vulcan hardware on Atlas 5 rockets during 2019 in order to gain flight heritage before the next-generation launcher debuts. Out-of-autoclave manufactured payload fairings from RUAG (Bern, Switzerland; renamed to Beyond Gravity) will be among the first Vulcan technology to fly on Atlas 5. (See the news post on ULA’s Vulcan Centaur update).

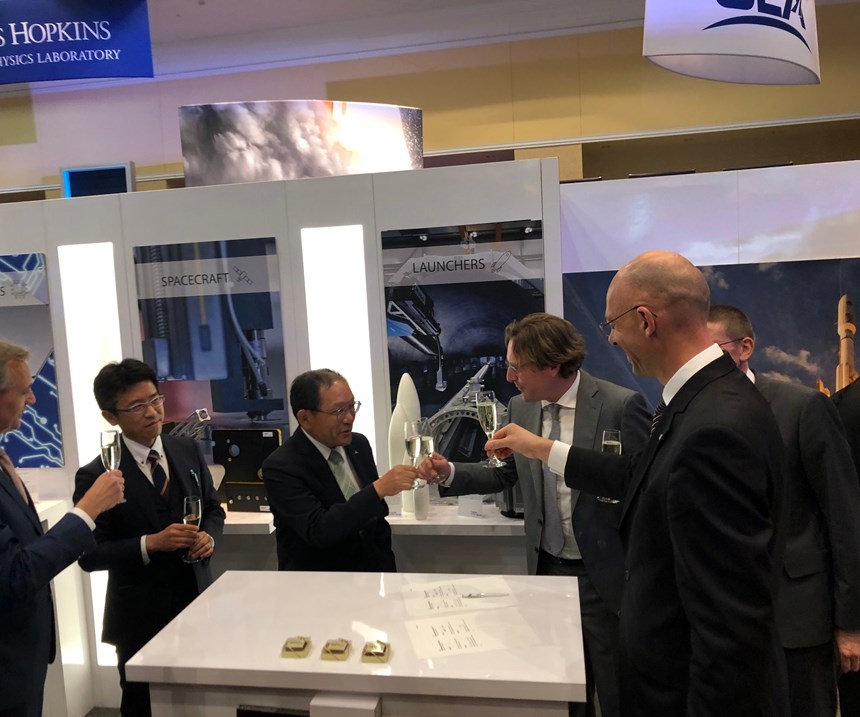

RUAG also signed a contract with Mitsubishi Heavy Industries (MHI,) during the Space Symposium. RUAG will supply composite payload fairings and supporting structures for Mitsubishi’s H3 launch vehicle for three resupply missions to the International Space Station. (See the news post on RUAG’s agreement with MHI).

An update on the James Webb Space Telescope was presented by project manager Bill Ochs, project head Dr. Massimo Stiavelli and Scott Willoughby, Northrop Grumman Aerospace Systems vice president. The telescope employs carbon fiber composites to support its Optical Telescope Element (OTE), and also in its Space Craft Element (SCE) which includes an integrated heat shield and spacecraft bus.

See CW’s coverage of the James Webb Space Telescope’s composite primary mirror backplane support structure.

We are living in exciting times. This year marks the 50th anniversary of the start of the Apollo program as the nation looks to return to the Moon within five years. In the meantime, the U.S. is competing with aggressive space programs from rival nations — China reportedly launched one-third of the world’s total space missions during 2018. A whole new race for space dominance is clearly on. If competition breeds innovation, the stage seems to be set for commercial space’s role to continue to grow, offering plenty of opportunity for aerospace manufacturers. Carbon fiber and advanced materials obviously have a large role to play — it will be exciting to see how composites enable this next giant leap for humanity.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlataine unveils AI-based autoclave scheduling optimization tool

The Autoclave Scheduler is designed to increase autoclave throughput, save operational costs and energy, and contribute to sustainable composite manufacturing.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More