3D printed composites with 60% fiber, less than 1% voids

9T Labs advances continuous carbon fiber 3D printing for industrial series structural components.

“Our main goal is to produce structural continuous fiber composites for industry,” says 9T Labs (Zurich, Switzerland) co-founder Giovanni Cavolina. “If you talk to people who manufacture CFRP (carbon fiber reinforced polymer) parts, most don’t believe that it’s possible to achieve super-low void content or good interlaminar shear strength (ILSS) between layers with continuous fiber 3D printing.” 9T Labs, however, has developed a patented post-process that eliminates voids. “We can now 3D print continuous fiber composites with great adhesion between layers and void content below 1 percent, which competes with conventionally manufactured composites.”

Beginning at ETH Zurich

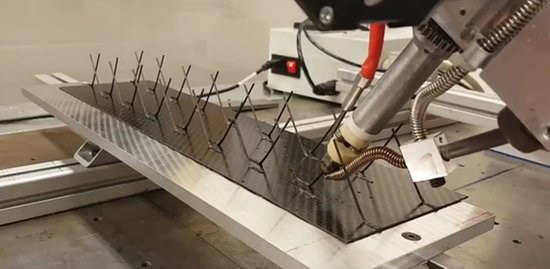

9T Labs started with a research project in the Laboratory of Composite Materials and Adaptive Structures (CMAS) at the Swiss Federal Institute of Technology Zurich (ETH Zurich). Cavolina and 9T Labs co-founders Martin Eichenhofer and Chester Houwink had developed a composites printhead, “which we mounted onto a robotic arm and made lattice cores for ultra-lightweight sandwich structures, targeted for aerospace applications,” Cavolina explains.

CFRP lattice structures produced as part of the Carbon Factory project at CMAS, ETH Zurich. SOURCE | Carbon Factory, CMAS.

The team received a lot of interest from industry, notes Cavolina, “but we realized that these types of lattice structures — i.e., extruding rods into free space — just didn’t have enough near-term potential for commercial applications at this point. It shows great technical potential for what is possible, but a lot of extreme R&D is still required to bring such a process to automation, yet the applications are niche, not widespread.”

The companies that contacted the group were actually asking for something quite different. “They wanted a process to create brackets and other monolithic parts that they could use now. We then had to consider how to proceed.”

CarbonKit was a limited release product that enabled off-the-shelf FDM printers to use continuous carbon fiber but was not yet the right solution for producing cost-competitive, industry CFRP structural parts. SOURCE | 9T Labs.

CarbonKit

Thus, 9T Labs was established at the beginning of 2018 to prove the concept of 3D printing monolithic CFRP laminates that could meet potential customer requirements. “Our next step was the CarbonKit,” says Cavolina. This is the product that is featured in CW’s March 2019 article “Moving continuous fiber 3D printing into production”. The CarbonKit transforms Ultimaker or Prusa 3D printers into a system capable of printing with continuous carbon fiber. “It allows you to use your existing printers in combination with our printhead, filaments and software to place continuous fibers, according to the load case, with 50 percent carbon fiber volume content — not 30 percent, which has been the norm in CFRP 3d printing,” he adds.

Cavolina explains that even though the interest in this product was quite large, “we only supplied 25 customers. We kept this product limited because we realized that with only a one-step FDM [fused deposition modeling] process, it’s not possible to achieve structural end-use parts for industrial aerospace applications that are also cost-competitive with current technologies.”

However, through the CarbonKit, 9T Labs established valuable customer relationships. “We were able to learn what companies expected and needed, even though these parts were actually not possible to produce with the CarbonKit,” he explains. “In situ consolidation is indeed possible with FDM, but it would require much more complex machines that are cost-prohibitive. So, we produced a 2-step process with a post-print consolidation.”

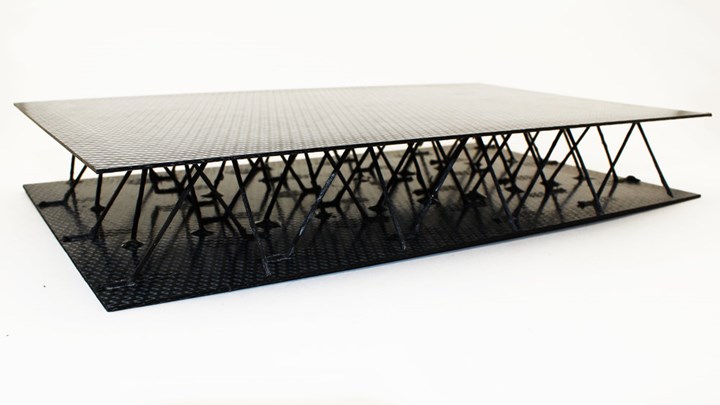

With Red Series, 9T Labs has achieved 3D printed CFRP structures with >50% fiber volume and <1% voids at an affordable cost vs. current composites production methods. SOURCE | 9T Labs.

Red Series, 2-step process

That brings us to where 9T Labs is today. “We are commercializing the Red Series, which comprises two units: a classical FDM printing unit with a patented print head and an adjacent Fusion Unit for post-processing,” Cavolina explains. “We don’t achieve full in-situ consolidation during printing, but instead print and then consolidate in a second process. In essence, we are printing a preform which is placed in the Fusion Unit for post-consolidation using high temperature and pressure to achieve more than 50 percent fiber volume content with less than 1 percent voids. This 2-step process achieves aerospace quality at an affordable cost.”

The Red Series uses thermoplastic materials, for now. “We print carbon fiber with PEI, PEKK, PA (nylon) and have experience with PP as well,” says Cavolina. Is the Red Series an open-materials system? “The only way to be cost-competitive is to use existing materials with a new manufacturing process,” he explains. “If you come up with your own material from scratch, you exclude being able to go into series manufacturing. For supply chain security and reliability reasons, series manufacturers will not rely on a small company for their materials. So, we let our customers use their existing materials supply, by making sure the materials work in our system.” He explains that 9T Labs tests the materials to make sure the feedstock fulfills certain requirements and determines the best parameters for printing.

What about open software? “Our print software is combined with a structural simulation software,” says Cavolina. “It’s great as an engineer to place fibers where needed but how can you be sure this is indeed where they should be placed? Our software gives the freedom to design and then cross-check with a structural simulation. The other direction is to define a fiber-oriented layup in a structural simulation and then convert it into a print path in our software. We use an existing, well-tried and well-known partner for the FEA that runs in the background. You can also directly design a part in CAD and then upload that file into our program. There, you decide where you want the carbon fiber and where neat polymer is sufficient.”

This CFRP bracket and rocker arm for non-aerospace applications actually meet aerospace laminate requirements and feature more than 40 plies — each ply with a different fiber orientation to exploit anisotropy and optimize structural parts not previously possible. SOURCE | 9T Labs.

Applications

9T Labs is pursuing aerospace (interiors, for now), biomedical and industrial automation (e.g., packaging machines), as well as leisure/luxury (e.g., motorsports, sport shoes, eyeglasses). This last market, says Cavolina, “is where you need to have structural composites, but the requirements are not as stringent as in aerospace.” He cites the rocker arm shown above. “This is a bracket for a non-aerospace structure that represents a structural application that you can produce in an optimized way using our technology,” he explains. “It comes from an aluminum part that has been topology optimized to save weight by orienting carbon fibers according to the load case. You can save cost because you can reduce the amount of carbon fiber used versus other composites processes. You cannot make it by other means because it is not possible with other methods to orient every fiber as you need to in high resolution.”

Four different continuous carbon fiber layups are alternated throughout the thickness of the CFRP bracket printed with 9T Labs Red Series. SOURCE | 9T Labs.

Cavolina notes this rocker arm comprises more than 40 layers of fiber and polymer, “and we can have a different fiber orientations in every layer. We tried four different layups, not restricted to quasi-isotropic. This freedom allows us to exploit the anisotropy of composites to further optimize the end-use structure. It would not be possible to do this with other current manufacturing methods.”

He also points out that 3D printing CFRP is an automated process compared to hand layup. “Our technology drastically reduces manual labor via automated layup,” says Cavolina. “With our technology, you just print, consolidate and you’re done.”

The Red Series prints smaller, complex, monolithic CFRP preforms which are then consolidated in a second step for scalable industrial series production. SOURCE | 9T Labs.

Red Series print size, speed and full launch

The Red Series is aimed at smaller, monolithic parts for series manufacturing within a print area of 350 millimeters by 300 millimeters. “here we see at the moment the highest added value for our customers,” Cavolina explains.

What about print speed? “We’re talking in a very concrete way about producing in the next 1-2 years 4,000 to 8,000 parts per year for different customers, achieved with the Red Series twin units,” says Cavolina. “Because we have decoupled production of complex, detailed preforms from consolidation, it is now possible to ramp up production volume quickly.”

“We have spent a lot of time analyzing the cost structure of our process, including equipment, labor and material costs,” he responds. “We have an affordable equipment cost structure and have automated the preforming process. We use materials that are the most affordable and efficient, and then reduce the amount of material required by orienting the fibers per the load case and using structural optimization. We work closely with our partners in structural and process simulation and see that it will continue to grow as a large part of the production goal of using digital twin technology to enable plug and play with 4.0 production lines and cells.”

The Red Series will launch in 2020. “Now, we are evaluating it through our collaboration programs with production partners. We certify the parts and processes with them, so they have reserved the first slots for Red Series machines and will use these to manufacture their end-use products.”

Related Content

New Flyer selects Hexagon Purus H2 tanks for fifth consecutive year

Type 4 tanks will continue to be supplied for the mass mobility provider’s Xcelsior Charge FC fuel cell electric transit buses.

Read MoreBüfa partners with Končar to develop composite electric rail platform

Končar-Električna to use Büfa fire-retardant composite materials for electric vehicle development.

Read MoreComposites reinvent transportation

Celebrating National Composites Week, CW shares ways in which composites continue to evolve mass transit.

Read MoreComposite sidewall cover expands options for fire-safe rail components

R&D project by CG Rail explores use of carbon fiber-reinforced thermoplastics and recycled manufacturing scrap to meet fire safety, weight and volume targets.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More