3D Printing continuous carbon fiber composites?

Additive manufacturing startup MarkForged aims to make it happen and is already marketing systems.

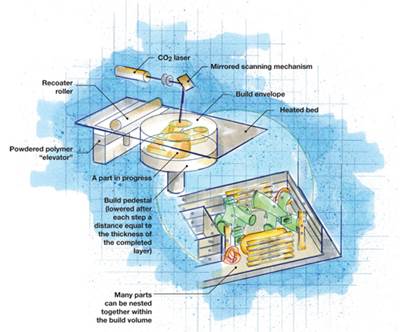

Additive manufacturing (AM) is one of the hottest areas in parts fabrication. Interest is high, research dollars are being spent and company stocks are attracting investor attention. Why? First, because AM has moved beyond its initial role as a prototyping tool to a process that can build finished parts. AM technologies — stereolithography, fused deposition modeling (FDM), laser sintering (LS), material extrusion, direct metal deposition and more (see "The rise of rapid manufacturing," under “Editor's Picks,” at top right) — were able from their beginnings to accurately form complex, three-dimensional parts directly, without tooling or touch labor. They build them up in stacked, horizontal layers from digital design files (hence, the moniker “3-D printing”). But those early technologies came with some technical challenges that — particularly in the composites industry — limited their utility. Although they could produce a part, or multiple small parts, faster than many molding processes, early AM devices used low-end, unreinforced commodity thermoplastics or metals. In addition, machine build enclosures were small, limiting part size. Most importantly, they could easily duplicate part dimensions within specified tolerances but rarely delivered the mechanical properties necessary in a finished part. In recent years, however, refined 3-D printers have built parts from a wider range of tougher, stronger materials. Beyond the “cool” factor, these processes now have enormous appeal to industry. Indeed, many OEMs, including The Boeing Co. (Chicago, Ill.) and GE (Fairfield, Conn.), have already adopted the technology for complex parts that are flying on aircraft.

But until recently, AM offered no viable alternative to molders of high-performance composites. Some machines can form parts using reinforced plastics, but only very short fibers can pass through the deposition heads. Part strength and stiffness, therefore, could not match that achieved with continuous fibers.

A new era of instant awesomeness

A recent arrival on the AM scene, MarkForged (Cambridge, Mass.) is charting a course that could change that. A small startup, opened in early 2013 by MIT-educated aerospace engineer Greg Mark, it is a spin-off from Mark’s Aeromotions company, which produces computer-controlled carbon fiber wings for race cars. Although his experience with composites began with wet layup, he says, “we then moved to prepreg construction and autoclave cure and, finally, to out-of-autoclave infusion.” But, regardless of the method, the time required to make molds, obtain materials, and then lay up and cure the parts was not trivial — nor was the cost, he adds.

“That motivated us to develop our printing technology,” Mark explains. “Our vision was always to make end-use parts, but a lot more efficiently. We wanted to use the mechanics of a 3-D printer to automate carbon fiber composite layup.” R&D was initially based on open-source 3-D printers, which the company refined iteratively to create a more robust and reliable process. The result is an AM printer that can produce parts made with continuous carbon fiber in a thermoplastic resin. Because MarkForged is, thus far, unique in its use of continuous reinforcements, Mark says, “we really had to think about controlling the print process with the machine’s software.” The Mark One machine was unveiled at the recent SOLIDWORKS World 2014 conference (see “Two visions of 3-D printing in CFRP,” under "Editor's Picks").

Unlike typical AM machinery, the Mark One has two print heads, both designed and built by the company. One dispenses polyamide (nylon) or polylactide (PLA) resin, and the second dispenses a continuous towpreg, either carbon or glass (dispensing of aramid fiber is in development). The towpreg is made in a proprietary process: A single carbon filament is coated with a specially developed thermoplastic resin, designed specifically for the printer. The Mark One uses FDM, an extrusion-like process, for placement of resin and towpreg in the flat x/y plane of the part. Mark says that the fiber can be oriented, or added selectively only where needed, in the x/y plane, but notes that, at present, vertical, or z-directional, orientations aren’t possible. Each build layer is approximately 200 microns in thickness.

Says Mark, “The machine’s software can choose the optimal fiber orientation based on some basic design rules, or in the manual mode, you can specify the orientation on a layer-by-layer basis, to allow for specific placement, for example, ±45°.” MarkForged is currently designing plug-ins to work with the major computer-aided design (CAD) programmers, including Dassault Systèmes (Waltham, Mass.), so that, eventually, any design software can be used to drive the machine for optimal fiber placement.

The “stage” on which deposition takes place is a plastic platform, to which the polyamide or PLA resin adheres, similar to other AM machines, explains Mark. “You scrape the finished part off when finished,” he says. “The platform lasts for roughly 100 prints, then gets replaced.” Unique to the Mark One is the use of a high-precision “kinematic coupling” to precisely level and fix the build platform. Used in silicon wafer processing, the coupling precisely constrains all six degrees of freedom so that the build stage can simply be “clicked” into place. Set-to-reset leveling is reportedly repeatable to within 10 microns.

Strong first steps

“For us, using carbon fiber and nylon together makes so much sense,” asserts Mark. “If you’re printing with the common materials such as nylon, being able to incorporate continuous fibers enables an entirely new class of parts.” He adds that the Mark One can produce parts that are stronger than 6061 T6 aluminum, and, based on mechanical testing, provide good impact resistance.

He cites the part shown at the SolidWorks conference, a baseplate for attaching a race car wing to a car. Essentially a sandwich panel, the part has outer skin layers of neat polyamide for a good wear surface, while inside are three, 200-micron thick layers of carbon fiber laid around the outer edge, and a printed nylon honeycomb inside the carbon in the center of the part for increased strength to weight properties (see photo, at left). After the print is finished, the baseplate is ready to install (the print process creates the mounting holes), without the labor of layup or need for cure, and takes 6.5 hours of machine time to print, compared to perhaps a day for conventional infusion processing. “There’s no labor, cutting, gluing, trimming, molds or fixtures,” Mark points out. “The baseplate supports a wing that is capable of producing 860 lb/391 kg of downforce when the race car is traveling at 200 miles per hour,” a sizeable load condition to entrust to a 3-D printed part.

Like any advocate of carbon fiber composites, Mark faces questions from potential customers about cost. “Yes, carbon fiber is an expensive material,” Mark admits, but cautions interested parties to put that fact in perspective. “In the end,” he points out, “the difference between an all-nylon wing baseplate and a carbon fiber/nylon baseplate is $10.” And his process is not subject to factors that contribute to part cost in conventional composites processes. “With this technology, there’s no waste, no mold cost, no layup labor cost, and when you’re finished, you have a net-shape part!”

MarkForged isn’t just talking, it is producing desktop-sized Mark One machines, beginning at $4,999, for customer shipment in the coming months.

“We are actually a ‘2.5D’ system right now,” he quips. You’re putting down flat layers, and stacking them, but you’re not able to follow a trajectory or a contoured surface.” Aerospace companies, for example, will want more dimensions, and larger part sizes. Mark asserts that printing much larger structures is on the company’s “road map” and envisions the ability to produce an entire auto chassis or unmanned aerial vehicle (UAV). “We will be able to address those demands, as well as more complex load cases,” he predicts. Toward that end, MarkForged will offer more axes, via robotic handling, and larger build boxes, and its proprietary build heads will be able to handle the larger parts.

Future directions

Ultimately, Mark is motivated to bring down not only the cost of composite part fabrication but of its development as well. If a car frame were developed using AM, he suggests, “it could be a functional prototype within a week.” And the design could be tested, tweaked, then reprinted again, within a few days. “This significantly compresses the design process and cuts cost,” he claims, noting that “if Boeing wanted to test a new UAV design, they could conceivably come up with a working test vehicle in a week.”

Mark reports interest from prosthetics and medical device manufacturers, who could quickly custom-print a medical implant or components for an artificial limb to fit an individual. To minimize cost during the fitting process, he explains, “You can first print in plastic until the shape is matched, then print with fiber reinforcement to produce the high-strength finished part.”

Related Content

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreRead Next

Direct manufacturing of military aircraft parts

Laser sintering process shortens lead time, simplifies production of complex, high-performance parts.

Read MoreThe rise of rapid manufacturing

An outgrowth of rapid prototyping, tool-free additive fabrication technologies have the potential to form small, limited-run composite parts directly from CAD data.

Read MoreAdditive manufacturing a new frontier for composites

Leading additive manufacturing authority Terry Wohlers (Wohlers Associates Inc., Ft. Collins., Colo.) comments on two decades of AM progress and AM's prospects as a composites manufacturing solution.

Read More