Digital twin-enabled, award-winning SMC knuckle

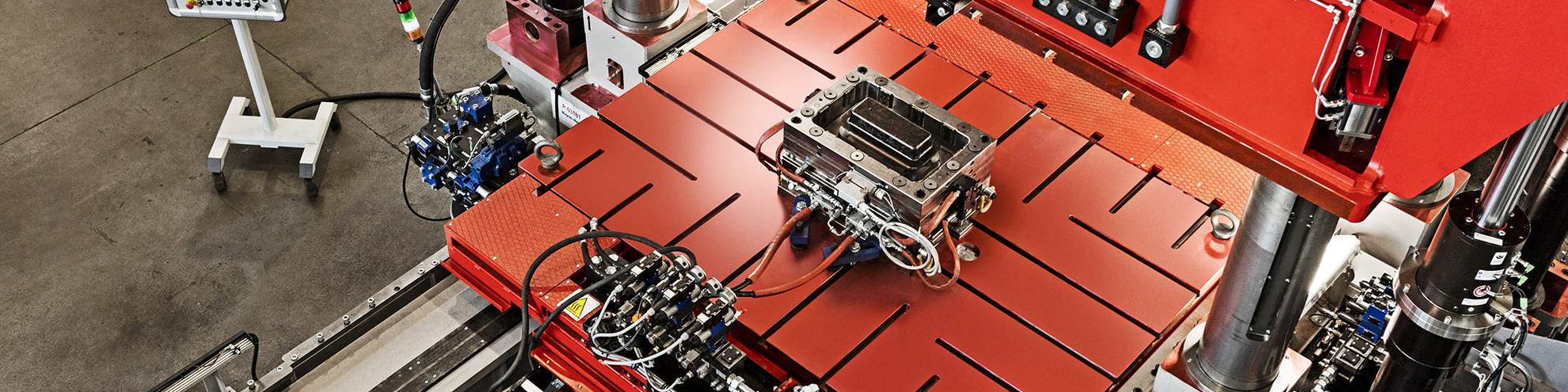

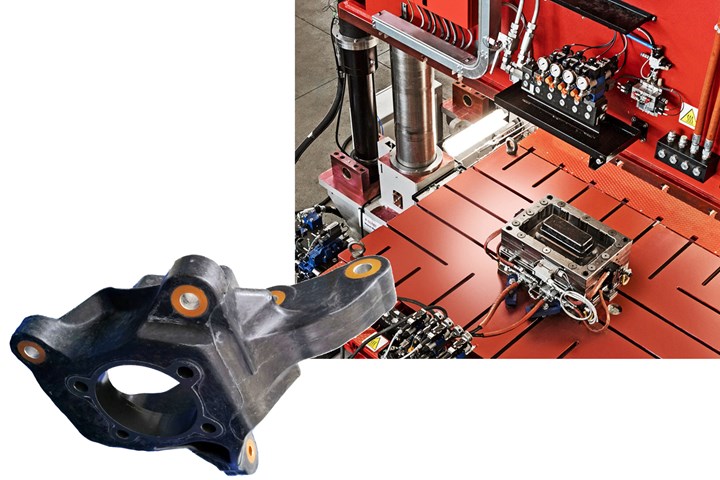

Marelli Ride Dynamics used its SMC digital twin to design this suspension knuckle, which saves 25% mass versus aluminum and won the 2020 Enlighten Award. It is manufactured on the same 1,500-ton SMC press used for digital twin test specimens. Photo Credit all images: Marelli Ride Dynamics

As part of the transition to electric powertrains, leading automotive suppliers are replacing metal with sheet molding compound (SMC) to achieve light weight and sustainability. A prerequisite is the capability to provide reliable and accurate performance prediction for these structural and safety-critical parts.

Marelli’s Ride Dynamics division (with main base in Turin, Italy) manufactures suspension components (such as subframes, knuckles and control arms) up to complete axles, wheel assemblies and frame semicorners in eight countries. Its Advanced Materials division has applied thermoset and thermoplastic composites in commercial parts using braiding, resin transfer molding (RTM), injection molding, SMC, thermoforming and overmolding processes. In optimizing its SMC parts, Marelli Ride Dynamics has worked with Hexagon’s Manufacturing Intelligence division (Cobham, U.K.) and its Digimat software suite to develop an integrated approach that couples processing-induced microstructure with anisotropic material behavior to reliably predict as-manufactured product performance.

The goal for Marelli Ride Dynamics was to build a true digital twin for SMC materials that enables early-stage design optimization. This requires integrating SMC process simulation — results from the as-manufactured composite microstructure — with a high-fidelity material card that accurately captures SMC’s anisotropic behavior. The latter was created by Marelli Ride Dynamics via standard coupon testing and Digimat software, accounting for fiber orientation and fiber content. This integrated approach was validated on an omega-shaped beam demonstrator that included variable rib thickness, rounded corners and co-molded aluminum inserts. It was made using Marelli Ride Dynamics’ 1,500-ton SMC press in Turin.

Physical test results were compared to digital twin simulation results and also with standard isotropic simulations. The Digimat-coupled multiscale structural analysis reduced prediction error ( >25% stiffness error for isotropic simulation down to 8% and free modal frequency response error of 20% down to 3%) and accurately predicted initial failure location with corresponding failure load.

ICME for SMC

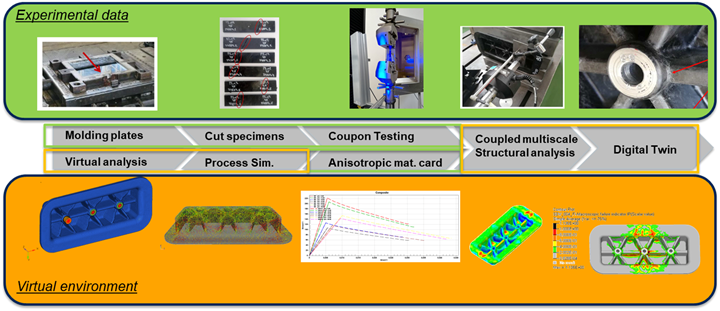

For this application, Marelli Ride Dynamics adapted the Integrated Computational Materials Engineering (ICME) approach (see “How to validate 3D printed composite part performance”) using Digimat into the following product development workflow: (1) material testing; (2) process simulation and microstructures; (3) coupled, structural FEA and (4) validation. “This allowed us to develop a dedicated simulation chain to capture and predict the performance SMC parts,” explains Salvatore Sottile, Advanced Materials applications engineer for Marelli Ride Dynamics. For more details, watch the Hexagon-Marelli webinar on this development.

Digital twin roadmap. Marelli Ride Dynamics completed both physical and virtual testing on specimens from flat plates and demonstrator omega beams as it worked to develop a reliable SMC material digital twin.

Material testing

Marelli Ride Dynamics manufactured plates for test coupons using four SMC charge patterns with different orientations, as well as plates with charge weld lines, and performed in-house tests including tensile, bending, interlaminar shear strength (ILSS) and puncture. With this material database, the company began modeling the SMC material card using the microscale tool Digimat-MF.

“We started with a fiber and matrix card to match the density of the SMC we tested,” says Sottile. “We then assumed a fiber bundle shape to match the experimental stiffness we obtained from 0° and 90° specimens as well as ILSS models. We then integrated anisotropic material behavior. In the end, we developed a material card that matches in-plane and out-of-plane material behavior with physical test results.” The next step was to model progressive failure using Digimat-RP and integrate a multi-component 3D orthotropic failure indicator. “In this way, we have developed a Digimat SMC material card that can reproduce the anisotropic behavior of the material,” notes Sottile.

Process simulation, coupled FEA

Marelli Ride Dynamics next began process simulations to define the orientation tensor. “We performed testing to get the resulting orientation tensor from the process simulation for the specimen surface and through the thickness of the material,” explains Sottile. “We mapped this information onto the shape of the test specimen, according to its position on the plate.” Using Digimat-MAP for macroscale modeling, this information was then integrated to represent digitally all the physical tests performed.

“Coupled with the structural FEA [finite element analysis], we then compared the digital versus physical test results,” says Sottile. The resulting SMC material card is not perfect, he says, but it is a good start. For example, there is some tradeoff to achieve the best compromise for bending and puncture test results. The next step was to scale up this material card and integrate with process simulation at the component level. “This anisotropic approach with progressive failure model was then compared with coupled multiscale structural analysis,” says Sottile, “and finally, we had a digital twin.”

Validation

To validate this digital twin, Marelli Ride Dynamics manufactured an omega beam (420 x 200 x 75 milimeters) and defined the optimized process parameters such as charge pattern and placement, molding pressure and temperature. “We then obtained the fiber orientation tensor around the as-manufactured component,” says Sottile. “But could we rely on this fiber orientation tensor from the process simulation? We tried to answer this via testing. We cut specimens from the beams and tested them using CT [computed tomography] scans. We compared through-thickness fiber orientation tensors from these results with our numerical results and found overall they were quite aligned. We then did bench tests on the omega beam parts and compared these with free modal analysis and stiffness analysis performed using classical isotropic composites analysis with knock-down factors, and with our new coupled multiscale analysis using Digimat and process simulation.”

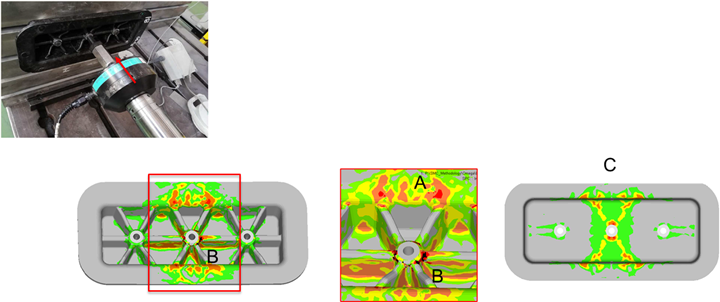

Validation of failure locations and load. The experimental bench test setup (left) applied a static load to the demonstrator omega beams, reaching a limiting stress at 76 kilonewtons. The isotropic composites analysis predicted a limiting stress at 80 kilonewtons but with no indication of failure, while the SMC digital twin accurately predicted initial failure at locations A, B and C at a reactive load of 82 kilonewtons, which was 7% higher than the experimental test.

The validation results for part stiffness showed a simulation error of >25% for the isotropic simulations. “These numbers are insufficient for design optimization,” says Sottile. The digital twin integrating the SMC process simulation with the Digimat structural analysis, however, achieved a predicted stiffness error of 8%. In static loading experiments, the digital twin approach accurately predicted the initial failure location and corresponding failure load within 7% of the experimental value — the numerical reactive load was 82 kilonewtons compared to the bench test value of 76 kilonewtons. In a free modal analysis, the predicted frequency response error was reduced from 20% for the isotropic simulations to 3% using the digital twin analysis.

Digital twin, award-winning parts

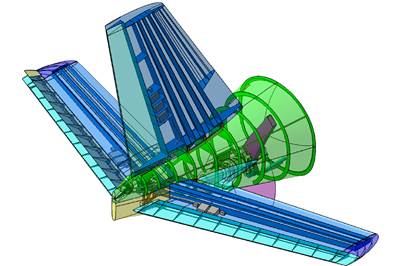

Marelli Ride Dynamics used its SMC material digital twin to design a suspension knuckle that reduces mass by 25% compared to a conventional aluminum knuckle. Recognized with the 2020 Enlighten Award in the “Future of Lightweighting” category, the newly developed advanced SMC (ASMC) steering knuckle is manufactured in Turin and showcases the ICME methodology and its ability to integrate process constraints very early in the design process. “Through extensive testing and analysis, our team has proven that significant mass savings can be realized without compromising cost, performance or volume targets,” says Antonio Ferrara, president of Marelli Ride Dynamics. “This award is further validation that the combination of lightweight materials with high-volume advanced manufacturing methods can disrupt the industry.”

“We have developed a competitive engineering approach into our product development workflow with composite materials,” says Sottile. “As a result, we can better exploit the anisotropic mechanical performance of composite materials, avoid over-engineered parts and better optimize our use of SMC materials to reduce cost. Moreover, it allows us to integrate process-induced constraints very early in design, optimizing performance while reducing our development timeline and cost.”

About the Author

Salvatore Sottile

Salvatore Sottile is an applications engineer and project leader in the Advanced Materials division of Marelli Ride Dynamics (Turin, Italy). He majored in mechanical engineering at Polytechnic of Torino, joined Marelli in 2017 and completed, with academic supervision from Polytechnic of Torino and Marelli as industrial partner, a Level II Specialized Master’s Degree in “New processes and technologies for hybrid materials finalized to automotive applications.” His main activities at Marelli involve leading metal replacement projects with composite materials in structural components.

Related Content

Nine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

Multi-flange RTM frames enable radical rear fuselage design

The Clean Sky 2 Advanced Rear End (ARE) demonstrator combines patented new frame design, thermoset and thermoplastic composites and smart tooling to advance aircraft design and cut weight, cost and production time.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More