A fascinating inside look at a marine design – three decades ago

Fabricated by Gougeon Manufacturing in 1990, Incognito is a composite catamaran that’s still setting speed records and besting much newer craft.

Gougeon Brothers Inc. (Bay City, MI, US) recently sent an interesting press release about a 28-year old catamaran that’s still setting speed records and besting much newer craft. Incognito is a composite catamaran that was fabricated by Gougeon Manufacturing in 1990. Russell Brown of Port Townsend, WA raced the 28-year-old vessel, a G32, single-handedly in the grueling R2AK (Race to Alaska). In the qualifying leg from Port Townsend WA to Victoria, BC he finished 40 minutes ahead of the rest of the fleet. He then led the race for three days and was the first solo finisher for the second year in a row, knocking more than 24 hours off his record-breaking 2017 win, aboard the same boat.

So I was surprised to find on the Gougeon web site a long and detailed development, design and construction document (last update: 1996) describing the painstaking process that Meade and Jan Gougeon carried out to make that fast G32 catamaran, which likely accounts for its success 28 years on. I’ve borrowed sections, below, and you can read the document in its entirety here: http://www.gougeon.com/prosetepoxy/G-32/welcome.html .

“When we decided to re-open our wind blade manufacturing plant in 1990, which had been idle for three years due to the wind industry's dramatic 1986 crash, we accepted that the wind industry was still a long way from regaining its former health. We needed to share plant overhead with a second product until the wind business returned to former levels. In addition to wind blades, we began manufacturing a unique, trailerable 32' long catamaran called the ‘G-32.’ My brother, Jan, and I had long thought there would be a large market for a lightweight catamaran that was fast, fun to sail, had weekend accommodations for 2 or 3 and was priced below $35,000. We had no intention of achieving large production; if we could arrange to build two per week we could accomplish our financial goals, three per week would be profitable.”

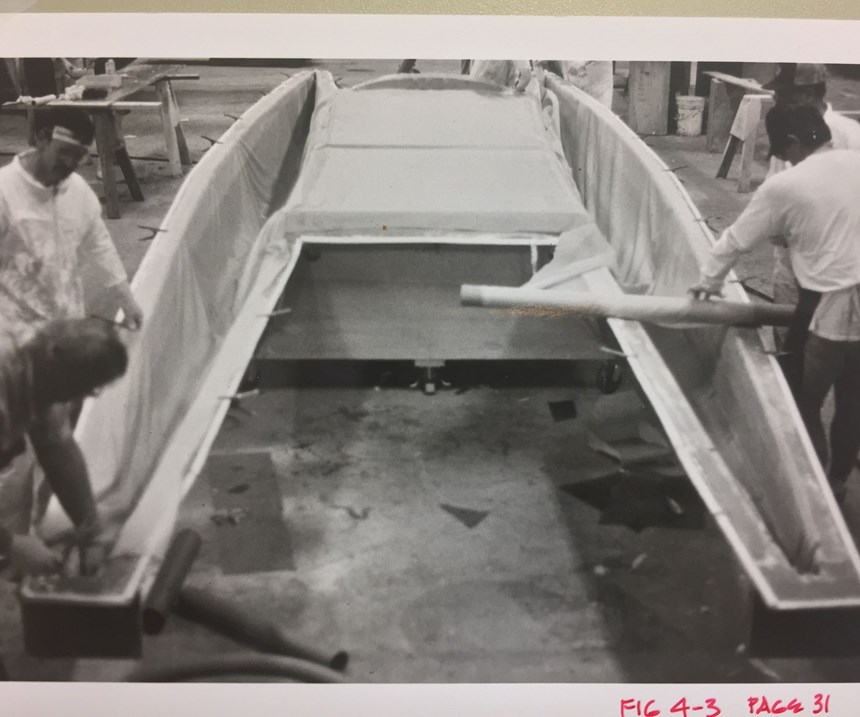

“The G-32 was designed so that the entire structure could be built in two large molds, an upper and lower, that were to be joined at the centerline in one large bonding operation. This allowed a minimal investment in tooling and molds, making low-volume production financially feasible. The single biggest design challenge was to build the G-32 light enough to be towed by a mid-sized car. To achieve this, the combined weight of the boat and trailer could not exceed 2,200 lbs. Our approach to this problem focused on two areas; first, we designed out of the boat as much unnecessary weight as possible. We kept surface area to a minimum and carefully designed the structure to accommodate anticipated loads. For instance, the cabin served as a large torque box to give necessary torsion resistance between the two hulls. Second, we used the lightest weight construction technology we could afford within our cost goals. We could spend no more than $10/lb. for molded shells, and these could not weigh more than 800 lbs. total.

“We have had many years of experience building high-tech, ‘one-off’ racing sailboats where exotic fibers, expensive core materials and epoxy resins were used to create very light but expensive boats. The molded parts of these custom boats could easily cost $50 to $100 per lb. Typically these high-tech boats were laminated over male molds requiring multiple vacuum bag applications to achieve a lightweight compacted laminate. Three separate vacuum bag applications were a minimum, with the two skins and the separating core all requiring separate compaction to assure a quality laminate. Boats using prepreg materials, such as the recent America's Cup yacht, might require 6 to 10 vacuum bag applications to debulk each layer, and then a final compaction of all layers before an oven-controlled cure can take place. The making and application of vacuum bags is labor intensive, and this has restricted their use in production boat building where female molds are always used. In the past, attempts to vacuum bag cores into hand-laid outer skins in female molds has caused excessive print-through, further reducing interest among builders.”

The Gougeon brothers go on to say that despite these issues, vacuum bagging and infusion was a must to save laminate weight. So, to save both weight and cost, they chose a new manufacturing method for the time, with the following steps:

1) Epoxy resin, formulated with a longer out-time, would be used for maximum properties, with the out-time enabling only one vacuum step, with the entire laminate compacted at once.

2) A polyester-based gelcoat in female molds would give a low-cost yet finished surface with a minimum of print-through. The authors note that they solved the significant problem of bonding the polyester gelcoat surface and the epoxy laminate with a specially-developed tie-coat substance, applied between the two dissimilar materials during the manufacturing process.

3) All reinforcing materials would be wet out mechanically with a roll-coater machine to reduce labor and achieve better resin control.

4) The specially-designed long open time epoxy resin would be post-cured at temperatures not exceeding 140°F to achieve high physical properties.

The two brothers carefully evaluated reinforcing materials to make the best laminate, when considering cost, panel performance, labor to assemble and finished outer surface quality. A matrix of 30 combinations were initially evaluated (you can see the table here: http://www.gougeon.com/prosetepoxy/G-32/goufig1.htm ) with a focus on stitched E-glass. Core was carefully evaluated, in several thicknesses and materials, as it was the most expensive component. The PRO-SET epoxy resin system, with an open time of 4 hours, was developed in Gougeon’s own labs expressly for use with this new manufacturing process.

The two brothers ultimately constructed 30 test panels using the materials in the matrix, then narrowed those to 12 material combinations, for fatigue testing on the company’s Hydromat test stand. Their key question was: “How much stiffness was necessary for the boat to perform properly in the most highly strained operating conditions?” The two say that based on the test results design changes were made to reduce flat areas in the boat’s design, given that those flat areas required additional stiffness, so that a less stiff, lower cost panel might be used.

“We determined that long-term panel resistance to sustained cyclic fatigue loads of 5 psi and intermittent slamming loads approaching 15 psi were necessary for long term survival of the G-32 structure. This criterion was not established in any scientific way, such as actual measurement with strain gauges (which is difficult to do). It instead reflected our experience with the performance of several material combinations used to build numerous watercraft with various success and failure over the years. This is the typical, historical, trial-and-error approach to boat design and engineering, which has not served the industry well since the recent revolutionary development of composite materials. New testing methods, such as the Hydromat, are an attempt to better evaluate composite materials performance in a way that closely simulates actual load conditions, so that more informed decisions can be made.”

The document goes on to describe in detail the short-cycle fatigue testing process. The material combination ultimately chosen, say the authors, “was not the strongest panel evaluated in any of the structural areas of stiffness, ultimate strength, or fatigue. It was, however, more than adequate to support the structural needs of the G-32 boat project. Of more importance, panel #48 scored well in three other areas; cost, weight, and ease of manufacturing.” Panel #48 consisted of multiaxial fiberglass skins from Brunswick Technologies Inc. over a Klegecell PVC foam core from DIAB.

Interestingly, one of the most difficult parts of the project, they say, was achieving the high-gloss exterior finish, without the excessive weight that gel coats can add. The solution was to have a highly trained individual doing the best gelcoat application possible, say the Gougeon brothers.

Despite the care taken in the design and material selection, the cost goal of $10 per lb. of finished laminate was not quite achieved, because in late 1992, the brothers decided to sell the wind energy division, which eliminated the main reason for the boat project. Production shut down shortly thereafter, after fabrication of only 14 G-32s. But, they say, epoxy-based boat construction technology developed with the G-32 is now widely used in the construction of high-performance boats, built in female molds. Meade and Jan Gougeon believe that their fabrication process did dramatically reduce the cost of manufacturing epoxy-based boats, compared to the cost of building custom boats on male molds. Plus, it eliminated styrene, and provided greater control over open time and cure rates. They conclude, “…the 14 G-32s that were built have performed as expected, with no structural failures of any kind. A bonus is that their light weight, combined with long slim hulls, has made for exceedingly fast boats that have won many races.” And, 28 years on, they continue to win!

Related Content

SmartValves offer improvements over traditional vacuum bag ports

Developed to resolve tilting and close-off issues, SmartValves eliminate cutting through vacuum bags while offering reduced process time and maintenance.

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More