A350 & A400M wing spars: A study in contrasts

In three short years, GKN Aerospace has taken its wing spar manufacturing strategies to new heights by dramatically reducing part weight, process complexity and production-cycle duration.

The GKN Aerospace (Filton, U.K.) factory in the Western Approach of the U.K. is dedicated to wing spar manufacturing. It produces the front and rear spars for the Airbus A400M military cargo transport and the rear spar for the Airbus A350. HPC covered A400M spar manufacturing in 2006, when it was produced at GKN’s site on the Isle of Wight, U.K. (Read more about the A400M spar manufacturing process in “Composite wing spars carry the western world’s biggest turboprop engines," under "Editor's Picks," at top right). Since then, A400M spar production has been transferred to the new dedicated spar facility in Western Approach (see far right photo, p. 27) to take advantage of synergies with the A350 spar operation and benefit from close proximity to the Airbus wing design center in Filton. As the first flight of the A350 drew near this year, HPC visited the facility to get an update on GKN’s process for the A350 spar.

The A400M and A350 spars: Different by design

Wing spars can be thought of as simple tapered C-shaped channels that make up the front and rear of the wingbox. But this is an oversimplification, because it ignores the hidden complexities of the wing design. First, there is the shape of the wing, dictated by aerodynamic, structural and ground-clearance requirements. Close examination of the A350 spars reveals that the inner spar has a very significant curvature. This is because the A350 inner wing is formed into a curved gull-wing shape. By contrast, the A400M’s wing is virtually straight, making the spar a simpler shape to manufacture (see photos, at left).

The structural issues add further complexity to the spar layup, due to the very high load inputs that occur at various points along the length of the spar. Attachments points for the engines, main landing gear (on the A350 only, because the A400M has a fuselage-mounted main undercarriage), flaps and other control surfaces require localized increases in laminate thickness at the attachment points. In other attachment areas, sacrificial woven carbon is added under attachment points or, if the attached component is aluminum, a layer of woven glass is added.

The length of the A350 spar is considerably longer, at 34m/111.5 ft, than the A400M spar, which measures only 19m/62.3 ft long. Further, the A400M spar is made in two sections, but the A350 spar is made in three.

The manufacturing strategies for each spar also differ, for several reasons:

- There were five years between the launch of the two programs; during that period the automation of prepreg layup by automated fiber placement (AFP) made major progress.

- The customer changed the material specification from a conventional toughened epoxy to the latest-generation interlayer toughened epoxy.

- The shape of the A350 spar is much more complex.

- A more optimized design was desired in the A350 spar; weight savings in commercial applications is now a greater priority in a time period in which fuel savings have grown in importance.

ATL vs. AFP

The manufacturing processes for the spars reflect their differences. The A400M spar is made by automatic tape laying (ATL) of carbon fiber over a flat tool (see bottom photo, this page). The ATL is supplied by MTorres (Torres de Elorz, Navarra, Spain). This flat pack of unidirectional material is then hot-drape formed (see photo, p. 30) to the final shape over a male tool. Then, the shaped laminate is transferred to a female Invar tool for final cure. By contrast, the A350 spars are built up in one step by AFP on a rotating mandrel, yielding two parts (port and starboard spars) in their net shapes at the same time (see opening photo, at left).

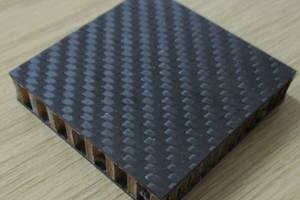

The A400M spar is made from Cytec (Tempe, Ariz., and Wrexham, U.K.) 977-2 carbon fiber prepreg, a material commonly used in military aircraft. The A350 spar is made from Hexcel (Stamford, Conn.) M21E/IMA, a much tougher prepreg system than older materials. The greater toughness is the result of a prepreg manufacturing technique that concentrates the toughening agents between the plies, rather than uniformly distributing them throughout the matrix. Notably, this material is the standard prepreg for all structural parts on the A350.

Given the increased complexity of the spars’ geometry and the drape-forming difficulties presented by this new generation of prepregs, GKN concluded that AFP was the lowest-risk option. This decision was made all the more easy by the continuing improvement in AFP laydown rates and the ability of AFP to optimize the structure by using a more complex ply layup than can be achieved with ATL.

The A350 spar: Layup and molding

Although the most obvious production improvements are seen in the layup and tooling of the A350 spar moldings, much of the novel production engineering has been applied to the machining and assembly processes.

The A350’s C-section spar’s three segments average 11.5m/37.7 ft in length, with a thickness of 25 mm/0.08 ft at the root end, which tapers to just 5 mm/0.020 inch at the wing tip of the outermost segment. Their size and weight is difficult to convey in words and dimensions. To put it in perspective, the average person could lift one end of the outer spar.

The A350 spar is layed up on CFRP mandrels placed in an AFP machine, also supplied by MTorres. GKN intends to have five of the machines in production; three have been delivered (at €5 million/$6.76 million each), and two more are on order. As noted, two spars are layed up simultaneously. One might have expected material at 90° and 45° to have been placed continuously around the mandrel, from one spar onto the adjacent spar. However, GKN takes advantage of the machine’s ability to cut and restart each tow independently. Thus, the spars are built up separately, with a small gap between them. This eliminates a cutting step, minimizes material waste, affords greater design freedom, yields a more fully optimized ply layout and reduces the weight of the spar.

The hollow carbon fiber mandrels were designed and manufactured, and the materials were supplied, by Umeco (Heanor, Derbyshire, U.K.) — now part of Cytec Industries and doing business as Cytec Industrial Inc., a division of Cytec Engineered Materials Inc. (Tempe, Ariz.). Stiffness was a major challenge, with a requirement of 0.5 mm/0.020 inch or less deflection under a load of 150 kg/331 lb. At the same time, weight targets had to be met; for the inner mandrel, the weight is 4 metric tonnes (8,818 lb). The machine limit was 5 metric tonnes (11,023 lb), due to inertia issues related to the mandrel’s rotation speed, which varies depending on whether it is laying a flat area, going around a corner or cutting a ply. To accelerate and decelerate, the machine has to fight the inertia of the mandrel, which is governed by the weight and the shape — the latter being fixed by the design of the wing. Thus the weight and the stiffness requirements drove the mandrel design to CFRP.

A big improvement in processing time has been achieved by reducing the number of consolidation cycles required when laying up the innermost spar. In April 2011, consolidation required many cycles. During each cycle, the mandrel and partial layup temperature was elevated using a large (about 13m by 1m/42.7 ft by 3.28 ft) bank of infrared heaters. Then a cylindrical vacuum bag, stored at the end of the mandrel, was pulled over the laminate and vacuum was applied. This was necessary, at the time, to deliver the low void content demanded by Airbus. But today that repetitive procedure has been displaced by a single, room-temperature vacuum consolidation after the entire laminate is layed up.

The finished laminate is transferred from the mandrel to a female Invar tool for curing, using vacuum lifting equipment. The A350 spar is cured in one of two autoclaves, both 16m by 3.5m (52.5 ft by 11.5 ft), with a standard cycle time of 10 hours, including ramps. This cycle time is used on all spars because the difference between the spars, in terms of mass, is insignificant compared to the tool’s thermal mass. Two spars are cured at the same time, except for the inner spar, which is done on its own. Two autoclaves meet the needs for the production rate, assuming a 30-minute load and unload at the beginning and end of each cycle.

The molded spars are machined in a double-headed tool provided by Flow International (Kent, Wash.). A waterjet is used to cut the spar profiles, and a conventional machining head (24,000 rpm) is used to reduce thickness in critical areas. For example, there is a ±0.25 mm (±0.010 inch) tolerance on the spar height. To avoid cutting structural fibers, sacrificial woven carbon fiber is added in a separate, manual operation, using laser ply positioning to ensure accuracy. Then the area is machined to tolerance. Sacrificial layers are bonded with colored film adhesive so technicians can see if the structural plies are cut. Woven glass, instead of carbon, is used where aluminum fittings will be attached.

Finally, the spars are subjected to nondestructive inspection (NDI) using an ultrasonic machine of the latest phased-array type, from GE Inspection Technologies LP (Lewistown, Pa.). The device reportedly spots defects down to 6 mm2 (0.009 in2) in 20 percent of the time taken by conventional NDI technologies. (See also “Nondestructive testing: Better faster and cheaper," under "Editor's Picks," at top right.)

Drilling and assembly

Beyond spar manufacture, GKN also performs a large number of assembly operations. First, a small number of brackets are manually installed in the inside of each spar. This facilitates mounting the spar onto a fixture to transport it around the automated assembly workshop. The spar, with its fixture, is moved on a manually guided vehicle (MGV) to the first station of the assembly process.

Inner spars, which are thicker and have heavy metallic attachments for the undercarriage and flaps, are first taken to a large 5-axis machining center that drills holes through the composite parts and the metallic fittings. From there, the holding fixture and inner spar are transported to a station where fasteners are fitted. The middle and outer spars, which are thinner and have lighter fittings, also are taken to a robotic station where all the holes are drilled. Altogether, on a set of six spars required for one aircraft, a total of 16,000 holes are drilled. (See photo of robot with drilling head, at left.) Then the fixture and spar are moved to a second robotic station that applies the fasteners after all the fittings have been located in the fixture.

The three spar sections, still on their holding fixture but with all their attachments fixed, are finally brought together for joining, using the data points on their fixtures. The joints feature flat, butterfly-shaped CFRP plates on the outside and inside of the web, plus angled plates that join the inside of the flanges and radius.

However, the surfaces that will be bolted together do not align perfectly, due to slight variability in spar thickness, which is due, in turn, to variations in prepreg material thickness and slit tape width. The solution is to measure these surfaces using photogrammetric equipment supplied by Steinbichler Optotechnik GmbH (Neubeuern, Germany). An optical device, held in the hand of a robot, collects data that is sent to a machining center, supplied by HG Grimme SysTech GmbH (Wiedergeltingen, Germany), which is located adjacent to the joining fixture. In the machining center, the plates are modified to ensure that any offset in the surfaces to be joined is produced in a mirror image on the surface of the joining plate. The custom plates are then used to join the spar’s three sections.

After they are successfully secured, these joints are temporarily undone to make the spar easier to transport to an Airbus facility in Broughton, U.K., where the wing is assembled.

Related Content

PRF Composite Materials introduces primer, adhesive films

Novel RFA570 eXpress cure adhesive film and RF Primer are compatible with PRF’s full range of epoxy prepregs formulations.

Read MoreXlynX Materials BondLynx and PlastiLynx for low surface energy PP, PE substrates

Award-winning Xlynx materials use breakthrough “diazirine” technology to boost bond strength up to 950% as adhesives, primers and textile strengtheners.

Read MorePro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

Read MoreFilm adhesive enables high-temperature bonding

CAMX 2024: Aeroadhere FAE-350-1, Park Aerospace’s curing modified epoxy, offers high toughness with elevated temperature performance when used in primary and secondary aerospace structures.

Read MoreRead Next

Composite wing spars carry the enormous turboprop engines

Airbus A400M aircraft prompts new spar design and new manufacturing system designed to make it.

Read MoreNondestructive inspection: Better, faster and cheaper

Faced with new time and cost pressures, NDI system suppliers are integrating inspection with manufacturing to reduce its share in part cost and cycle time.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More