XlynX Materials BondLynx and PlastiLynx for low surface energy PP, PE substrates

Award-winning Xlynx materials use breakthrough “diazirine” technology to boost bond strength up to 950% as adhesives, primers and textile strengtheners.

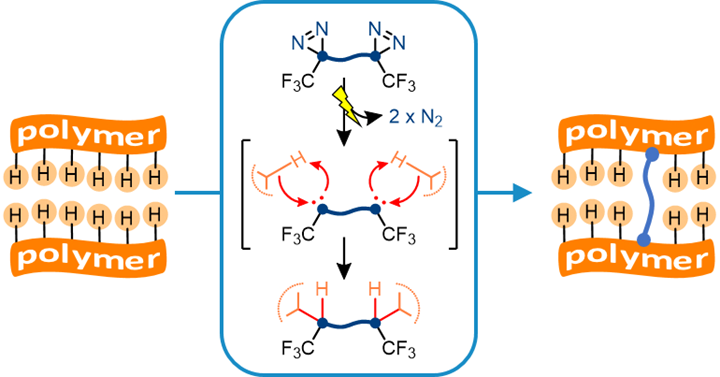

XlynX compound cross-linking process. Photo Credit, all images: XlynX

XlynX Materials (Victoria, Canada) has received a 2023 Innovation Award from the Adhesion and Sealants Council (ASC) for “Development of Universal Covalent Adhesives for Use with Low Surface Energy Polymers” (see “XlynX Materials releases new polymer molecular glue: BondLynx).

Low surface energy (LSE) polymers such as polyethylene (PE) and polypropylene (PP) are materials that are increasingly found at the forefront of technological innovation, from ropes and mechanical parts to performance textiles and medical devices. According to XlynX Materials, this is because LSE polymers are relatively cheap to produce, can be molded to specific dimensions and offer high strength, durability and resistance for such lightweight materials. However, these same qualities result in LSE polymers that are resistant to adhesion (gluing), layering, coating and dyeing applications, which limits how they are used.

In response to this challenge, XlynX Materials has developed a highly reactive suite of compounds that chemically insert themselves into unreactive polymer surfaces. In this way, they are reported to transform LSE polymers into materials that are no longer resistant to gluing, coating or other adhesion-based applications. This breakthrough “diazirine” technology enables abundant polymers to be used in a host of new applications.

According to Dr. Jeremy Wuff, lead inventor and scientific advisor for XlynX Materials, “We were first to develop a cross-linking molecular adhesive for this kind of use with commodity polymers, and we aim to remain a leader in this innovative field of diazirine chemistry.”

XlynX’s senior research scientist, Dr. Stefania Musolino receiving Innovation Award from Adhesion and Sealants Council (ASC) in New Orleans, Louisiana.

The new compounds, known as BondLynx and PlastiLynx, are easy to apply and are activated by either moderate heat or UV/Vis light. They are primarily designed as adhesives, primers and textile strengtheners. According to lap shear tests, the strength of bonds between LSE polymers — glued together with traditional, store-bought adhesives — have been increased by as much as 950% when first primed with XlynX’s compounds. Moreover, the company’s products have shown potential in new applications like organic electronics stabilization, quantum dot photopatterning and new composite material development.

Product samples for testing and research purposes are available. Please send requests to info@xlynxmaterials.com to consult with XlynX experts.

Related Content

-

Belzona composite wrap restores corroded carbon steel pipeline

Two-part epoxy paste, epoxy structural adhesive, composite wrap and anti-corrosion coating prevent environmental and economic loss for customer.

-

Pittsburgh engineers receive $259K DARPA award for mussel-inspired underwater adhesion

The proposed META GLUE takes inspiration from hydrogels, liquid crystal elastomers and mussels’ natural bioadhesives to develop highly architected synthetic systems.

-

BiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.