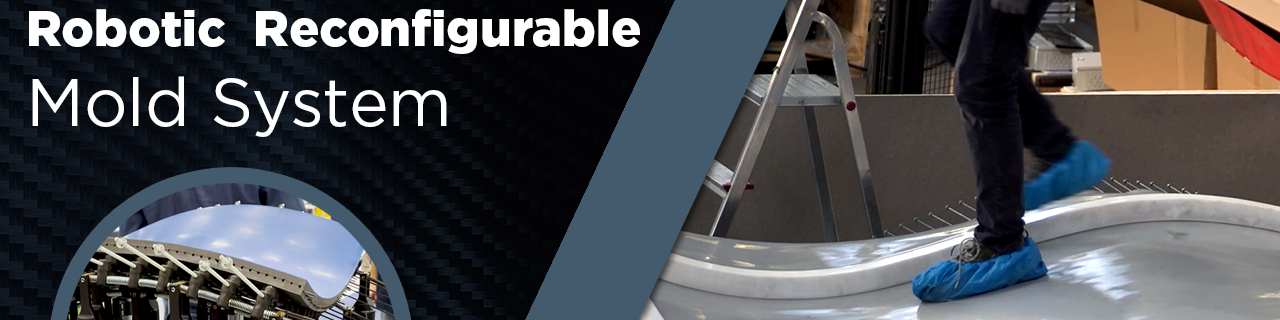

Adapa’s (Aalborg, Denmark) reusable, adaptive mold system replaces the time and waste of CNC machining and one-off mold production by using the composite part’s digital design file to actuate cylinders which form the system’s silicone membrane surface into curved shapes for molding composites, concrete and glass or thermoforming foam, thermoplastic laminates, etc

Related Content

-

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

-

CirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.