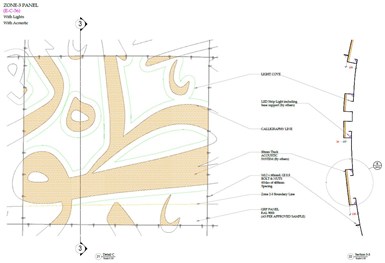

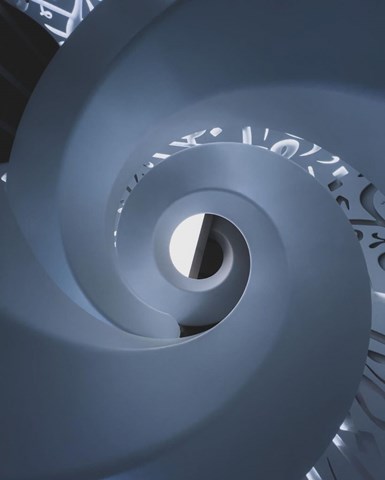

Advanced Fiberglass Industries (AFI, Dubai, United Arab Emirates) was founded in 1996. Featured in CW’s October 2022 article on the Museum of The Future (MOTF) interior lobby, AFI was responsible for construction and installation of its 7,700 square meters of composite panels, each with a different curved shape and set of Arabic calligraphy letters, many featuring acoustic insulation and inset with LED lights. AFI also supplied 356 composite panels as cladding for the lobby’s three spiral staircases — two intertwined in a DNA-like shape and one spanning the full seven stories of the MOTF — as well as 238 oval light structures made from composites for the parking decks.

As explained in the MOTF lobby article, one enabling technology for this project was AFI’s use of reconfigurable digital molds from Adapa (Aalborg, Denmark). In fact, AFI was the first company to use the Adapa system for molding glass fiber-reinforced polymer (GFRP) panels in the Middle East and implemented customizations that are now standard, such more magnets under the silicone membrane molding surface from rising during vacuum molding of composite panels and extra actuator rods underneath to smooth out the silicone membrane as it reconfigured into new shapes. “We had seen the Adapa mold system being used to produce glass fiber-reinforced concrete [GRC] panels for the Kuwait International Airport project,” says Chaudhry. “We thought it could provide a solution for us to meet the time and cost requirements for the hundreds of panels we’d need to make for the MOTF lobby.”

This innovation and willingness to look for unusual solutions, and then engineer them to work well, is part of AFI’s personality. Another example is the 7-meter-tall “Evolutes” sculpture on display in Dubai’s iconic Bourj Khalifa hotel (see p. 48 Post Cure column in CW’s Feb 2022 issue). Conceived by internationally-renowned designer Karim Rashid, it was actualized by AFI in CFRP, using biaxial fabric and clear epoxy resin with ground natural stones to create a uniquely intriguing, highly-reflective surface.

AFI’s 3,250-square-meter facility in Dubai includes a climate-controlled cleanroom, post-curing oven, paint booth, CNC three-axis router and KUKA (Augsburg, Germany) CNC seven-axis milling robot. The company is ISO 9001:2015 certified and employs roughly 100 people. Its composites expertise includes not only GFRP but carbon fiber composites (CFRP) as well, and a long history of projects in polyester, vinyl ester and epoxy resins using hand layup, resin infusion, resin transfer molding (RTM) and Light RTM (LRTM). It also excels in using aerospace core materials, including honeycombs and foam, and vacuum bagging for lightweight panels and veneers with tight tolerances.

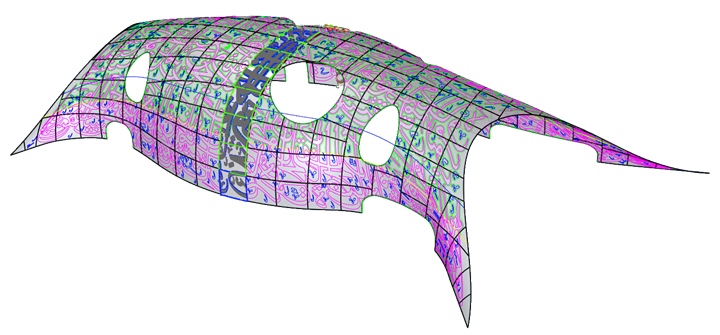

Shown as a complete surface above, each of the 228 composite cladding panels for the Museum of the Future lobby was unique. AFI created a digital model for each, which then had to be fabricated and, upon installation, joined into a seamless surface.

AFI’s expertise in design and engineering, including use of AutoCAD, Solid Works and Rhino 3D software, is impressive, showcased especially in the complex requirements for the MOTF lobby (see CAD screenshot for the lobby’s complete cladding above), where the 228 panels varied in thickness, curvature and Arabic calligraphy “cutouts”, yet had to maintain a tolerance of ± 2 millimeters once joined, certified by a 3D scan of the completed installation.

“AFI has always pursued a wide range of projects,” explains Majid Akram Chaudhry, general manager of AFI, “but it basically segregates operations into three main specializations: military, automotive and architecture.” I would argue that a fourth segment includes marine vessels, structures for theme parks and various specialty constructions, including aesthetic carbon fiber parts for automotive and consumer applications, including furniture.

Military and automotive

AFI has manufactured more than 1,000 GFRP hoods for Dubai-based NIMR Automotive. “This is a 7-square-meter bonnet which is bigger than that for a HUMMER,” says Chaudhry. “We work with NIMR to design products such as doors, fenders, dashboards and consoles for military vehicles. We're also designing vehicles with Calidus (Dubai, UAE), which makes armored vehicles, and building parts for the vehicles. We recently built a complete vehicle for them, where they devised the roll cage system, and we designed all the body panels, including the doors, fenders and bumpers. The vehicle is designed to be really fast for a task force that can be driven at high speeds, even in extreme desert conditions. The idea was to have a strong engine and a very light body.”

AFI automotive projects include (top to bottom) the N360 supercar with Shaali Motorsports, the Ghiath smart partrol for Dubai police with W Motors and a customized redesign of a 1960s muscle car built for the 2022 Batman movie.

AFI has also designed and built parts for concept and small-series production cars, trucks and recreational vehicles. “We have made a customized composite camper that is towed behind a truck and a variant of the Corvette Stingray, designed from scratch and built for a Hollywood movie. We made all of the body panels using Gurit epoxy, wet hand layup and vacuum bagging. There was not one pinhole; the finish is amazing. That car will be at a new Warner Brothers theme park in Abu Dhabi.”

In 2021, it collaborated with W Motors (Dubai, UAE) to produce the complete set of body panels for the Ghiath smart patrol vehicle for Dubai police. “This is one of the most advanced security vehicles in the world,” says Chaudhry, “and the first W Motors car to be fully produced in the UAE. We also have a contract with W Motors to build the roofs and hoods for 10 custom vehicles. These are similar to the HyperSport supercar in the movie Fast & Furious 7.” Features of these military and automotive parts include reinforcement ribs and PVC foam core to add rigidity where needed and vacuum bagging for lightweight, as well as excellent surface finish, which includes AFI’s expertise in gelcoating and painting.

Architectural expertise

In architecture, the MOTF lobby has to be one of the most impressive projects ever completed in composites. “It was really only possible with composites,” says Chaudhry. The engineering work alone for this project was insanely complex, not to mention passing stringent fire resistance (FR) test requirements and meeting schedule and cost targets.

AFI architectural projects include (top to bottom) the 26-meter-diameter composite sphere atop the 15-story Ministry of Foreign Affairs building in Ashgabat and the dome atop the Center for Islamic Civilization, made from 392 composite arches and dome sections.

But AFI has a long history in meeting the demands of challenging exteriors and interiors. For example, AFI built the 26-meter diameter sphere, which houses a conference room, atop the 15-story Ministry of Foreign Affairs building in Ashgabat, Turkmenistan. It is made from more than 300 double-curved composite panels and decorated with a gelcoated map of the world.

AFI also constructed the 75-meter-high dome for the Center of Islamic Civilization in Tashkent, Uzbekistan. “This is one of that country’s most monumental projects,” says Chaudhry. “The building will hold one of the oldest copies of the Quran that exists. It was to be built from steel and concrete only, but the Minister of Construction had seen buildings using GFRP and was interested to use it.” The 26-meter-diameter dome comprises 392 separate components, made using hand layup and vacuum bagging with FR epoxy resin, glass fiber fabrics and PVC foam core. AFI built these arches and dome sections in its factory and then shipped them to the construction site, where it joined them together to provide a seamless finish over 7,000 square meters of surface, which was then decorated with mosaic tiles. “This architectural structure was viable due to the unique characteristics of composites,” says Chaudhry. “We were able to keep the weight of the panels very low, which enabled quick and easy installation on-site.”

AFI constructed the interior of the Switch restaurant, designed by Karim Rashid, using composites and the Adapa reconfigurable mold system for the ceiling panels.

Thanks to AFI’s precise construction and high level of finish, the MOTF lobby spiral stairs are a work of art.

Not all of AFI’s projects are that large. It has fabricated numerous smaller domes, spiral staircases and exterior claddings. In one of two additional projects completed with designer Karim Rashid, AFI again used the Adapa adaptive molding system to build curved ceiling panels for the interior of the restaurant, Switch, in Dubai (see above). “The Adapa system allows us to complete such projects quickly and cost-efficiently,” says Chaudry, “eliminating the cost of building plugs and molds. Creating bespoke interiors at an affordable cost has become one of our specialties. This includes not only unique shapes, which only composites can produce in an affordable way, but also aesthetic finishes, such as the chrome paint system imported from Italy for the Switch project.”

New technologies, future vision

“Our vision is to create a benchmark when it comes to the world of products built with composites,” says Chaudhry. “Our focus is to continue our leadership in advanced composites fabrication and delivering projects that exceed international standards and provide exceptional customer satisfaction.” AFI is also currently focused on growth.

AFI produced more than 30,000 composite food delivery boxes for companies like Talabat. Photo Credit: AFI (top) and Yousra Zaki for CatererMiddleEast.com (bottom).

“During the Covid pandemic, AFI manufactured more than 30,000 delivery boxes to cater to the demand for home delivery solutions,” says Chaudhry. It did this working with the online food ordering company, Talabat, and several other companies. “We have now expanded our operations into a second site (AFI 2), in the city of Umm al-Quwain [about 70 kilometers north of Dubai] and also in a third site, AFI 3, in the same Al Quoz neighborhood of Dubai as our headquarters. We will thus segregate our automotive, architecture and other custom products in these three facilities to better cater to requirements globally. We also plan to acquire new technologies, including a 3D printer capable of glass and carbon fiber-reinforced composites.”

“We are already working on some solution-based projects,” says AFI business director, Patrik Gajdosik, “where we hope to build something beautiful for the world to visit. We also aim, in the near future, to mass manufacture body panels for various vehicles for clients globally and to explore the aerospace market. We never say no to a challenge.”

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)