AIA 2014 Convention report

The ACMA helps American Institute of Architects launch Composites Pavilion at Chicago convention.

The American Institute of Architects (AIA, Washington, D.C.) has served as the voice and leading source of continuing education for the architecture profession since 1857. The AIA’s National Convention and Design Exposition is an annual opportunity for architectural suppliers to exhibit and educate attendees about their latest offerings. In years past, the AIA had created a number of pavilions in which suppliers of common construction materials — wood, metals, concrete, stone and tile — were gathered for the convenience of convention attendees. In 2013, the fact that purveyors of composite materials had no such on-floor identity was recognized and, this year, corrected with the help of the American Composites Manufacturers Assn. (ACMA, Arlington, Va.). ACMA took full advantage of the opportunity to sponsor the AIA’s first-ever Composites Pavilion at the institute’s 2014 convention, held June 26-28, in Chicago, Ill. Situated very close to the convention hall’s main entrance, the new pavilion was a fitting showcase for 24 participating ACMA members.

The creation of the Composites Pavilion signals that composites are finally staking ground in the architecture/building materials community. “The potential for composites in building and construction is huge,” contends Bill Kreysler, president of Kreysler & Associates Inc. (American Canyon, Calif.). His firm exhibited its new Fireshield 285 fiber-reinforced polymer (FRP) cladding system, which forms the façade of the new San Francisco Museum of Modern Art expansion. (More about the project can be found in by clicking on "Architectural composites: Rising ot new challenges" and/or "Composite foundation wall system unveiled at AIA convention" under "Editor's Picks," at top right). According to Kreysler, composites currently make up only 0.5 percent of all materials used in construction, “and yet, the construction market accounts for roughly half of the composite materials volume sold in the U.S. Imagine the impact if we could increase composites’ penetration to 1 percent.”

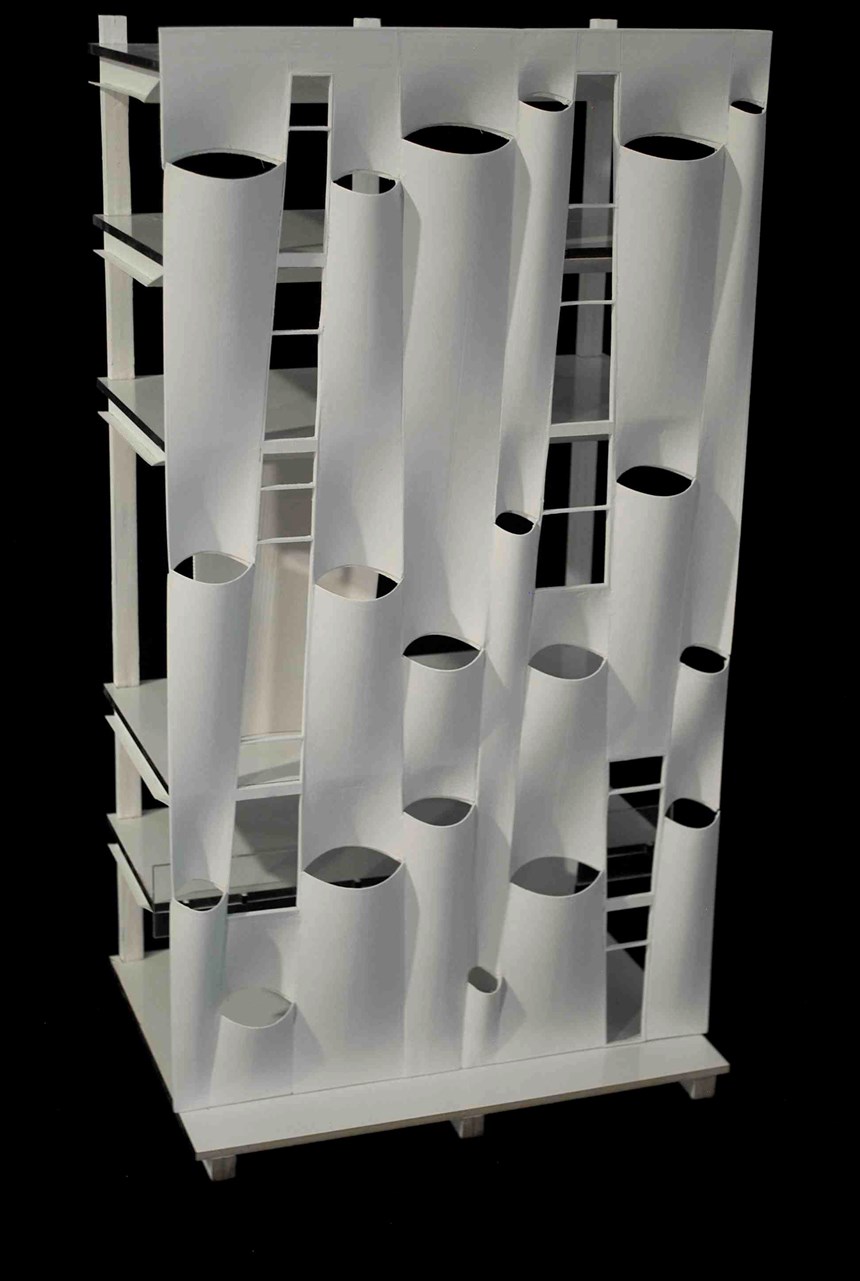

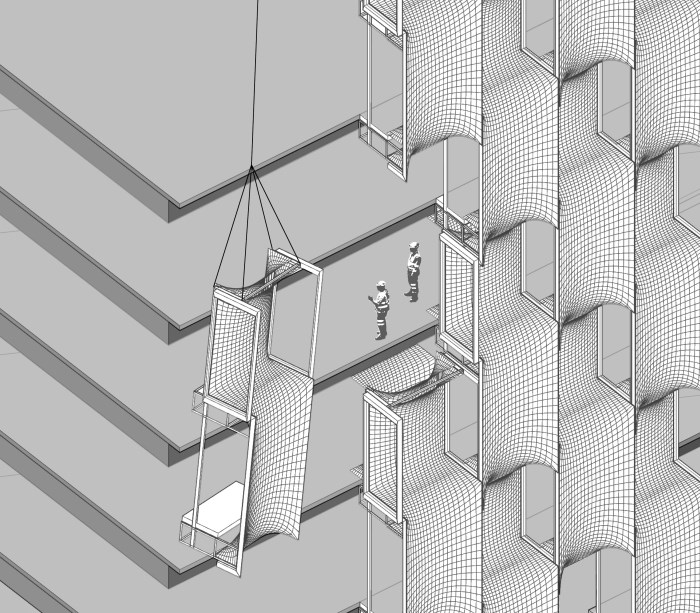

Kreysler & Associates also has funded research into the use of composites to integrate structural load-bearing capability, insulation and other functions into the building envelope (e.g., cladding/barrier wall products), saving time and money. Research results presented in an exhibit by California Polytechnic State University – San Luis Obispo (Cal Poly SLO) included the following projects:

• SINErgy fiber-reinforced polycarbonate as a primary material

in a barrier wall system.

• Emerging Web composite panel system embedded with

windows (via integrated mullions) and insulation, which

connect seamlessly to create a play between solid and void.

• Relaxed, a barrier wall system of large-scale, complex curved

FRP panels that supports standardized glazing modules and

creates new opportunities in usable niche spaces and lighting

within the facade itself.

Ashland, LLC (Columbus, Ohio) touted CompositeBuild.com, its Web-based and unbranded — that is, not associated with Ashland or its specific products — education resource aimed at connecting the building industry to composite materials. A variety of new materials and fabricated products also were on display within the pavilion, including Composite Panel Systems’ (CPS, Eagle River, Wis.) revolutionary EPITOME composite foundation walls (see photos at left and/or click on “Composites attract (more) attention as construction material,” under "Editor's Picks").

Kalwall (Manchester, N.H.) displayed its highly insulated, translucent wall and SKYROOF systems, fabricated flat or in curved configuration from structural sandwich panels made from glass fiber-reinforced faceskins, with fiberglass batts or aerogel for insulation. Kalwall products are used in the Carbon-Neutral Energy Solutions (C-NES) Laboratory at the Georgia Institute of Technology (Atlanta, Ga.) to reduce energy consumption. The lab’s north-facing wall, for example, features a 30-ft/9m high translucent façade of Kalwall and glass, which eliminates the need for artificial light during daylight hours.

GlasCurtain (Calgary, Alberta, Canada) exhibited what it called “the first new material in 50 years for curtain-wall framing systems.” By replacing aluminum framing with fiberglass composite framing, GlasCurtain products reportedly accrue more LEED v4 points than any other curtain-wall system. (LEED, short for Leadership in Energy and Environmental Design, is the Washington, D.C.-based U.S. Green Building Council’s program through which building projects can earn points toward “green” certification.) The GlasCurtain system reportedly is cost-competitive with other framing materials, reduces building energy loss and long-term operating costs, and improves durability.

Visitors to the pavilion’s Best Bath Systems (Caldwell, Idaho) booth heard about its ONE Bath System, which features a durable composite surface and modular wall combination that provides a quick, cost-effective but elegant design solution for upgrading bathrooms, for example, in mid-century institutional facilities, where other options are not feasible due to asbestos removal issues.

3A Composites (Sins, Switzerland, and Colfax, N.C.) unveiled its new BALECO balsa plywood products, for use as lightweight cores, while Technical Fibre Products Inc. (Schenectady, N.Y.) introduced its Tecnofire materials, designed to achieve highly effective passive fire protection with numerous cosmetic options as a replacement for unsightly sprayed intumescent systems. Applications include exposed steel structures.

Related Content

Composites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

Read MoreMicrowave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

Composites attract (more) attention as construction material

The American Institute of Architects (AIA) is hosting its annual show this week in Chicago, and composites are getting unprecedented attention there.

Read MoreArchitectural composites: Rising to new challenges

In North America, Europe, the Middle East and Down Under, architects and engineers are finding composites are a good fit in groundbreaking applications.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More