Audi R8 seat wall: A prelude to production

Audi takes it upon itself to design and develop carbon fiber composite structures that, the company hopes, will enter high-rate production.

Share

Read Next

High-volume, high-rate automotive manufacturing has been, for many years, the Holy Grail of the composites industry. Today, autocomposites is arguably the second-most important target market for materials suppliers and parts manufacturers in the advanced composites segment, nearly on par with the aerospace industry. But putting composites on the same material palette as the auto industry’s still-preferred steel and aluminum will take time and effort. Those who would do so face formidable challenges: Composites’ complexity, the result of its combination of fiber with matrix and all that implies for its potential performance parameters, present inherent design and simulation difficulties. Composite materials, unlike steel and aluminum, have yet to be standardized. Then there are the relatively high costs and relatively long cycle times. Still, auto OEMs are highly motivated to take weight out of vehicles, and for that reason alone they are clearly willing to give composites a chance.

For automotive OEMs, the question is, Where do we start? One of the most popular and sensible strategies is to begin with a low-volume application and evolve to high-rate production. This is what Audi (Neckarsulm, Germany) had in mind about seven years ago, when development began on its Modular Sports-Car System (MSS), designed for use in the Audi R8 Coupe, R8 Spyder, R8 LMS (race car) and the Lamborghini Huracan — all two-seaters, with rear-mounted engines.

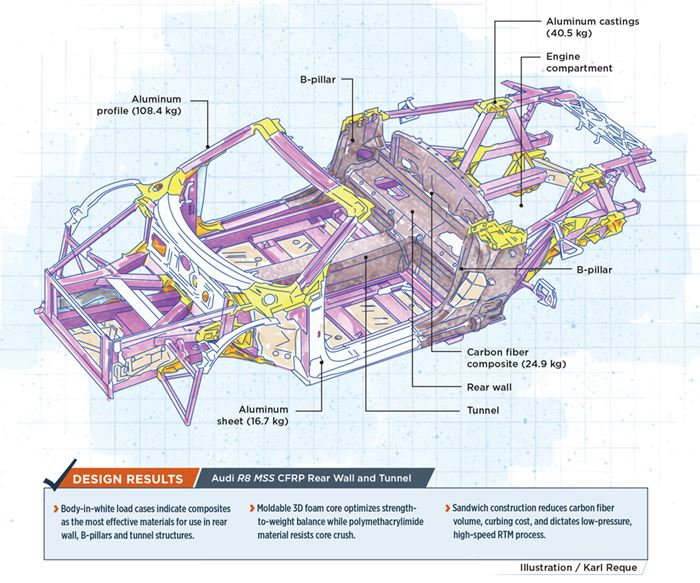

The MSS was envisioned as a tool for applying advanced materials to the body-in-white (BIW) to reduce mass and improve efficiency, particularly as vehicles evolved toward electrification. David Roquette, a technology development CFRP specialist at the Lightweight Design Center Audi (Neckarsulm), says the first-generation R8 was aluminum, but Audi decided the next generation of the MSS program’s applications should use carbon fiber composites. The question was where to apply it. This, says Roquette, launched a three-year BIW assessment effort to find an answer. He and his colleagues used an in-house-developed optimization software package to identify 23 load cases on the BIW, and then identified the BIW parts that experience the most anisotropic stresses, and, thus, were deemed best suited for composites.

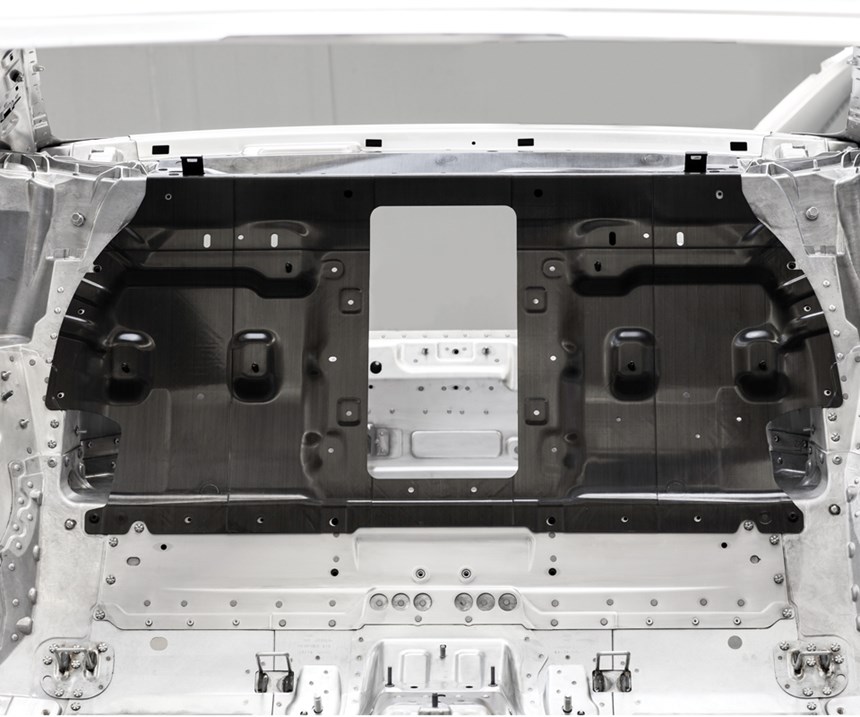

“However, it was not just stress,” Roquette notes, “but economic as well. Can we build it? Do we have the technologies? Does it make sense in terms of cost and weight?” The parts that met these criteria changed as development work evolved, but revolved around the driveshaft tunnel and the rear wall, which separates the passenger compartment from the rear engine compartment. Applying carbon fiber composites here on the 2016 R8 Spyder and Coupé, says Roquette, offered a substantial improvement in torsional stress and vehicle stiffness and a good opportunity to reduce vehicle weight.

Designing for load cases

Roquette’s colleague Felix Diebold, also a technical center CFRP specialist, says that when Audi’s composites research first focused on the previously mentioned 23 load cases, the company was looking particularly for opportunities where composites would enhance the BIW’s torsional stiffness and reduce weight, thereby boosting overall vehicle strength and passenger safety. Design engineering at Audi led to a layup comprising unidirectional and woven carbon fiber fabric reinforcements combined with a fast-cure epoxy resin system.

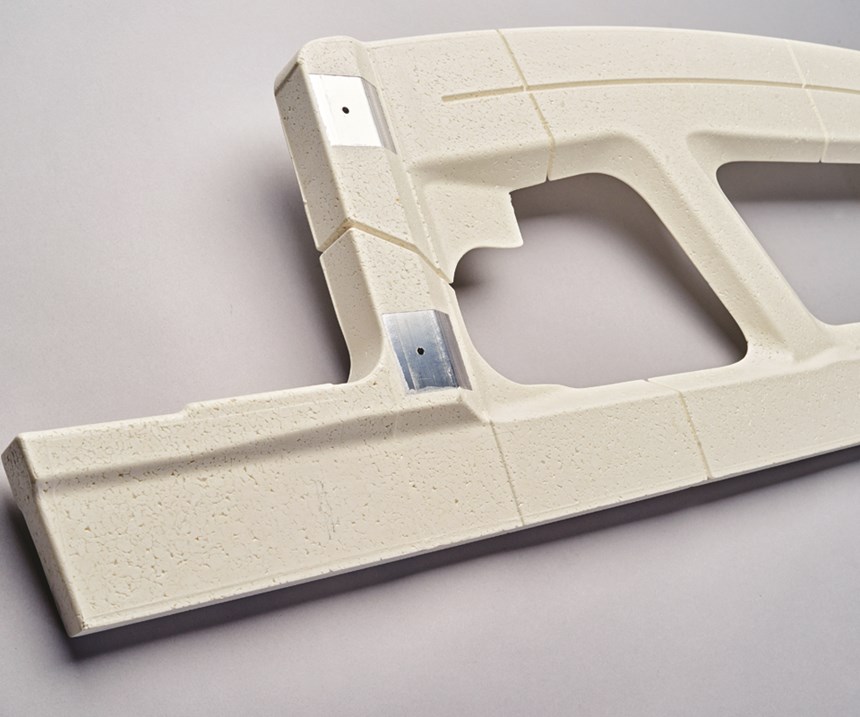

Further, says Diebold, Audi wanted to make some of the R8 Spyder composite parts using foam-cored sandwich construction, particularly in the B-pillars and the upper rear wall. Roquette says the decision to use foam core was driven by a desire to reduce the amount of carbon fiber in each structure, and, in the B-pillars, consolidate parts and increase strength and stiffness. Enhanced B-pillar performance is critical for the Spyder, a convertible, when the vehicle’s roof is down. In a non-convertible vehicle, stability and stiffness of the chassis is provided by the floor/tunnel section and the roof frame. With a convertible, the floor/tunnel section must provide all of the stability and stiffness.

Audi wanted a foam core surrounded by carbon fiber infused with epoxy via resin transfer molding (RTM). The main problem with this plan, Diebold recalls, was finding an easy-to-handle core material that was neither too heavy (100-150 kg/m3 density) nor so light that it was susceptible to crushing during the RTM process. Audi eventually settled on a novel solution and a relatively new product on the market, a polymethacrylimide (PMI)-based foam. “It compacts globally, is not easily crushed and is easy to handle,” says Diebold. “Other core materials were tried, but the problem of heat, cost or some other limitation did not make it possible.” He adds that the foam can be molded to almost any three-dimensional shape, allows for the integration of bosses, inserts and other metallic parts, and obviates the need for the machining and milling typically associated with foam core fabrication for composite structures. Further, Diebold describes the PMI as having a homogenous cell structure that is amenable to hydrostatic testing.

A new type of RTM

The final piece of the developmental puzzle was the refinement of the RTM process that would bring the materials together. This was not trivial because what Audi developed would, eventually, be handed off to a tier supplier for production.

Although high-pressure RTM (HP-RTM) has become a favorite of autocomposites manufacturers, and Roquette says Audi considered it, its 120-bar injection pressure — with even higher pressure at the injection point — posed a threat to the integrity of the foam cores, the use of which was not going to be compromised. This drove Audi to look for a way to reduce injection pressure without increasing cycle time. The task seemed impossible until Audi connected with researchers who were doing work with mold cavity pressure sensors to fine-tune the interaction of injection pressure, compression force and mold gap in RTM to optimize that molding process.

Roquette says Audi’s research, in conjunction with the researchers, revealed that if cavity pressure was the governing and primary variable during the molding process, then mold gap height and press force could be moderated and adjusted to produce a cycle as fast — if not faster — than HP-RTM provides. Audi calls its process ultra-RTM. For the R8 Spyder sandwich structures, injection pressure does not exceed 40 bar, mold gap opens to as much as 0.6 mm, press force maxes out at 500 MT and mold temperature does not exceed 123°C. With this new process, the injection time can be reduced to 15 seconds and the overall cycle time to less than 5 minutes. This also means parts can be made on a smaller, less-expensive press, using less energy, and without risking the integrity of cores.

Future developments

Roquette says that when Audi first set out to manufacture composite parts for the MSS, the strategy was to employ European autocomposites fabricators who might have the capacity and expertise to efficiently and quickly design and make the parts the OEM required. Ultimately, however, Audi decided that such composite materials and processing expertise should be developed in-house first.

“What we learned is that if we really want breakthrough technologies in a field like composites, then we have to understand it on our own, and we have to develop it on our own,” Roquette says. “We have a huge team, and we were just very focused on this project, every day.”

When it came time to transfer the material and processes Audi developed for the R8 to its two European automotive composites suppliers, which would do the actual manufacturing, there was some uncertainty: “This is not technology we could have bought on the open market,” Roquette says. “So, when we approach our suppliers, who have manufactured composites for a very long time, it is very different for them to accept this new technology. And we did give them this technology and showed them how to use it, but in the end, making good parts is up to the supplier, so they are taking a great risk. In this way, it is not easy being a supplier to an automotive OEM.”

Lessons learned did not end with the 2016 R8 Spyder. In 2017, Audi introduced its four-seat, luxury-class A8, with a carbon fiber composite rear wall and upper rear shelf, both made via ultra-RTM. As to higher volumes, there is still work to do, says Roquette: “The cost of a finished carbon fiber part is still too high. Now we are on a level where we have to look at every point. It is not just the fiber price, it’s not just the speed of RTM. It’s everything. Resin price, adhesive price, the whole chain. We must use new ideas.”

Related Content

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More