Automated filament winding enables competitive composite cylinders

Carefully controlled, robust, volume processes offer fabricators of Class IV LPG/CNG tanks a means to meet increasing demand in Europe and Asia.

High-pressure gas storage vessels are one of the largest and fastest-growing markets for advanced composites (Read Chris Red’s composite tank market assessment in “Pressure vessels for alternative fuels, 2014-2023” online under “Editor’s Picks” on the top right). The majority are used to store and transport liquid propane gas (LPG) and compressed natural gas (CNG). In an October 2015 report, market research firm Lucintel (Irving, TX, US) forecast growth in the global market for composite pressure vessels at a CAGR of 8.7% from 2015 to 2020, driven by an increased demand for CNG-powered vehicles and the need for gas cylinders that weigh less but have greater gas capacity than conventional steel vessels. The continuing global push to cut carbon emissions is driving parallel growth in LPG’s use not only as a transportation fuel but also, propelled by government initiatives in India, Indonesia, China and Africa, as a clean cooking fuel.

Europe is the largest growth market for CNG tanks; demand for LPG tanks is greatest in Asia. Perhaps it is no surprise, then, that situated in between these two regions, a supplier of composites manufacturing solutions, MIKROSAM (Prilep, Macedonia), has capitalized on this trend by delivering automated production lines for LPG and CNG composite tanks that can operate three shifts per day and output up to 500,000 LPG tanks per year, attended by as few as four operators. MIKROSAM’s recent design and construction of the largest such line in the world, to date, for a customer in India, offers a glimpse into the world of automated composites manufacturing. Such a system reveals both the challenges that must be overcome and the opportunities that await the pressure vessel industry as a whole.

Process automation prerequisites

Although MIKROSAM has built filament winding and prepregging equipment for 20 years, and automated fiber placement and tape laying systems since 2007, its workforce mirrors that of Silicon Valley. Average employee age is 30; 50% are engineers and 10-15% hold either a Ph.D or engineering MBA, the latter a standard for technical companies in Europe.

MIKROSAM has the capability to produce equipment for a wide range of composites manufacturing processes under one roof, and is adept at filament winding technology, having produced 30 fully automated systems, but many more standalone winding modules.

“In the past five years, we have seen many more inquiries for automated or semi- automated systems,” says sales manager Dimitar Bogdanoski. “Most of our innovation in filament winding has been in automating processes that were previously done manually, for example, automatic cut and restart of the fiber reinforcement, once winding is complete.” Automated resin mixing and filling is also common now, as is automated loading and unloading of the plastic liners, when producing tanks, and of the filament winding mandrels used when producing rollers, driveshafts and composite isolators.

Another key constituent is the central control system, which MIKROSAM calls TCON. It manages all modules in the integrated production line from one location while it records all important parameters, such as resin, oven and production-environment temperature and humidity, fiber and resin type, operator name and the date and time of production start and stop, etc.

“Every single tank has individual passport data, which is its unique paper trail,” Bogdanoski observes. Quality and traceability are indeed important, because these production lines are for Type IV tanks, made from carbon and/or glass fiber filament wound over a plastic liner, where the composite carries all of the structural loads. They weigh less than Types I, II and III, but are also the most expensive (Read more about pressure vessels tank “type” designations in “CNG tanks: Pressure vessel epicenter” online under “Editor’s Picks” on the top right). It is important that the automated equipment turns out the product precisely as designed, but also that it has the capability for future upgrades and the capacity to generate Big Data, now considered a prerequisite for manufacturing productivity per Industry 4.0 and the Internet of Things (CW guest columnist Bob Griffiths observed the emerging impact of Industry 4.0 in “CFK-Valley Stade Convention 2015 report” and CW guest columnist Avner Ben-Bassat championed “Applying the Internet of Things to composites production efficiency” online under “Editor’s Picks” on the top right).

Design, build and pre-acceptance

Each automated filament winding production line begins with close discussion between MIKROSAM and its customer. Together, they determine the target tank sizes, the definitions of the fibers and resins that will be used, the level of automation desired and the standards to which the tanks will be certified. MIKROSAM then designs the line and its individual modules, using Autodesk software (Autodesk Inc., San Rafael, CA, US).

After customer approval of the final design, production begins. “Some of the modules and parts we manufacture ourselves, some we buy off the shelf and some we subcontract,” explains Bogdanoski. But the emphasis is controlling capital investment by not “reinventing the wheel.” “For example, we buy robots and motors from well-known suppliers. Our strategy is to provide the highest quality and most affordable cost per the system design.”

In parallel, MIKROSAM develops the control software and data acquisition system. “We then assemble all of the units and integrate the control system in our Macedonia facility,” says Bogdanoski. “We set up the complete line to produce parts with the exact fibers and resins to be used so that the customer can see the line in operation, inspect it and discuss any issues,” he adds. After customer approval, the line is disassembled and transported to the customer’s site for re-assembly.

Design and pre-acceptance construction takes approximately 12 months, followed by one to two months for the MIKROSAM team to complete the installation at the customer site. “We then do a trial production run,” says Bogdanoski, “and stay for start-up assistance, including training of operations and maintenance personnel.”

MIKROSAM offers continued support via a remote maintenance system. “The customer connects the production line to us via the Internet,” Bogdanoski explains, “and our personnel then do maintenance on the production line software and control systems, providing any updates available.” He notes this is normal in European factories. MIKROSAM provides software updates to the customer for the lifetime of the automated manufacturing system, free of charge.

Anatomy of an automated line

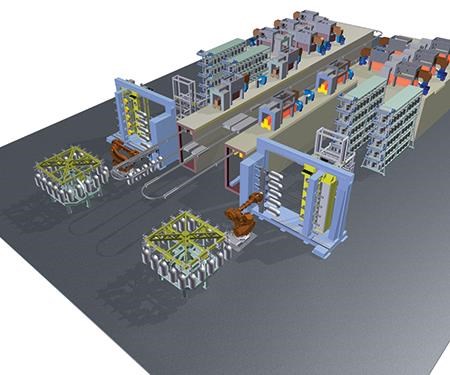

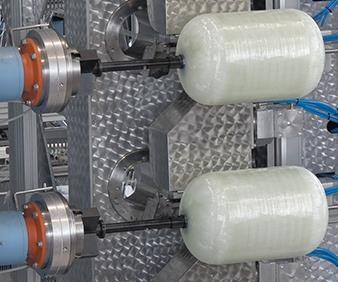

Illustrated here is the functional result of a plant design (Step 1 photo, at left) for production of LPG tanks that called for two complete production lines, side by side. The one on the right is a mirror image of the one on the left. Each is capable of winding five vessels simultaneously and is equipped with a continuous, rather than a batch-process, curing oven. The first module in each automated composite LPG tank production line blow-molds the plastic liners. Because MIKROSAM does not produce plastics blow-molding equipment, it partnered with a German manufacturer for these modules. On each line, the tank liners are loaded onto a rotating, four-sided carousel, from which a robotic arm picks up five liners at a time, with shafts already welded onto them to enable handling and winding (Step 2).

The robotic arm then moves the liners into the automated filament winding module, which MIKROSAM designed and built (Step 3). Each liner’s shaft, which serves as a winding spindle, is inserted into a gripper (Step 4). With all five shafts inserted, liners are ready for winding to begin. Glass fiber yarns for winding are drawn from multiple creels (Step 5). This line used a relatively simple creel system, but enclosed creels with mechanical or electronic tension control can also be used. Computer-controlled electronic systems are the most precise, providing servo-controlled tension of each fiber.

The yarns are then drawn into an impregnator with resin bath (Step 6). “We have very good control of the resin content,” notes Bogdanoski. This is enabled by precise adjustment of the doctor blade, which regulates delivery of the resin onto the fibers: “There is no dripping, which saves a lot of cost for the customer, not only in saved resin but in tank surface preparation and equipment maintenance.” MIKROSAM also has a patented automated cut and restart, so there is no lost time or labor expense required between the end of wrapping one set of tanks and the beginning of wrapping the subsequent set.

Winding typically takes 5-7 minutes, depending on the LPG tank size (Step 7). After winding is completed, the line’s robotic arm removes the set of five wound tanks and places them into an automated monorail conveyor system (Step 8). The tanks are then moved into that line’s curing chamber, which cures the composite tanks at 60-120°C, depending on the type of resin used (Step 9).

Curing ovens can be equipped with gas or electric heaters, per the customer’s specification. The standard resins used in LPG tanks require 2-3 hours of cure at these temperatures. For CNG tanks, the resins are different and typically cure in 3-4 hours, although they occasionally can require up to 10 hours for cure. “All of this is driven by the tank design,” explains Bogdanoski, pointing out, “We design the curing oven based on the range of resin systems the customer wants to use.” The tanks could cure more quickly at higher temperatures, but this would exceed the limit for the plastic liners.

After cure, tanks are robotically removed and placed into another chamber, where a coating is applied to protect against ultraviolet (UV) radiation, required for some types of LPG tanks, according to certain industry standards. The UV coating modules may be automated or manual. In the LPG lines, here, they are semi-automated: Tanks are machine-rotated while the coating is sprayed on manually by a technician. Once this coating has dried, the shafts used to connect the tanks to the filament winding machine are removed; tanks are machine-advanced but each shaft is removed manually, using a gun-like tool to quickly unscrew the shaft and bin it for reuse. The tanks then proceed to a single testing station, shared between the two lines, where, according to this customer’s specifications, each tank must be hydro- statically tested to its working pressure (Step 10).

The testing station for this plant’s LPG lines is semi-automated — 5-10 tanks are manually placed into the testing unit, but the subsequent testing is done automatically. In other MIKROSAM-built lines, the testing station is fully automated. A robotic arm places 5-10 tanks into the test rig, and then removes them after the hydrostatic test is completed and results are evaluated. Because this section of all MIKROSAM automated composite tank lines includes proprietary technology, it is not shown in the manufacturing step photos below. It does, however, conclude this largest LPG composite tank operation. Tested tanks are manually removed from the test station, outfitted with valves and covers, and prepared for shipment.

Challenges and future opportunities

Although this dual production line is not the most highly automated system MIKROSAM has produced, it still represents a significant achievement. Bogdanoski points out that the customer elected to semi-automate the final stations in each line to provide some employment for technical staff, while automating where possible to ensure quality. The challenge came in the requirement to produce many different products on one line. “For many of our projects,” he says, “the customer wants to produce different sizes of tanks, changing both length and diameter. Thus, we have to make all of the modules accommodate this change.” Although for this LPG line, only the length changed, for a CNG tank line currently in process, the customer wants to produce several batches of tanks with a 200-mm diameter and 1m length, for example, and then switch immediately to producing 400-mm diameter and 600-mm long tanks. The line must be able to do this automatically, adjusting all of the modules in the system to this change, says Bogdanoski. “So not only does a new winding program have to be generated, but the handling units and curing oven also must be adjusted to accommodate the new dimensions. This was one of the hardest requirements to meet, but we managed to realize it.”

MIKROSAM’s most recent tank production line, scheduled for customer review this month, is fully automated and reportedly will output 50,000 Type IV composite CNG tanks per year.

“It is the only one of its kind in the world,” claims Bogdanoski, adding that, upon approval, it will be delivered to one of the top automotive manufacturers in Europe. This annual production rate is actually quite high. LPG tanks typically have a working pressure of 20 bar, but CNG tanks operate at much higher pressures (to 250 bar) and therefore require longer winding times.

MIKROSAM also is designing a combination production line, which will comprise the largest automated LPG and CNG tank manufacturing systems in one location. “This market is very interested now in alternative fuels to diesel,” Bogdanoski observes, “so filament wound composite tanks for natural gas and hydrogen are gaining in favor, and automation is key in delivering both the quality and cost required.”

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreThe state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

CNG tanks: Pressure vessel epicenter

In the pressure vessel market, there are a number of competing designs offered around the world, including a small number of new CNG Type V “linerless” designs, which have recently received regulatory approval for use in vehicle applications.

Read MoreApplying the Internet of Things to composites production efficiency

The Internet of Things is defined as the technology of connecting devices, systems and services that goes beyond mere machine-to-machine communications. Guest columnist Avner Ben-Bassat, president/CEO of Plataine Ltd. (Waltham, MA, US) calls for its implementation in the aerospace manufacturing workplace.

Read MorePlant tour: A&P, Cincinnati, OH

A&P has made a name for itself as a braider, but the depth and breadth of its technical aptitude comes into sharp focus with a peek behind usually closed doors.

Read More