Automated Preforming, Part 1: Numbers and Landscape

CW’s multi-blog series on preforming begins with an overview and quick look at the numbers: 1-minute take time, 10-15 seconds per layer, 490-kg/hr and 3.5 million parts/year. Are you ready for serial CFRP production?

This is part one of a seven-part series about preforming. For more on this series, click the links below:

part two, part three, part four, part five, part six, part seven.

Also, don’t miss the printed version of this series:

Preforming Goes Industrial, Part 1 and Part 2.

Made in 40 seconds using the automated QSP line, this preform and part integrates 13 patches of 1.5-, 2- and 3-mm thick organosheet and UD tape with fittings for attachments. SOURCE: CETIM.

In my 2015 article, preforming was seen as a bottleneck, with cutting, positioning and forming of fabric layers taking much longer than the molding cycle. “Right now, molding is not the time-critical part of the process,” said Matthias Mayr, head of project management at Engel Austria’s (Schwertberg) Center for Lightweight Composite Technologies. The target for preforming was to match the 1- and 2-minute molding cycle times, which—according to a 2015 presentation by automotive supplier Faurecia (Nanterre, France)—enable 1,000 and 500 parts per day, respectively, for mass production of 200,000 and 100,000 parts per year.

Today, there are multiple technologies and players that claim the ability to produce high-quality, continuous fiber preforms in 90, 60 and 40 seconds. In fact, production of 100,00-500,000 parts per year is just the beginning. According to Thomas Dobiasch, head of sales for Compositence (Leonberg, Germany), “We have also demonstrated with BMW that we can preform 3.5 million parts per year with an output of 250-kg per hour on one machine.”

Dieffenbacher Preform Center |

Compositence AFP |

Quilted Stratum Process |

Copro Technology |

Applus+ Laboratories |

Development of Different Technologies

From 2005-2009, automated preforming consisted mainly of 3D textiles for aerospace applications and directed fiber preforming for resin transfer molding (RTM) of automotive and transportation parts. Ford actually worked on chopped-fiber preforming in the 1990s. By 2008, it had partnered with Sotira Composites (Saint Méloir des Ondes, France) to make 50,000 parts per year for Aston Martin's DB9 coupe, DB9 Volante, V8 Vantage and V8 Roadster models. The Programmable Powdered Preforming Process (P4) technology was originally developed by Owens Corning Composite Solutions (Battice, Belgium) and Aplicator System AB (Molnlycke, Sweden). A robotic arm sprayed chopped glass fiber and binder (3-5 percent by weight) onto a part-shaped screen through which vacuum was applied. The preform was consolidated using heat to melt the binder and then molded using RTM. There will be a blog later in this series about an adaptation of directed fiber and fiber deposition preforming for both carbon fiber and increased automation.

A six-axis robot at Sotira Composites sprays chopped fiber and binder onto a screen to produce preforms for RTM automotive parts. SOURCE: CW, Sara Black.

During the early 2000s, stacked fabrics were used as preforms for RTM, but these were mostly assembled by hand for aerospace applications. In addition to dry bindered fabrics, stacked pregreg can also be used as an RTM preform via the Same Qualified Resin Transfer Molding (SQRTM) process developed by Radius Engineering (Salt Lake City, UT). Parts made using this method, albeit with the manual layup, include a helicopter roof and 7.4 m long outboard flap for the Airbus A320 aircraft. Recently, aerospace manufacturers have sought to automate this preforming method and Composite Alliance Corp. (Dallas, TX, US) won the ACE Equipment and Tooling Innovation Award at CAMX 2016 with an automated cell that can produce 3D preforms from dry fiber or prepreg. It features intelligent automation and improved stacking, using a robot with special grippers to pick, place and fold plies into 3D geometry and then perform hot debulking with an integrated camera control system for ensuring quality, repeatability and accuracy.

The robotized preform cell can build preforms from dry fabrics or prepreg.

SOURCE: Composite Alliance Corp.

The one exception to the early, less-automated preforming technologies was Fiberforge’s Relay system (supplied by Dieffenbacher), which used a modified form of automated tape laying (ATL) to build up tailored blanks from unidirectional-reinforced thermoplastic tape, which were then molded into parts. During this time, there was also some stitching of 2D fabrics to form 3D preforms (e.g., PRSEUS preform).

Both ATL and automated fiber placement (AFP) have evolved significantly, which will be discussed in later blogs and also in the two-part print article on automated preforming currently slated for our July and August 2017 issues. The Dieffenbacher Fiberforge Relay system is being used by Tri-Mack (Bristol, RI) and now TxV Aero Composites to produce thermoplastic composite parts for aerospace. Dieffenbacher is also promoting its update to the system, claiming rates of up to 490-kg per hour and 4 m2 parts, up to 5 meters per second for preforming with thermoplastic tapes and ability to combine up to four different types of tape in one part (e.g., carbon fiber and glass fiber). Another player is Coriolis Composites (Queven, France), a long-time leader in AFP technology. It actually started in 2000 with applications for wind blades and automotive parts, which demanded dry fiber for a low cost. Coriolis has produced flat preforms for the Audi A8 B-pillar made from dry unidirectional carbon fiber and is a partner in the DYNAFIB project, where it preformed glass fiber/polyamide thermoplastic prepreg tape into a loop which was then overmolded to produce a composite engine mount.

Coriolis Composites has made preforms for B-pillars (left) and engine mounts (right).

SOURCE: Coriolis and CW, Sara Black.

Perhaps the best example of 3D woven textiles for RTM parts is Albany Engineered Composites’ (Rochester, NH) production of preforms for the carbon fiber reinforced plastic (CFRP) fan blades and fan case in the Leap jet engine powering Airbus A320 neo, Boeing 737 Max and COMAC C919 aircraft (click here for more).

3D woven textiles provide efficient preforms for the RTM fan blades and fan case in the Leap aeroengine.

SOURCE: Albany Engineered Composites.

Meanwhile, stitching 2D fabrics has been recently updated through the 2016 startup company Seriforge (San Francisco, CA). It is using digital technology to decouple 3D textile preforming from traditional loom-based broadgoods and is instead migrating toward a 3D printing paradigm where multiple different 2D materials—woven or uni fabrics, veils, plastics, films—are cut, oriented, stacked and then stitched using carbon fiber—vs. traditional nylon or polyester fiber—without knots or loops to degrade load-bearing. Seriforge’s long-term target is 10,000-20,000 preforms/parts per month using a single automated processing line.

Seriforge uses modern digital technology to speed and reduce error in automated cutting, orienting and forming of 2D materials into 3D preforms which are then stitched and z-direction reinforced using carbon fiber/other yarns.

SOURCE: Seriforge.

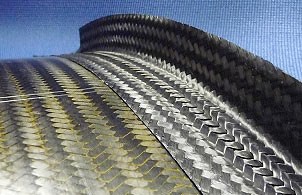

Before using 3D woven fabrics for its aeroengine fan cases, GE Aviation (Evendale, OH) used a braided preform made by A&P Technologies (Cincinnati, OH) for its GEnx engine, which was well into production by 2012. By that time, braiding was also being used as an RTM preform for bicycle frames and other sporting goods, as well as automotive and truck parts. An example of automotive parts are the roof rails in the BMW 7 Series. An alternative to braiding is 3D knitting, which I reported on last year via the RT2i process.

|

|

Braided preforms are being used for RTM bicycle frames and automotive parts,

as well as a variety of aeroengine parts, like the GEnx fan case.

SOURCE: BMC and BMW (top) and A&P Technologies (bottom).

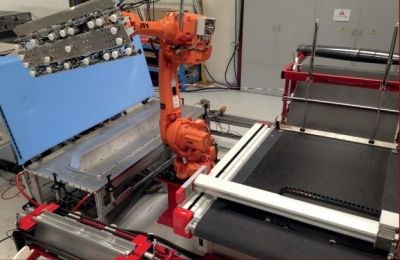

Also by 2012, Dieffenbacher (Eppingen, Germany) had introduced its Preform Center for automating the cutting, stacking and drape-forming of fabrics prior to RTM. Achieving the same steps, Broetje Automation’s (Rastede, Germany) Composite Preforming Cell was on the market by 2013 and by 2014, similar, customized systems were being supplied by Composite Alliance Corp and Fill (Gurten, Austria).

By 2013, tailored fiber placement (TFP) using modified embroidery machines was also being used for automating composite preforms. A recent example which I will blog about soon is the Lightweight Recurve Bow Riser which was developed by the Leibniz-Institut für Polymerforschung Dresden e.V. (IPF, Dresden, Germany) and won an innovation award at JEC World 2017 (Paris, France). CFRP bow risers weighing 1,000-1,350 g have not been able to cut much weight vs. aluminum designs (950-1,400 g). However, IFP was able to use topology optimization and actualize this load-efficient design using TFP carbon fiber preforms to cut weight by 40-percent to 600 g. Waste was also dramatically reduced.

TFP achieved a 40-percent weight cut vs. aluminum for this recurve bow riser developed by IPF.

SOURCE: Leibniz Institut für Polymerforschung (IPF).

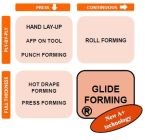

At SAMPE Seattle 2014, Arne Stahl and Henrik Borgwardt of Copro Technology (Braunschweig, Germany) gave two papers on their continuous roll forming process including “Quality controlled continuously formed NCF preforms”. At SAMPE Long Beach 2016, Jordi Brufau, executive director for Applus+ Laboratories (Barcelona, Spain) presented the paper “A+ Glide Forming System/Automatic Stringer Manufacturing Technology”. Both processes were initially targeted at complex aircraft stringers and curved fuselage frames, for example, T-stringers and omega-stringers with joggles (bump-outs/local changes in profile shape) and localized reinforcements. Meanwhile, Broetje Automation had worked with Airbus to develop a similar process and won a JEC Innovation Award for their Continuous Composite Preforming System (CCPS) in 2011.

|

|

|

Broetje (left) and Copro Technology (center) have developed continuous preforming processes while Applus+ Laboratories has introduced Glide Forming (right).

SOURCE: Broetje, COPRO and Applus+ Labs

|

|

With SAMBA, Cevotec has commercialized the first fiber patch placement (FPP) production cell, which directly outputs 3D preforms with no further shaping required.

SOURCE: Cevotec.

Except for the roll-forming lines, most of the automated preforming systems above produce net-shaped 2D preforms which still must be draped and/or consolidated before being placed into a molding process. The Fiber Patch Placement process developed by Cevotec (Taufkirchen bei München, Germany) takes a different approach, claiming true molding-ready 3D net shapes by modifying ATL/AFP to cut bindered unitape into tailored-length patches and robotically placing these onto a 3D tool.

|

|

|

|

Automated preforming to speed wind blade production.

SOURCE: MAPRETEC

Automated Preforming for Wind Turbine Blades

Designed to speed composite wind blade production, 3D textile preforms for spar box caps and joints as well as blade root sections were being offered after 2010. In 2012 Pontis Engineering introduced a turnkey preform molding solution for wind blades that stacked layers of glass reinforcements on separate tools and then easily moved and joined these preformed modules into the main mold, enabling parallel processing and improved throughput. In 2014, the German partners the Institute for Integrated Product Development (BIK) at the University of Bremen (Bremen), SAERTEX (Saerbeck) and Areva Blades received a JEC Innovation Award for their research project MAPRETEC, which combined computer-defined ply shapes, automated cutting and materials handling, and automated shaping (preforming) using a novel device to apply carbon and glass fiber materials up to 130 m2 without wrinkles or displacements.

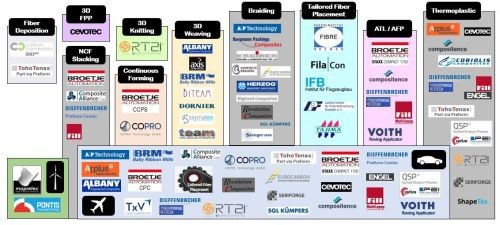

Landscape of Automated Preforming Technologies

As promised, here is my attempt to visually summarize the landscape of automated preforming technologies being used today. The companies included in this visual is not an exhaustive list but instead based on those I have seen at shows, in print or found through research.

At the bottom, I’ve tried to show which technologies are being used for wind, aerospace and automotive, but as typical with composites, most of the companies would tell you they can modify their technology/products to meet the demands of multiple markets and end-uses. So don’t rule out technology of interest before speaking with its developers/suppliers.

I’m excited about this blog series, which will include:

- My recent tour of the Quilted Stratum Process (QSP) line in France,

- Discussion of how DrapeTest has become a standard in Germany,

- The wide variety of software packages available for preform design plus drapeability and process simulation, and much more detail about many of the companies and processes mentioned above.

Preforming is one of the most active areas in composites today. The technology is developing rapidly and hybridizing. It is also integrating the latest in digital control, inline inspection and big data capability. Keep checking back throughout the next few months and thanks for reading.

Related Content

CompPair adds swift prepreg line to HealTech Standard product family

The HealTech Standard product family from CompPair has been expanded with the addition of CS02, a swift prepreg line.

Read MoreGKN Aerospace, Joby Aviation sign aerostructures agreement

GKN Aerospace will manufacture thermoplastic composite flight control surfaces for Joby’s all-electric, four-passenger, composites-intensive ride-sharing aircraft.

Read MoreSmartValves offer improvements over traditional vacuum bag ports

Developed to resolve tilting and close-off issues, SmartValves eliminate cutting through vacuum bags while offering reduced process time and maintenance.

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreRead Next

Automated Preforming, Part 2: Glide Forming

Flat layups are shaped into stringers with different cross-sections, lengths, thicknesses and curvatures using a single machine at rates up to 10 mm per second.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More