Diving deeper into composite processes

CW recently had the opportunity to visit Abaris Training (Reno, Nev., U.S.), a company that has offered advanced composite training courses for more than 30 years.

Abaris Training in Reno, Nevada, U.S. Source | CW

I have a second job. I’m a martial arts instructor and spend a lot of time thinking about the best ways to work with students to fine-tune details in their technique. I often see students reach a level of understanding and find themselves stuck, not really growing or making new progress. At this point, breakthroughs and improvements usually happen after completely dissecting something the student already thinks they know and starting over at the beginning with an open, receptive mind — a concept that in my training we call “beginner’s mind.”

Abaris instructors Mike Meringolo and Dave Castellar demonstrate vacuum bagging. Source | CW

I recently had an opportunity to visit Abaris Training (Reno, Nev., U.S.), a company that has offered advanced composite training courses for more than 30 years. I visited Abaris not as a student, but as an editor working on a video project for CompositesWorld (more about that at a later date), but to the instructors at Abaris, it was really all the same. Instructors Dave Castellar and Mike Meringolo were encouraging and patient as they walked us through various aspects of composites layup and repair. I made connections between concepts that I had an initial understanding of but hadn’t seen really thought through and experimented with in the real world. Dave and Mike experimented with layups, vacuum bagging configurations and repairs and did an amazing job of explaining the work they were doing and why. Their expert instruction gets to the heart of why things are done a certain way and what kinds of decisions and choices need to be made based on the situation at hand.

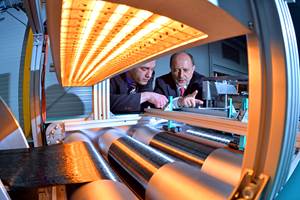

CW senior editor Scott Francis and editor-in-chief Jeff Sloan explore vacuum bagging complex parts. Source | CW

The CW team had an awesome week at Abaris. We learned a lot and had a lot of fun doing it. It was time well spent and I’m excited to say that I’m headed back later in April to take the “Advanced Composite Structures: Fabrication & Damage Repair – Phase 1” course, and report on my experiences there.

I’m coming up on my 2-year anniversary with CompositesWorld and it’s been an exciting couple of years. I came to the job without much knowledge of the composites industry and, aside from a couple of initial crash courses, have been learning as I go, through the stories I report on. Each one helps bring the bigger picture into clearer focus. As I mentioned before, as martial arts teacher, I’ve seen people struggle with certain aspects of something they’re trying to achieve, such as learning a new routine or mastering a particular technique. By approaching the task with an open mind and starting at the beginning they are usually able to overcome the obstacle and reach a new level of understanding.

And I’m looking forward to the opportunity to do just that — to having a chance to approach the material with an open mind as a beginner. I’m thrilled to have an opportunity to get my hands dirty and work with techniques that I’ve only learned about by watching others perform — to have an opportunity to take my understanding of the things I’m reporting on to a new level.

Related Content

FACC Academy begins training, onboarding operations

FACC’s newly launched training platform will address skilled aerospace worker shortages head on, offering more than 250 specialized training courses for its entire workforce.

Read MoreChemnitz University of Technology receives €6 million to expand research into "green" carbon fiber

Carbon LabFactory and InnoCarbEnergy project conduct R&D across entire value chain from raw materials through processes to structures and systems on a pilot line with technology demonstrators.

Read MoreToray, University of Chicago speed up polymer recycling R&D

A jointly developed multi-scale computational predictive technique can accurately predict viscoelasticity from the chemical structures of polymers, ramping up product maturation.

Read MoreReducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More