CAMX 2018 preview: Parabeam

Parabeam BV (Helmond, The Netherlands), part of Canadian ZCL Composites Inc., is featuring its Paraglass and Paratank 3D E-glass and hybrid fabrics, as well as its Hssue fiberglass sandwich system.

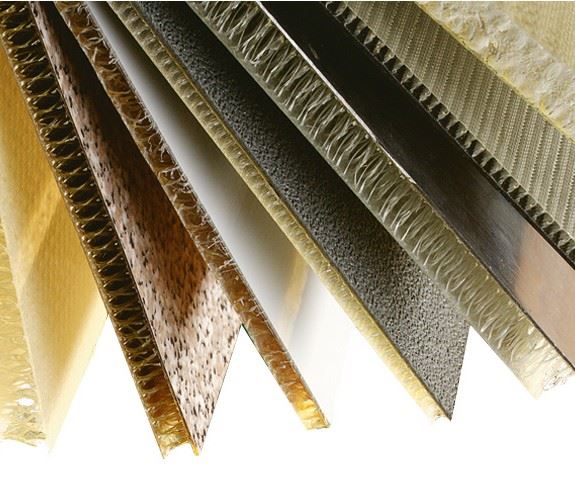

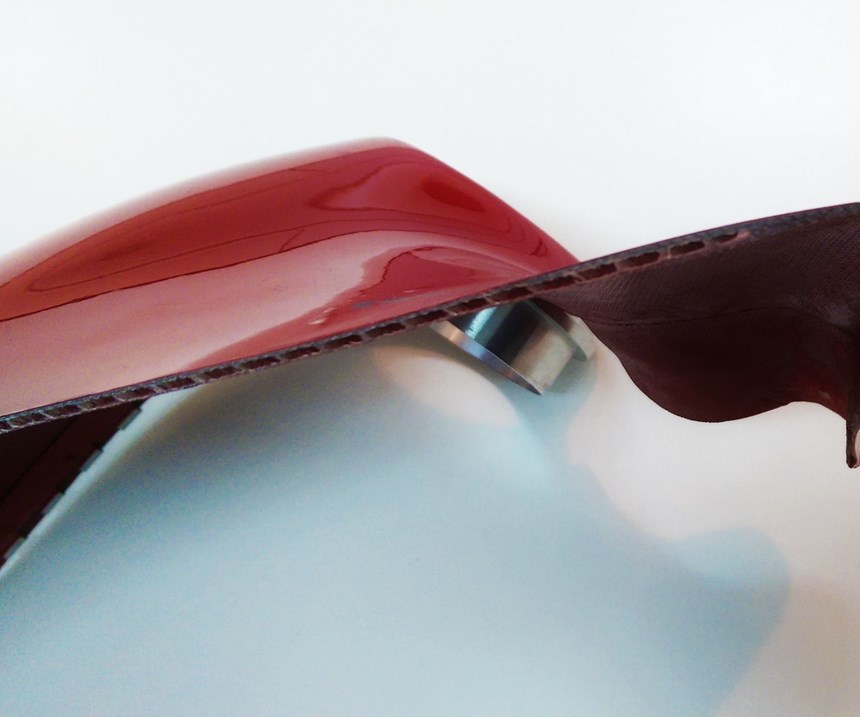

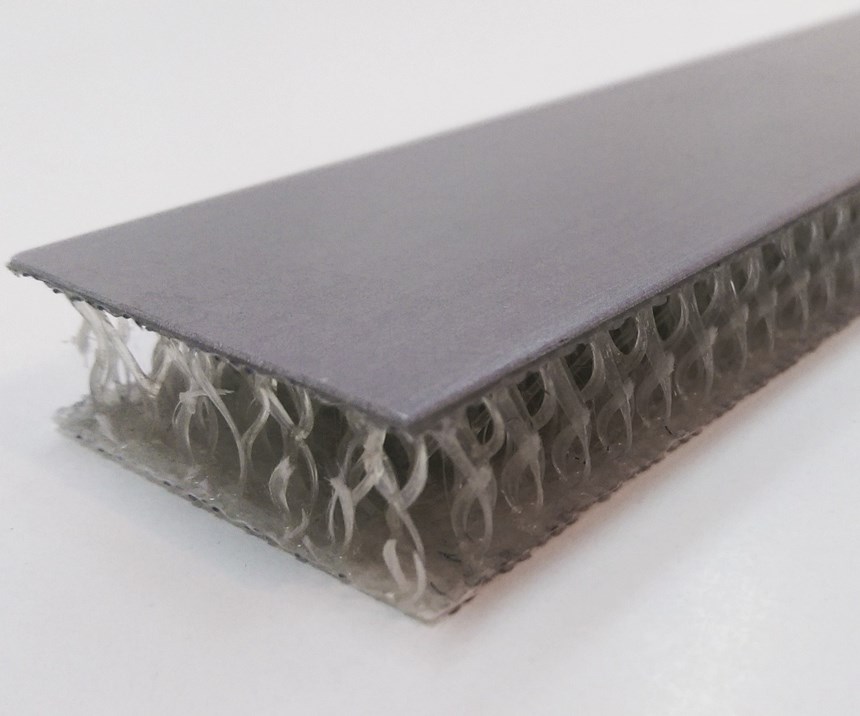

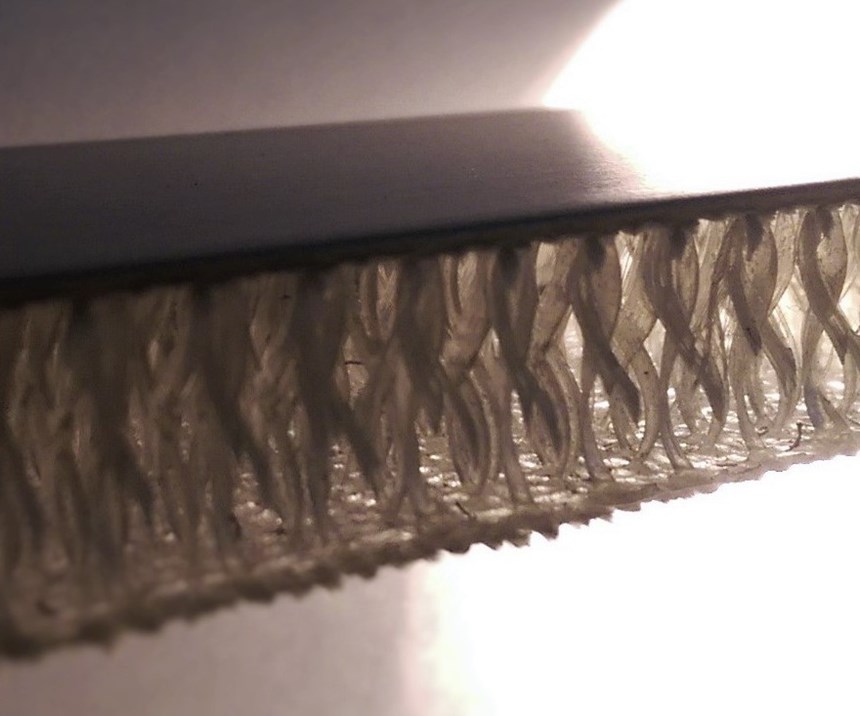

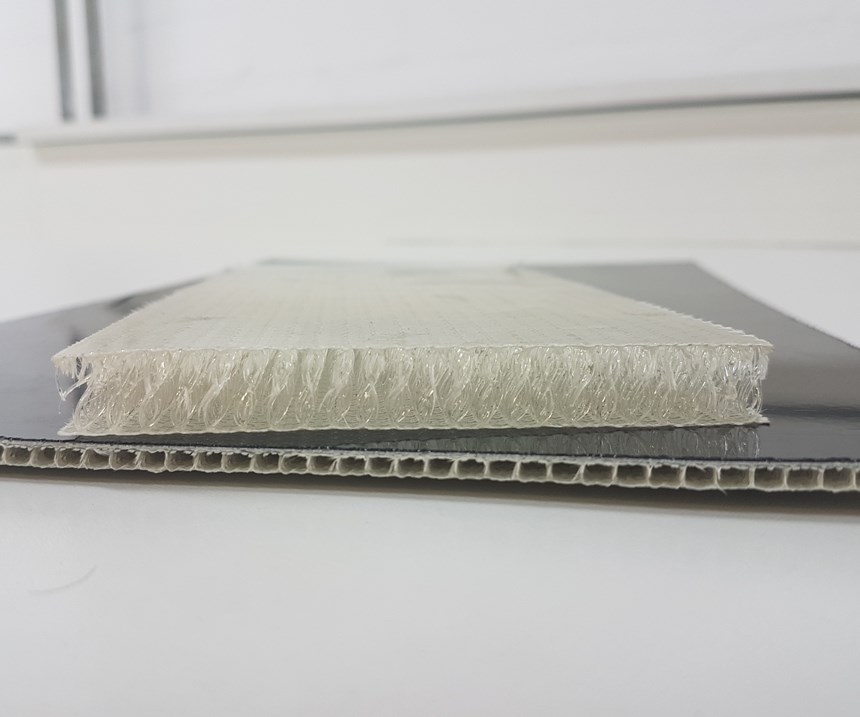

Parabeam BV (Helmond, The Netherlands), part of Canadian ZCL Composites Inc., is featuring its Paraglass and Paratank 3D E-glass and hybrid fabrics, as well as its Hssue fiberglass sandwich system. Parabeam says its products are targeted toward core applications in end markets that rely on factors such as weight, impact resistance, thermal insulation, acoustic damping or strength. Parabeam’s fabrics, combined with phenolic resin, reportedly meet performance standards like BS 6853, NFP 92501 (values M1 and F0) and EN 45545-2. Combined with polyurethane resin, the laminate becomes permanently flexible and offers significant durability. Parabeam also notes that its fabrics can be combined with foam epoxy to create lightweight panels. Standard sandwich thickness ranges from 0.118 to 0.866 inch; custom thicknesses are also available. Noted applications for Parabeam’s materials include tank liners, aircraft interiors, prop blades, public transport interiors, cladding and walls for construction, or marine superstructures. Booth J30.

Related Content

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.