Carbon fiber buys its way onboard

First used in one-off yacht and powerboat designs, where cost is no obstacle in the search for a performance edge in local regattas or around-the-world races, carbon fiber has since carved a niche in categories that were once the exclusive reserve of glass-reinforced composites, metals or wood. In applications as

First used in one-off yacht and powerboat designs, where cost is no obstacle in the search for a performance edge in local regattas or around-the-world races, carbon fiber has since carved a niche in categories that were once the exclusive reserve of glass-reinforced composites, metals or wood. In applications as diverse as production powerboats and luxury megayachts, high-end boatbuilders are employing carbon in sophisticated component designs, aided by a growing body of data derived from virtual and actual testing. As a result, carbon fiber reinforcement is reducing weight and improving performance in mission-critical components, enabling designs once impossible with other materials and, as the following case histories demonstrate, enabling boat OEMs to hold the line on costs as well.

Megayachts: Carbon comes aboard topside

While custom megayachts still cruise the seas on 100-ft-plus hulls constructed of glass-reinforced composites, aluminum or steel, above the hull, carbon fiber is enabling unprecedented design and engineering freedom.

When Taylor Olson, Westport Yachts’ (Westport, Wash.) director of engineering, joined the company in 2000, carbon fiber was already in use for its annual production of five 112-ft/34m, five 130-ft/40m and two 164-ft/50m motor yachts. “We began looking at expanding carbon fiber usage mainly for strength-to-weight and labor savings improvements,” says Olson. “The goal was to replace plies of unidirectional E-glass with a lot fewer plies of unidirectional carbon.”

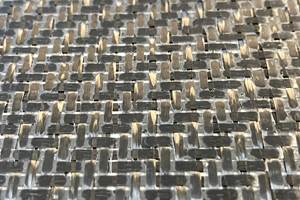

One target was deck beam caps, in which 15 to 18 plies of 18-oz unidirectional E-glass were replaced with one-third to one-half that many 20-oz uni carbon plies. Although Westport still hand lays some deck beams, the company now infuses a fair number of beams and all flat panels in its yacht decks to save weight and achieve better properties. “We get better shear properties out of E-glass laminates with infusion,” Olson explains. “Ideally, you want even deck beams, which are bending-driven (vs. hull stringers, which are shear-driven) at their shear limit in order to make the materials work most efficiently.”

Rather than infuse the beams separately and then bond them to the panels, Westport’s beams are infused in place in a second shot. The cored sandwich deck panels are made on a flat table. The bottom skin includes one ply of unidirectional carbon fiber, placed longitudinally wherever a stiffening beam will be located. When core is placed, it is omitted at beam locations. Then the bottom skin and core are infused and cured. The beams are produced by laying in carbon first, followed by the E-glass buildup and then a final layer of uni carbon so that both faces of the beam are carbon, resulting in an I-beam configuration where the flanges contain stiffer carbon material, and the all-E-glass web is optimized for shear.

Because the overall boat structure, which is primarily E-glass-reinforced, flexes more than the stiffer carbon fiber-reinforced structures, Olson notes that the 3M Co.’s (St. Paul, Minn.) very flexible 5200 polyurethane structural adhesive is used to secondarily bond the predominately E-glass deck beams to nonstructural carbon fiber panels. “It lets the boat’s structure move a bit without introducing excessive stress into the carbon panel, which is not designed to take it,” Olson explains. “This is mainly done with our exterior overhead liner panels.”

At Delta Marine (Seattle, Wash.), carbon has progressed far beyond niche status. Delta’s recently launched Laurel, a 240-ft/73.2m steel-hulled motoryacht, for example, carries more than 20,000 lb (9,070 kg) of carbon fiber in its all-composite superstructure.

According to Jay Miner, Delta’s chief naval architect and engineering manager, carbon fiber was practically mandated because the yacht’s design requirements included a very low profile. “Carbon fiber enabled us to reduce the beam depths to an absolute minimum,” he explains, “which was the only way to meet the very low side elevations of the yacht design.”

Unidirectional carbon fiber is used to in all of Delta’s deck beam caps to save weight and to help stiffen the large panels necessitated by the open spans required for today’s spacious yacht interiors. According to Miner, a typical structure in a 150-ft/45.7m Delta-made motoryacht includes web-frame spacing on 7-ft/2.1m centers transversely, and longitudinal stringers that are 6 inches to 8 inches (152 mm to 203 mm) deep and 6 inches wide. Carbon fiber also enables Delta’s engineers to maximize headroom by using shallow beams.

“Having big, open staterooms in a yacht precludes the use of stanchions and bulkheads for supporting structure. Thus, you are left with large panels and open spans.” Miner continues, “But this is what is valued in a yacht — large, beautifully appointed spaces with bountiful headroom.” Carbon fiber also reinforces Delta’s slender but highly loaded window mullions, which are frequently tied into a deck beam.

Among the most important targets are the highest points on a yacht’s top side — the radar antenna arches and mast (see bottom photo, this page). These are among the most weight critical and inherently flexible structures, thanks mainly to their slender geometries. A typical arch has a 20-ft/6.1m span with 7 ft/2.1m of headroom underneath and a 6-ft/1.2m section extending fore and aft. Arches usually have a swept-curve, wing-like shape with other structures extending on top (it is common, for instance, to have arches on top of arches).

Here and elsewhere, all-carbon construction helps engineers achieve the rigidity and styling required. It also addresses resonant frequency problems that arise when engine vibrations are carried through the yacht structure. “By using a small amount of high-modulus material we can achieve a dramatic result and obtain precisely the performance we need,” Miner notes. “Our payback on investment is maximized, even though the relative cost of carbon compared to E-glass is roughly 10x.”

Up high, Westport uses carbon in hard tops, which are two-part clamshell pieces made using very thin-skinned cored sandwich construction and measuring 25 ft/7.6m long and 18 ft/5.5m wide. Hard tops use either a 6-oz carbon/aramid 2×2 twill from JB Martin (Leesville, S.C.), featuring Kevlar aramid fiber supplied by DuPont Advanced Fiber Systems (Richmond, Va.), or a 6.5-oz all-carbon plain weave. Also, some exterior headliner panels located in upper nonstructural areas use carbon. These panels are made on 16-ft by 18-ft (4.9m by 5.5m) vacuum tables and can total as many as 10 in the 130-ft yachts and 16 on the 164-ft triple-decked vessels.

Delta uses resin infusion or hand layup depending on the size and complexity of the part. Miner also has done research to verify the physical properties that Delta is achieving with its material/process combinations. “We have our own in-house test bench where we test our composites, plus we use outside labs for doing the standard ASTM-certified coupon testing for the regulatory body approvals,” Miner says. The in-house test bench is one that Miner designed, after concluding that a second set of tests on large structures was needed, in addition to small coupon tests. Delta’s test bench can accommodate sandwich panels as long as 8 ft/2.4m (typical web-frame spacing). Its hydraulic ram can test panels to failure to determine ultimate strength and stiffness.

Westport sources its carbon through distributor Composites One (Arlington Heights, Ill.), including a 20 oz/yd2 warp uni from Comptex Inc. (La Conner, Wash.). The fabric is made with Zoltek Inc. (St. Louis, Mo.) 50K Panex 35 fiber and is optimized for infusion, using 2 percent, by weight, E-glass in the weft direction (rather than polyester stitch yarn) to enhance wetout. Delta’s primary carbon fiber supplier is Vectorply Corp. (Phenix City, Ala.). Although Delta has used tow as large as 80K in the past, it now uses mainly 24K, which is consistently available.

Both boatbuilders prefer vinyl ester resin to epoxy because it combines ease of processing and good structural properties with superior resistance to blistering. Although additional weight could be saved by making some strength-critical parts with epoxy, “there are too many complications with bonding vinyl ester to epoxy,” says Miner, observing that there are a great number of secondary bonds on a large yacht. “We keep it simple and reliable by staying with all vinyl ester.” For Olson, an additional factor is worker safety. “We have … so much hand layup occurring in our facilities that epoxy sensitization is a real concern.” Both companies use Reichhold Inc.’s (Research Triangle Park, N.C.) Hydrex vinyl ester. For Miner, the selection meant one family of resins tailored for infusion, hand layup and adhesive applications would share the same properties, facilitating engineering and increasing part reliability.

Racers and cruisers: The cost-to-value equation

Carbon use is growing among builders of high-performance powerboats, both one-off racers and production speedsters called cruisers, but where it is used in the boat structure differs widely.

A high-profile source for 22-ft (6.7m) to 145-ft (44.2m) racing and cruising sailboats, J/Boats Inc. (Newport, R.I.), designs and markets craft built by nearby Pearson Composites LLC (previously Tillotson Pearson Inc. and TPI Composites in Warren, R.I.). The companies have 12 models in production, the longest at 133 ft/40.5m, including several limited-production (2 to 20 units) carbon-intensive designs. Alan Johnstone, J/Boats’ vice president of design, explains that the cost-to-value trade-off of using carbon fiber changes, depending upon the boat configuration. The J/90 and J/125 — high-end racing sailboats — featured hulls and decks of sandwich construction, using perforated foam core, premolded to the shape of the boat, and carbon/Kevlar and all-carbon skins, respectively, infused with epoxy resin to meet very aggressive weight and structural property requirements. For its more cost-sensitive J/145, the company used a carbon fiber product specially developed by Toray Carbon Fibers America (Flower Mound, Texas) to be compatible with vinyl ester resin. The use of vinyl ester brought the cost of the final laminate down vs. epoxy while reportedly maintaining 95 to 98 percent of the overall properties, says Johnstone. “With a production sailboat, you can’t ignore the other [boat] manufacturers and what value they are offering,” notes Johnstone. “Carbon fiber has to buy its way in.”

The J/90, J/125 and J/145 were all built using TPI’s SCRIMP (the Seemann Composites Resin Infusion Manufacturing Process). The company’s highest production volume model, the J/105, uses a carbon fiber retractable bowsprit, which is basically a carbon fiber tube that extends to support the tack (turning) loads from the spinnaker sail. Since 1992, more than 2,000 of these boats have been outfitted with carbon bowsprits, which are fabricated by outside vendors according to strict J/Boats specifications.

Unusual in the powerboat market, Outerlimits (Bristol, R.I.) produces carbon fiber parts for its high-end powerboats with a stronger postcured epoxy matrix rather than vinyl ester. At 28 to 30 boats per year, Outerlimits is not a high-volume builder, but surprisingly, its customers aren’t racers. “They use our boats for pleasure boating and poker runs,” says Outerlimits general manager Aaron Crawford, referring to rally-type events for performance boaters sponsored by the American Poker Run Assn. “However, they are looking for low weight and high horsepower. Thus, we want to build a lighter, stronger product that is more durable than the ‘one-off’ carbon fiber racing boats.” In the company’s standard models — the 39-ft/12m Quatro, the 42-ft/13m Legacy, and the 46-ft/14m Limited, carbon fiber/epoxy construction extends far beyond stringer caps and can include all-carbon decks, longitudinal and transverse hull stiffeners and engine bays. Crawford notes that the extensive use of carbon/epoxy enables Outerlimits to make a stiffer, stronger boat using less material. “There is no premium for use of carbon fiber in our standard production models,” he notes.

Carbon’s use in the deck significantly reduces the boat’s weight. “You can have an extremely efficient hull bottom design, but it won’t deliver the performance if the boat is heavy,” says Crawford. Further, a carbon deck lowers the boat’s center of gravity and optimizes its planing, stepped-hull design. “The center of pressure has to be exactly where you want it to be,” he says, “for planing and speed and for handling control while making turns at 90 mph.”

For its 51-ft /15.5m GTX, the company adds an all-carbon hull and aramid honeycomb-cored bulkheads (Nomex, supplied by DuPont). Crawford says the goal was to build the GTX lighter, stronger and stiffer than standard models to generate greater speed with the same horsepower. “The weight savings from all-carbon fiber and re-engineering the laminate is maybe 10 percent,” he says, “but then we augment this by using Nomex and other weight-saving tactics.”

The carbon/epoxy decks and hulls are sandwich constructions, featuring Corecell styrene acrylonitrile (SAN) foam, supplied by Gurit (Magog, Quebec, Canada). According to Crawford, the SAN foam delivers a significant level of impact resistance and durability with no negative side effects. “Our boats are frequently painted with dark colors, and we had issues with outgassing using other foams,” he explains.

Although some small parts are prepreg, Outerlimits wet lays all large-scale components. “We build quickly anyway, so prepreg does not save us time, and our facility is air-conditioned, so we already control our environment and properties.” For wet layup, Outerlimits uses two older, manual, roller-type impregnators, which have been converted for pneumatic control. “Our modifications allow us to control the wet out of the material very precisely,” he says. “Our component weights do not vary by more than 2 percent.” Further, resin, reinforcements and core for each component are weighed prior to construction and the finished boat is weighed, using load cells. “Our weights are so consistent that I can tell what options have been installed on a given model by how much it weighs.” Outerlimits lays up outer skins and core, then vacuum bags and cures them in its in-house-built computer-controlled oven, made using components purchased from oven supplier Watlow Electric Mfg. Co. (St. Louis, Mo.). Then the inner skin is wet layed, bagged and cured. The epoxy parts reach initial cure at room temperature and then are postcured in the oven at 140°F/60°C over a 26-hour period, including an eight-hour dwell.

The Outerlimits staff has a long history in Nomex-cored carbon epoxy sandwich construction. Many of its laminating crew came onboard when Outerlimits bought nearby sailboat builder and subcontractor Carroll Marine. Some of the former Carroll Marine staff worked with Gougeon Brothers (now Pro-Set Inc., Bay City, Mich.) to develop its Pro-Set epoxy resins for marine construction.

Today, SP laminating epoxy (SP is the marine business division of Gurit AG, Wattwil, Switzerland) is the resin of choice. The company avoids costly, hard-to-get aircraft-grade fiber and tries to produce most parts from four basic reinforcements — unidirectional, ±45°, lightweight and heavyweight 0°/90° — to reduce inventory. Outerlimits buys from several manufacturers to ensure supply, including Gurit (Isle of Wight, U.K.), JB Martin, SEAL SpA (Legnano, Italy) and T.E.A.M. Inc. (Slatersville, R.I.), sourced through distributor Core Composites (Newport, R.I.).

Outerlimits continually looks for ways to increase carbon construction. One example, says Crawford, is its all-carbon head unit (toilet). “The unit also functions as a bulkhead, so there is a structural benefit,” he explains, “but, really, we do it purely for weight savings, and we can build it with material left over from constructing other parts of the boat, so we get significant weight savings at very little cost.”

Production boats: Optimizing carbon for infusion

Baja Marine (Bucyrus, Ohio) is a well-known producer of high-performance powerboats, including its famed Outlaw series of Poker Run boats. It currently produces 10 to 12 high-performance models ranging from 23 ft to 40 ft (7m to 12.2m) in length, valued by owners for their speed and durability. According to VP of operations Bill Regan, Baja stresses design and engineering. “We’re considered a midstream product, price-wise,” he notes, “but our customers are very loyal, and it is important for our boats to have quality designed in.”

Baja started working with carbon fiber as part of a program with Toray Carbon Fibers America’s Decatur, Ala. PAN-based fiber plant and distributor Core Composites to investigate the use of Toray’s FOE-sized carbon fiber with vinyl ester resin. According to Rich O’Meara at Core Composites, “Toray has invested significant effort and money into supporting the marine market. They see it as one of the fastest growth areas for carbon, and they have targeted some of their 2008 capacity increase into supporting Baja and other marine programs.”

The Baja program took two years and was begun, with the aid of consulting engineer Rick Strand (Impact Matrix Systems LLC, Hampstead, N.H.), to obtain better information on the actual load distributions seen by the Baja boat hulls, starting with the 30-ft/9m Outlaw model. “It is nearly impossible to find any data on the loads that boats really see in service,” Regan comments. So they modeled the overall boat design using HyperMesh finite element analysis (FEA) from Altair Engineering (Troy Mich.) and began running a variety of load simulations. They also performed in-service testing using actual boats on the water, collecting data from strain gauges applied throughout the stringer system and interior of the hull.

“The FEA and, really, the strain-gauge data collection showed us areas where the deflections were more than we were comfortable with,” Regan says. Baja also wanted to take weight out of the boats but, says Regan, “our customers push the boats hard, so we couldn’t afford to just take material out. We had to engineer strength and stiffness in. Thus, it became obvious that we needed to use some type of high-strength material because we needed to take care of the high-stress areas without adding weight.”

While Regan’s previous experience with carbon in the design and manufacture of ultralightweight racing sailboats made him comfortable with the material, he also knew that Baja could get into trouble if it used carbon fiber in the wrong place: “It definitely has a price premium, but it also exhibits catastrophic failure once it reaches its strength limit, which is just as important if not more so for our products. So we had already decided to take a conservative approach: slow and steady.” Regan says that his two basic rules of working with carbon fiber are: don’t use more than you have to, and if you add carbon in, take material out. “Our goal was to obtain load-handling and weight benefits without adding cost. We know we saved weight, but what was more important was that it allowed us to do other things.”

What other things? Baja already had moved to resin infusion for the fiberglass hull of the 30-ft Outlaw because it produced an excellent, very compact layup with good fiber-to-resin ratios. But the real push for carbon fiber came with the company’s change in its boatbuilding approach to incorporate Design for Manufacturing principles, which resulted in a completely different structural stringer system. According to Regan, most production boats use tall, narrow plywood stringers that are attached to a fiberglass liner (a thin pan bonded to the interior of the hull) using strips of resin-impregnated fiberglass fabric. “We changed to an integrated stringer-liner system, which relies primarily on geometry to provide the necessary load handling and buckling resistance, vs. foam or wood core,” he says. Not just the ordinary “egg crate” with longitudinal and transverse stiffeners, the Outlaw’s carbon stringer structure is a complex of “braces” that move outward in many directions. “We angled the liner structure to minimize both local and global deflections,” says Regan, “aligning the fiber in the direction of the load, with the ultimate goal to put mass only where it was needed to address areas of high load and/or high deflection.”

However, as Baja expanded its use of carbon fiber beyond the 30-ft Outlaw, the originally selected 36-inch/914mm wide carbon fabric didn’t fit, and the intricate geometry of the infusion preforms required so much trimming that the material was falling apart. O’Meara explains, “It wasn’t that the carbon wasn’t working, it was that the product format no longer fit the process and manufacturing needs.”

The integrated structural liner was so complex that infusion actually nullified cost savings because more time was required to kit and lay in the dry preforms than had been expended in the previous sequential wet layup process. Also, infusion required technicians to move about on the mold, which dislodged the pre-applied outer gel coat and forced significant gel coat repair. Regan concludes, “With our price point, we just couldn’t afford that manufacturing time and cost.” As a result, Baja returned to hand layup of the liner but still wanted to move forward with infusion of carbon fiber in other parts of its boats — such as infused decks. Regan reports that the company has just begun to integrate infused decks into new models.

Core Composites suggested that commercial-grade carbon fiber supplier Zoltek Inc.’s stitched warp unidirectional fabric would allow Baja to use carbon fiber with either infusion or wet layup. “It’s easy to handle because it’s stitch-bonded, so it doesn’t fall apart when you cut it,” says O’Meara. Additionally, the fabric’s polyester stitch yarn wraps around the carbon fiber bundles, holding them in place. This prevents fiber wash during infusion. Further, the stitches secure lightweight, weft-inserted fiberglass yarns stitched to the back of the carbon layer. O’Meara explains that carbon fiber has a filament diameter of 6 to 7 microns, while fiberglass is 6 to 24 microns — the larger diameter provides larger spaces in between the filaments, which promotes resin flow in fiberglass reinforcements. The lightweight fiberglass yarn, positioned at 0.5-inch/12.7-mm intervals, reportedly helps carry the resin to the carbon filaments.

Zoltek’s stitched warp unidirectional fabric is used not only in the hand-layed liner stringer caps but also in the infused hull to help control bending: “For example, we actually lay up carbon fiber in the dry preform of the hull,” says Regan, “adding it just where we need it along the line where the longitudinal stiffener will be located.” Thus, when the integrated liner is bonded in, it has a carbon fiber spar cap as well as a line of carbon fiber underneath it along the hull, analogous to an I-beam with carbon fiber flanges. Regan comments, “Because of the design-to-manufacture approach, we were able to achieve dramatic savings in overall build time — up to 25 percent per model. The carbon fiber also enables reduction in the amount of material laid up: Normally we replace at least two layers of knitted E-glass with one layer of carbon fiber material.”

Baja uses a vinyl ester blend from AOC (Collierville, Tenn.) because it gives good adhesion and also has good elongation. Regan notes, “We worked very hard with our suppliers to make sure that the sizing on the carbon fiber material matched the vinyl ester so that we could achieve the optimum adhesion.” According to O’Meara, this was part of Toray’s original goal at Baja because it realized that fiber compatibility with the resin matrix can improve the shear strength by 10 to 15 percent, and it can improve compression by at least this amount.

Baja also is using all engineered fabrics, including E-glass fabrics for the noncarbon remainder of the stringers, aligning the fibers with the loads to optimize material use. ITW Plexus (Danvers, Mass.) supplies the methacrylate adhesive used to bond the integrated structural liner to the hull. Baja has modeled the adhesive by itself using FEA and also tested it for shear strength to ensure it was possible to obtain the performance needed.

According to Regan, 10 new production models released since 2003 have carbon reinforcement in their stringers, totaling about 1,000 boats, to date, in its Outlaw, Islander Bowrider and Baja Performance series.

The company pursued a different philosophy with Baja’s own one-off racing models, the 35 Outlaw and 40 Outlaw. “The goal here is pure weight savings,” says Regan, “which actually is somewhat trickier because of the catastrophic failure behavior of carbon.” While some one-off models are all carbon, most use a hybrid fabric woven by JB Martin from Kevlar aramid fiber and Toray’s standard-modulus T700 12K FOE-sized carbon fiber. The result was roughly 50 percent weight savings vs. standard production models because, as Regan notes, this fabric is the laminate stack, with two layers on either side of a 1-inch/25.4-mm thick core.

“That’s why I said it’s so vital to understand exactly where your loads are and where to place the material,” Regan adds, noting that the boats successfully endured heavy abuse during an entire Poker Run summer series and provided valuable data that will help his team to incorporate similar construction into Baja’s standard production models and possibly a new model by early 2008.

The future: Finding a practical balance

Carbon fiber has come a long way in a short time, but no one is saying it’s reached its limit. “Expectations in the megayacht industry are always increasing,” says Delta’s Miner. “Our philosophy is to balance progress with realistic promises that can be achieved. We believe in the right balance between our historically conservative outlook and progressive opportunities. Our yachts cruise all over the world, and the ocean doesn’t play favorites. We’ll continue to use carbon fiber but only where it really buys something for the customer and where we can verify its performance and reliability.”

While carbon fiber always will have a future in select J/Boats models, J/Boats’ Johnstone can’t say for sure that its use will progress to those produced in high volumes. “There is always more pressure for boats that perform better and go faster,” he explains. “But in general, the higher the performance, the higher the price and thus, the lower the volume.”

Baja’s Regan is sure that carbon fiber will be integrated into more new production boats — a prediction that could have far-reaching effects because Baja not only designs its own models but also performs design work for other boatbuilders within parent company Brunswick Corp.’s (Lake Forest, Ill.) marine construction family.

While their carbon design and fabrication philosophies differ, these boatbuilders agree on one thing: Carbon may not be the answer to every boatbuilding challenge, but it is increasingly answering the call — and paying its way — where marine designers want to push past the limits of established technology.

Related Content

IPSA acquires bonding adhesives based on MMA technology

IPS Adhesives (IPSA) introduces a line of adhesives using acrylate and MMA technology from L&L Products for the bonding of dissimilar materials such as metals and composites.

Read MorePontacol thermoplastic adhesive films are well-suited for composite preforms

Copolyester- and copolyamide-based adhesive films eliminate the need for sewing threads or binders when stacking laminates while improving the final part’s mechanical properties.

Read MorePark Aerospace launches aerospace, MRO structural film adhesive

Aeroadhere FAE-350-1 is a curing epoxy formulation designed for composite, metal, honeycomb and hybrid applications.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More