Class A CFRP body panels: Six-minute cure

Gurit CBS-based laminate/process combo mints parts with twice the thermal performance in one-sixth the time.

With tougher emissions and fuel economy targets now in play, automakers are struggling to take weight out of vehicles without losing control of costs or sacrificing production volumes. The composites industry, in turn, is scrambling to shorten the processing times of polymers, particularly thermosets and especially those used in carbon fiber-reinforced plastics (CFRPs). Much CFRP work of late has focused on resin chemistry, to reduce the catalyzed polymer’s cure duration, and on finding out-of-autoclave processes that produce quality parts but require less time, energy and secondary finishing — bogeys that have previously driven production rates down and costs up. Toward those ends, Gurit UK (Newport, Isle of Wight, U.K.) has developed a new laminate material and “press process” that reportedly produces CFRP parts with nearly twice the previous thermal performance (200°C/392°F vs. 110°C/230°F) in button-to-button cycle times down from 60 to 10 minutes, achieving cure in a mere six minutes.

SPRINT to the finish

Called CBS 200, the new material is based on Gurit’s patented SPRINT (SP Resin INfusion Technology) CBS (car body sheet) technology introduced in 2007 for Class A automotive body panels. The new product offers the low weight and Class A surface of the previous CBS 96 grade, which was developed for low-temperature (80°C/176°F) paint ovens, but the 200 version is compatible with E-Coat. Short for electrophoretic coating, E-Coat is known in Europe as KTL, a German abbreviation for cathodic dip painting (CDP). It is the high-temperature process used to bake/cure rust preventative onto the metallic body in white. Although composites don’t need rustproofing, automakers prefer to attach panels at the start, not the end, of vehicle build.

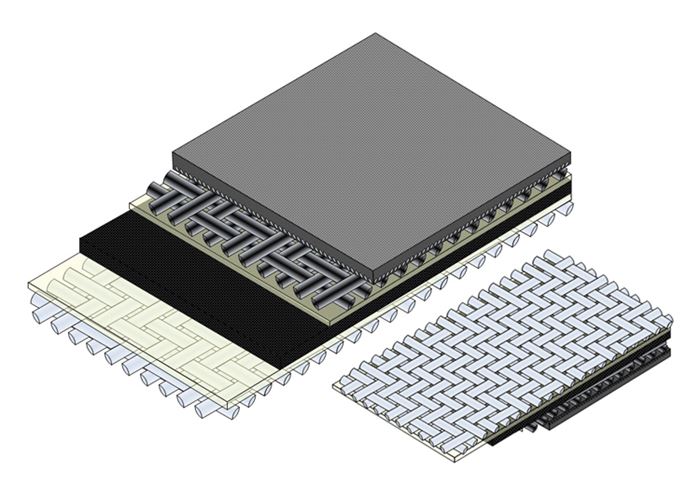

The original CBS epoxy-matrix laminate is a sandwich construction: a Gurit SF 95 surface film; a carbon-fiber fabric semipreg, typically 200g/m² (0.65 oz/ft²) 3K tow in a 2x2 twill weave; a thin (0.7 mm/0.03 inch) yet flexible syntactic foam core of epoxy/glass microspheres, which increases stiffness and buckling resistance but offers inmold conformability; and another fabric semipreg, typically glass instead of carbon, in a 400 g/m² (1.31 oz/ft²) 2x2 twill weave.

A key element of the CBS system is the highly filled surfacing film/primer, which provides a resin-rich shell that blocks fiber read-through and enhances paint adhesion. Developed inhouse, the film typically is 700 g/m2 (2.29 oz/ft2) by weight and features a solvent-free, hot-melt epoxy film sandwiched between fiberglass scrim and proprietary, finely woven thermoplastic scrim layers. Because it is flexible and slightly tacky, the film layer goes into the tool first and, during cure, forms an opaque, homogeneous surface.

Gurit attributes fiber read-through to a coefficient of linear thermal expansion (CLTE) mismatch between the resin and the reinforcement. The film, therefore, is formulated to have a CLTE intermediate between standard epoxy and carbon fiber. After it is cured, the panel is sandable and can be prepared and painted like metal or sheet molding compound (SMC). Because there’s no solvent in the film that can be trapped during cure, voids and paint pops are greatly reduced. As a result, Gurit says, less finish work is needed and the film’s surface quality is a key driver for use of this technology.

The fiber layers — whether carbon alone or carbon and glass — are single-sided semipregs that are produced, much like the surface film, by extruding a mix of epoxy and catalyst as a film and then laying woven fiber on top. Featuring carbon on the part’s A surface and glass on the B surface, the thin laminate offers stiffness comparable to steel and aluminum but is less prone to twisting than an unbalanced carbon/carbon laminate with a resin-rich surface, says Gurit. The partially impregnated stack and central syntactic foam layer are reportedly less expensive and lighter than many competitive systems and offer good conformability/drapability. Indeed, laminate edges typically are rolled over a loose edge tooling bar to mimic the rolled edge that is common in stamped steel and aluminum. This eliminates postmold edge trimming.

Although the new product is based on previous SPRINT CBS technology that uses epoxy-based resin and a similar structure/ply schedule, the chemistry has changed throughout the laminate (surface film, semipregs and syntactic core), and scrims have been eliminated from the surface films, says Gurit’s managing director Martin Starkey. The new system reportedly provides better fiber wetout, greater thermal stability/higher glass-transition temperature (Tg), faster cure and a very low, controllable exotherm — properties usually not found together.

Although other epoxy producers offer high-Tg grades (typically for aerospace use), the cycle time usually goes up with the Tg. Gurit’s new proprietary formulation delivers high Tg with shorter cycles. Starkey also says that its epoxide expertise and long experience molding thick laminates for wind turbine blades and boat hulls helped Gurit control exotherm while significantly reducing cure time.

The previous epoxy cured in 60 minutes, offered a Tg of 110°C/230°F, and could withstand extreme ambient temperatures (e.g., those likely in a black car sitting outside on a 30°C/86°F day). The new technology cures in six minutes, offers a Tg of 200°C/392°F and, although it loses some modulus above its Tg, it can endure 10 minutes in the E-Coat oven — another step toward making CFRP panels easier to use on auto assembly lines.

Starkey notes that because it does not produce its own fiber, Gurit has the flexibility to try many fiber sources and types (e.g., nonwovens and crimps). “Fiber choice can be optimized in our process,” he points out, “so we tend to source in, and that gives us a lot of flexibility to go with whatever the end-component’s mechanical performance requires.” In the fiber segment, he notes, “that’s a benefit, because there are more interesting products and players every day.”

New press process

To the new laminate technology, Gurit has added a new press process to form the panels. Previously laminates were molded in a vacuum-bag/out-of-autoclave setup that accepted a variety of tooling types (carbon composite, machined steel and nickel shell). To help ensure a good molded finish on the part backside, the press is fitted with intensification tools. These provide a better B-side aesthetic on panels such as fenders that are not bonded to an inner panel, and they ensure a consistent surface and gap between bonded panels, such as roofs and hoods. Previously, these lower-cost, rigid structures (a/k/a caul plates) were manually inserted between the laminate and vacuum bag, which is one big reason why the old process took 60 minutes.

To keep heating/cooling systems simple and tooling costs down, the press and materials that go into it have been designedfor processing at a constant molding temperature (200°C/392°F) — more like thermoplastics than typical thermosets — and relatively low pressures. “The preform can be hot loaded and demolded without post-cure,” Starkey says. “A fast 10-minute cycle time is achievable.” Unlike resin transfer molding (RTM), the new system doesn’t need complex injection equipment to get resin into the tool; and the more drapable semipreg makes complex geometries easier to fill with fewer dry spots.

Although he says they’re still working out the upper and lower threshold of process parameters, Starkey adds that the system’s low forming pressures give his team a lot of freedom regarding tool substrate selection and this, in turn, has led to “a lot of novel ideas besides how to physically form the parts.”

“We wanted to be able to maintain the same level of material performance our SPRINT CBS product is known for while reducing cost and labor content, and increasing our manufacturing capacity,” Starkey sums up. “We’ve stripped away a lot of manual processing,” he emphasizes, noting that the optimized material format reduces the degree of preforming needed to mold complex features “and delivered a net-shape part without a lot of trimming. This gives us cycle-time advantages and, therefore, access to larger-volume platforms.” Assuming a 10-minute cycle, the process should produce as many as 40,000 parts per year per tool set, a rate roughly an order of magnitude faster than current thermoset CFRP processes.

Starkey’s team developed the process on an in-house prototype press and small test-plaque tool and then took it out to the field and trialed it at a large OEM and a large-tier supplier using a full-size press and production tools. The results have been very promising. Starkey acknowledges that the costs and production speeds of CFRP panels are still impractical for conventional midsized and economy cars, but he feels the supersport and premium sectors are viable targets for the first application of the new laminate/process combination.

“The commercial question is, Will the volume [of a platform] demand this process?” Starkey notes, but adds. “All the pieces are there and this technology is ready for a commercial launch.”

Related Content

Achieving composites innovation through collaboration

Stephen Heinz, vice president of R&I for Syensqo delivered an inspirational keynote at SAMPE 2024, highlighting the significant role of composite materials in emerging technologies and encouraging broader collaboration within the manufacturing community.

Read MoreMingYang reveals 18-MW offshore wind turbine model with 140-meter-long blades

The Chinese wind turbine manufacturer surpasses its 16-MW platform, optimizes wind farm construction costs for 1-GW wind farms.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreHexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

Read MoreRead Next

Gurit CBS for the Aston Martin DBS

Out-of-autoclave process mints Class A carbon composite body panels in one-hour mold cycle.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;width=70;height=70;mode=crop)