Combining curing processes for faster part production

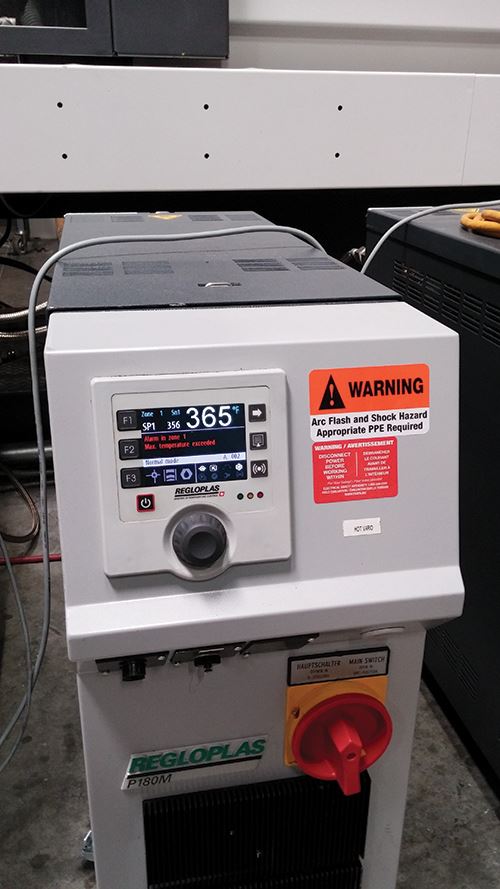

Regloplas USA (St. Joseph, Mich.) says it has demonstrated a tool heating method that overcomes poor temperature uniformity in autoclave curing processes.

A recent study by researchers from the University of British Columbia, Department of Materials Engineering, and Mitsubishi Heavy Industries, Nagoya Aerospace Systems (Nagoya, Japan), shows that airflow inside an autoclave is rarely uniform, and that heat transfer coefficient measurements made with rod calorimeters vary widely, particularly when comparing regions above and below a test tool. Despite these results, autoclaves are unlikely to be replaced at many companies because of the capital investment they represent. However, Regloplas Corp. (St. Joseph, Mich.) has demonstrated a method for overcoming poor temperature uniformity, says Kip Petrykowski, the company’s director of national sales, “and reducing autoclave cycle times, through the use of pressurized-water mold temperature controllers.”

The approach uses the vessel in concert with molds plumbed for pressurized-water heating. “Heated, pressurized water is proven as the most consistent and most energy-efficient method for heating tools, compared to air, steam, cartridge or oil heating,” Petrykowski claims. “And it’s been successfully qualified in commercial aircraft airframe part production.”

He recently conducted a study comparing conventional autoclave processing vs. water-heated tools inside the autoclave. Petrykowski used a nickel-shell plaque tool, from Weber Manufacturing Technologies Inc. (Midland, Ontario, Canada), integrally plumbed for water circulation, and a Regloplas P160M mold temperature controller to circulate hot and cool water. Thin sample parts were made with carbon/epoxy prepreg supplied by Cytec Aerospace Materials (Tempe, Ariz.), under a vacuum bag, and the tool setup was monitored via four thermocouples, a power meter and a data logger. Parts were processed inside a BondTech Corp.(Somerset, Ky.) vessel at fabricator deBotech Inc. (Mooresville, N.C.). Petrykowski measured the energy consumed for both methods (autoclave alone, and autoclave plus mold controller).

The results were striking: The autoclave alone consumed nearly 90 kW of energy over a 75-minute cure period, about 20 times the 4.3 kW of total energy consumed by the autoclave/heated-mold controller on the identical tool/part combination. “The greater energy use is due to heating a larger mass (the autoclave) and the reduced heat transfer value of the air/nitrogen used to heat the autoclave and mold as compared to the integrally plumbed tool with water heating,” explains Petrykowski. In addition, temperatures can be ramped up more than three times faster and temperature uniformity is more than 50 percent more precise with the water-heated mold than with the autoclave alone.

“The massive cooling capability of the pressurized water system is especially effective when applied to thick composite parts with the potential for exothermic reactions, and for rapid cycle production,” he adds. Further, heated-mold parts processed inside the autoclave showed mechanical properties as good as the autoclaved parts made without the Regloplas unit, based on coupon tests of the carbon plaques.

Petrykowski contends that existing vacuum ports on the autoclave can be readily disabled to allow for routing of the water hoses inside to the molds. And, existing metal tools can be retrofitted with plumbing to transition to heated-mold control. Notably, even composite tooling can be integrally plumbed with heating and cooling channels — a current Regloplas customer has done it, and is using the tool in production.

Related Content

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More