Composite + metal: Hollow-profile hybrid technology

LANXESS extends plastic-metal hybrids to tubular structures.

Injection overmolding has been much in the composites industry news lately, but primarily in the realm of creating hybrid composites. Shaped continuous fiber-reinforced prepregs or pre-cured composite shapes are positioned within the mold cavity and then encapsulated within a larger short-fiber-reinforced injection-molded part in such a way as to provide extra reinforcement only where needed to avoid overdesigned parts and control production costs. Almost unnoticed in this flurry of publicity is news around plastic/metal hybrid (PMH) structures — those that combine sheet-metal substructures injection overmolded with a thermoplastic composite.

The PMH category was recently expanded thanks to a new development first announced in Europe in March. Called hollow-profile hybrid (HPH) technology, the development enables the efficient use of extruded or welded tubular metal substructures in place of stamped or stamped-plus-welded sheet metal to achieve higher mechanical performance for PMH components subject to high loads. HPH technology made its North American debut April 30-May 1 at the 13th annual Automotive Engineering Plastics Conference (AutoEPCON) organized by the Society of Plastics Engineers (SPE, Bethel, CT, US) and held in the Detroit suburbs.

“Traditional” plastic-metal hybrid structures

PMH technology was initially developed around 1995 by Bayer AG (Leverkusen, Germany). The composites team and PMH technology were spun off as part of Bayer’s Chemicals and Polymers businesses in 2004 to become LANXESS Corp. (Pittsburgh, PA, US).

PMH uses a selectively perforated stamped steel or aluminum sheet-metal substructure that is placed into an injection molding tool that is, typically, selectively overmolded (that is, the metal substrate is not entirely encapsulated) with fiberglass-reinforced polyamide 6 (GR-PA 6). The resulting hybrid structure features the part designer’s choice of functional parts, including brackets, ribs, bosses and other geometries in composite on the outside. The perforations, which allow the thermoplastic composite to flow through and around the metal substructure, encourage a strong bond between both materials and enable the resulting structure to offer the best of both worlds. That is, the part benefits from the high stiffness and strength of thin-wall sheet metal, but it is stiffened and stabilized by, for example, composite ribs that prevent the metal from buckling. Additionally, the composite contributes corrosion resistance, good surface finish, lower weight and increased parts consolidation and functional integration achieved in a single step, thereby eliminating hardware, brackets and secondary operations. And because the matrix is PA 6, it also offers good and broad chemical resistance plus excellent toughness (impact strength).

PMH structures are lighter and have far fewer parts (produced in far fewer steps) than comparable sheet-metal structures with the same functionality, yet they have higher mechanicals than a discontinuous fiber-reinforced thermoplastic composite alone. This is particularly helpful in cases where space is limited, and thick wall sections are undesirable. The ability to greatly reduce part count and production steps not only reduces cost and the manufacturing footprint, but it also reduces inventory and warranty costs. And because its matrix is a thermoplastic, the hybrid structure can be separated and recycled at end of vehicle life.

Because of its recyclability and performance benefits, PMH technology has been used for many years to produce a variety of automotive components, from large assemblies like front-end modules and bumper beams to underhood components. It also has been used in nonautomotive applications, such as rollerblades, and components on scooters and small, off-road cars.

Tubular structures

As is true of any technology, PMH has a few disadvantages. First, amortization of metal and plastic tooling costs (both types are needed with this technique) is likely to necessitate application to medium- to high-volume vehicle programs. It’s too costly for niche production unless tooling costs can be shared with similar models on the same platform. Second, as conventionally applied, PMH technology is best used with simple 2D or 2.5D sheet-metal substructures, e.g., L-, C-shaped or flatter sections. However, those structures often lack sufficient torsional strength to meet certain high-performance requirements. Also, it’s not possible to make closed-form/tubular structures (think O-section and other tubular or square cross sections) via PMH because a closed profile would collapse under the high pressures of injection molding.

“The idea for hollow-profile hybrid structures evolved from a list of high-load structural automotive applications, where it was highly desirable to reduce mass and add functional integration, but where current PMH technology wasn’t strong enough to meet performance requirements,” explains Joseph Aiello, LANXESS structural application development engineer. He cites the cross-car beam as a theoretically ideal HPH component, since it’s heavy and contains a multitude of brackets and other attachments in metal. Cross-car beams are used on every passenger vehicle to provide torsional rigidity to the chassis. They also provide attachment points for components that penetrate from the engine compartment into the vehicle interior (e.g., steering wheels) and for components that attach from points in front of the firewall and project into the passenger cabin (e.g., instrument panels and center consoles). Prior work applying PMH technology to a cross-car beam lacked sufficient mechanical performance because the effort centered around an attempt to create the tubular (closed-form) metallic substructures for the beam by welding two open, L-shaped PMH structures together after they were overmolded. “Since a closed-form structure is well known in engineering to be stronger than an open structure, a logical place to start increasing the mechanical performance of plastic-metal hybrids was to find a way to apply the technology to hollow beams or tubes with round or rectangular cross-sections,” adds Aiello.

The challenge, as always, was to achieve a high-strength bond between the metallic substructure and any composite functional component that was overmolded onto it — a feature particularly important for structure-critical components like cross-car beams. Initially, the team worked on a technology that was suitable for overmolding standard tubes without the need for special equipment. The question became how to selectively deform the tube — create dimples or depressions — in the injection molding machine that would ensure a good interlock between the metal tube and the matrix, and thus achieve high bond strength between the metallic substructure and overmolded composite without causing the tube to collapse at the high pressures typically seen during the molding cycle. After much study, the same LANXESS team that initially developed PMH technology also developed the HPH process.

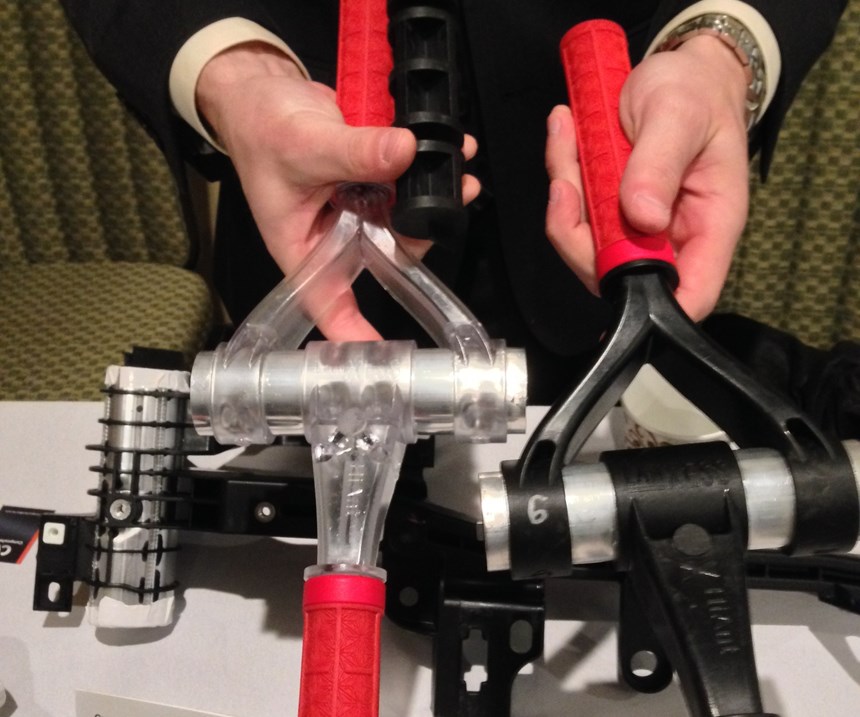

Basically, HPH uses high-flow, highly glass-reinforced PA 6 “structural elements” — injection molded solid tubes with specially designed ribs/fins projecting off the outside — that are placed into the hollow center of a steel or aluminum tube that is, in turn, inserted into an injection molding machine and overmolded with additional GR-PA 6 composite to form external bracketry and other functional components. The structural elements — which are inserted into a tube before that tube is placed into the press for overmolding — prevent tube collapse during molding and help shape/deform the tube via a process called beading or dimpling, during the high-pressure molding process, thereby assuring a strong bond between metallic and composite materials. This internal element remains in the tube to add structural support.

LANXESS reports that the internal ribbed/finned elements can even be designed to be used with perforated steel or aluminum tubes. These function like the perforations used in conventional PMH technology.

To eliminate the need for a second mold, that tool can be designed to include space in a side cavity to mold structural elements for tubes to be used in the next shot while it overmolds a given tube reinforced with structural elements. And the whole process reportedly can be fully automated, if desired.

Compared with conventional PMH structures, with stamped or stamped-plus-welded substructures, HPH structures are said to offer higher torsional stiffness and strength and better dimensional stability at comparable cross-section, mass and thickness, yet they still provide all the classic benefits of LANXESS’ original PMH process.

What’s next?

Target HPH applications include hybrid composite/metal structures with high mechanical demands that include not only cross-car beams but also car seat frames and front-end modules, truck tailgates and mirror brackets. Outside the automotive arena, it could be used to produce furniture, ladders or even baby strollers. Too new to have established commercial applications yet, HPH is said to be a part of many developmental projects in the works and LANXESS says it continues to evaluate opportunities, and reports it is still working on some technology releases to complete its patent application, which will be submitted later this year.

What might be next for HPH? LANXESS also says it has previously done PMH research using PA 6/6 and polybutylene terephthalate (PBT) matrices and carbon fiber reinforcement, and even has evaluated magnesium substructures, although the vast majority of commercial applications remain in GR-PA 6 with glass loading levels of 30-60%. Theoretically the same material combinations could be used for HPH, although the team’s focus remains on 60% GR-PA 6. If carbon fiber reinforcement was used, metal substructures would need to be isolated (likely via a coating) to prevent galvanic corrosion. Or, for less structural applications, it should be possible to use a tube extruded or pultruded from a plastic or composite.

Related Content

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;width=70;height=70;mode=crop)