When architecture firm Steinlia AS (Oslo, Norway) was commissioned to design a second-floor addition to an existing apartment complex in a historic district in London, U.K., architect Matthew Anderson explains that there were a number of challenges involved. The structure not only needed to meet building codes and structural requirements, he says, but also needed to be lightweight to meet weight requirements for crane installation, constructed and installed quickly at a site with restricted access and match the complex geometry of the existing house.

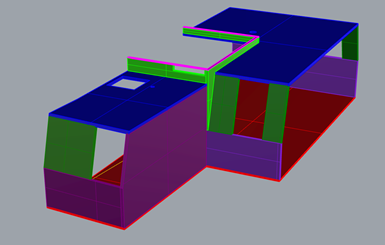

To meet these requirements, Anderson designed a prefabricated, two-pod concept largely comprising lightweight composite sandwich panels engineered by vdL Composites (Wesel, Germany), a joint venture formed in 2012 by ATL Composites (Molendinar, Australia) and MuH von der Linden (Wesel, Germany) to produce DuFLEX composite panels for the European market.

DuFLEX panels are used for the main structure of the extension, including the 70-millimeter-thick external walls and roof and 40-millimeter-thick floor. As the panels also offer appropriate insulation, they also serve as the finished internal surfaces for the walls, ceiling and floor.

The structures are constructed from 600-gsm biaxial E-glass/epoxy skins from ATL Composites, cored with PET foam. “We chose DuFLEX due to its high specific strength [strength/weight ratio], insulating properties, aesthetic qualities and flexible application,” Anderson says. The PET foam was chosen for its recyclability, smoke and toxicity properties, good mechanical performance, chemical stability and its tendency not to absorb water.

Interior of finishing housing unit. Photo Credit: Agnese Sanvito

DuFLEX composite panels are said to offer a range of benefits, including structural stiffness and light weight — a 90% weight saving over a comparable steel design, according to vdL Composites. They are also said to be durable and low maintenance, and will not rust, rot or corrode. DuFLEX is also reported to provide excellent thermal insulation with vastly improved properties compared to steel, with a significant reduction in the size and weight demands on support structures and foundations; this is also said to translate to a reduced cost for installation and handling. With diverse applications ranging from building facades and doors, gates and window frames, to long-span roofing, composite decks, bridges and pre-fabricated housing, DuFLEX can be engineered into a majority of architectural projects to meet design loadings and regulatory requirements.

For this specific project, the pod sections were built and CNC routed at vdL Composites’ Germany facility, and then glued together and packed at Bootswerft Baumgart, a shipyard in Dortmund, Germany. From there, they were transported by Glogau International Yachttransporte (Neumünster, Germany) to the London site.

Exterior of finished housing unit. Photo Credit: Agnese Sanvito

The project began in September 2019 and was completed in July 2020, including a two-month delay due to COVID-19 restrictions. The pods themselves were installed in only two hours, according to Anderson. “We are satisfied with both the speed and precision of constructing with DuFLEX, the structural performance of DuFLEX and the beautiful rooms that we created together,” he adds.

Related Content

-

Bioabsorbable and degradable glass fibers, compostable composite parts

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.

-

Composite wrap system combats corrosion in industrial tank repair

A fiberglass and carbon fiber composite wrap system enabled an Australian nickel mine to quickly repair a stainless steel ammonium sulphate feed tank and protect against future corrosion.

-

ZEBRA project demonstrates closed-loop wind recycling system

Consortium partners have proven the complete recycling of thermoplastic wind turbines via two manufactured wind blades, featuring reduced operating cost, CO2 emissions.

.jpg;width=70;height=70;mode=crop)