The calligraphy and stainless steel-clad exterior of Dubai’s Museum of the Future comprises 17,000 m2 of composite panels made using 1,000,000 m2 of fire-retardant glass and carbon fiber-reinforced epoxy prepreg. Source | CW

The Museum of the Future currently being constructed in Dubai, United Arab Emirates (UAE), is one of the most complex structures ever built. The 78-meter high building houses seven floors within a torus-shaped shell that sits atop a three-story podium. The exterior facade of the torus comprises 1,024 fire-retardant (FR) composite panels. Clad with stainless steel, each panel is a unique 3D shape and integrates molded-in Arabic calligraphy. The flowing script forms poems that describe the vision for Dubai’s future by His Highness Sheikh Mohammed bin Rashid Al Maktoum, vice president and prime minister of the UAE and ruler of the Emirate of Dubai. They also serve as the building’s windows, casting daylight through the column-free interior and creating a dramatic effect at night via 14 kilometers of integrated LED lighting.

Conceived by Sheikh Mohammed as an incubator for innovation and invention, the Museum of the Future is considered to be one of the most advanced buildings in the world, a place where people can experience and research new technologies. It is also a symbol of architecture that pushes boundaries via digital design and use of more efficient materials. Parametric design was used to develop the steel diagrid — a framework of 2,400 diagonally intersecting steel members — to which composite concrete floor slabs and 17,000 square meters of composite cladding are attached, the latter using 1 million square meters of multiaxial glass and carbon fiber-reinforced epoxy prepreg.

Dubai firm Affan Innovative Structures provided the composite design for the panels, as well as fabrication and support for installation. “This is the first time such a project has been undertaken,” says the company’s CEO, Dr. Amer Affan. “And also the first time composite panels have been used to integrate multiple building functions via such complex shapes.”

Integrated LED lighting. Recesses in the composite facade panels house not only the Museum of the Future’s windows but also LED lights, illuminating the calligraphy script at night. Source | Affan Innovative Structures

Principal architect Shaun Killa explains that such complex exteriors are normally rain screens, with a building behind that contains the waterproofing system. “This simplifies matters because it’s a bit more forgiving when creating these very three-dimensional forms,” he notes. “In this building, however, the envelope is doing the waterproofing, the airtightness, the structure and the lighting.” Affan concedes that for such a grand project, his company is small in size, “but we have used our technical expertise to achieve something unique and have shown how buildings will be built in the future.”

Capability in complex, digital designs

Affan Innovative Structures was initially contacted by the Museum of the Future engineering team. “There were not many companies who could do the work required for the exterior cladding,” notes Affan. “The only other competitor proposed a normal curtain wall with aluminum or stainless steel panels on the outside.” Curtain walls, typically used in addition to a structural steel framework, are thin and made from aluminum frames that support glass, metal and/or thin stone exterior panels (see “The building envelope: FRP unitized facades”). This was rejected by the engineering team as too difficult and unable to provide the same appearance as was possible using an integrated, multifunctional composite panel facade. Thus, the latter, proposed by Affan Innovative Structures, was selected for the project. “We also have unique technology that enables us to make large panels,” Affan adds, “up to 3 meters wide by 9 meters high, curved in both directions, which means fewer joints.”

Affan Innovative Structures was uniquely suited for this project. Formed in 2004 by Dr. Affan, the company provides complete turnkey solutions — from concept design to installation and building maintenance — gravitating toward very technical challenges. The company’s résumé includes the complex, geometric aluminum screen/cladding for the King Abdullah Sports City Stadium (Jeddah, Saudi Arabia), the composite entrance canopy and 64 intricately-patterned glass and steel skylights for the Yas Mall (Abu Dhabi, UAE), the exterior composite roof for the Sidra Hospital (Doha, Qatar) and many other challenging projects. This capability in complex steel, glass and composite assemblies would be exactly what was needed for the Museum of the Future’s multifunctional composite exterior.

“Within each composite panel, there is a system of flat glass [panels] inside the Arabic script,” Affan explains. “The glass is almost recessed inside of the panels, up to 200 millimeters in depth.” This recess changes not only from the building’s top, with less recess to prevent water trapping, to the bottom, where vertical and undercut panels can be deeply recessed without trapping water, but also within each panel, slanting and diminishing to produce a gradual, natural edge for the script. “The location and edges of the recess also varied per the location of the glass within the panel because the glass was flat but the panels were curved,” notes Affan. “This was only possible with digital design and CNC machining.” This precision would also be needed to ensure that the script, which varied from one panel to the next, aligned precisely as the panels were installed so that the letters and words flowed correctly across the building’s exterior.

Complex parts, CNC-machined molds

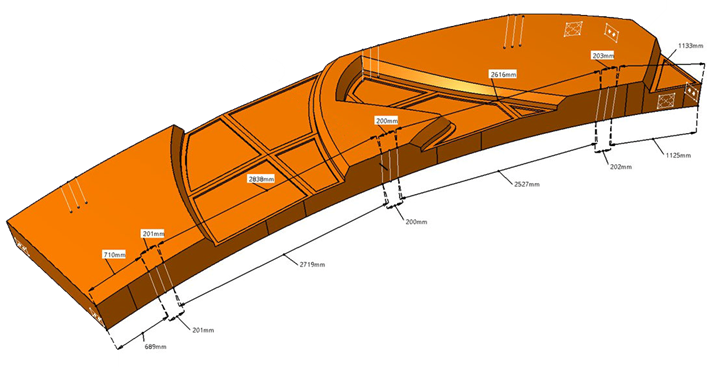

Each complex-curved facade panel was designed in CATIA to include Arabic script cutouts and varying recesses for flat glass windows, as well as “cassette” edges reinforced to support lifting during installation and attachment to the building’s steel framework. These were then translated into designs for molds CNC machined from PU foam. Source | Affan Innovative Structures

For Affan, the only solution was to mold the Arabic script and recesses into each composite panel. “Reinforcements would be laid into precisely CNC-machined molds,” he explains. Fortuitously, the CATIA software (Dassault Systèmes, Vélizy-Villacoublay, France) that Affan Innovative Solutions uses to drive its CNC machines is also the 3D CAD program used by the aerospace industry to design complex aircraft and composite structures. In addition, Affan’s team of 28 engineers are also proficient in Tekla BIM software, Rhino 3D (Robert McNeel & Assoc., Seattle, Wash., U.S.) and AutoCAD by Autodesk. “We did all of the drawings in CATIA, as well as the laminate design, which gave us the ability to do such complex machining,” says Affan.

The design, however, was not trivial, and had to meet a variety of structural and wind loads. For example, the inside of the torus created a wind tunnel effect, Affan explains. These panels must withstand up to 450 kg/m2 (92 lb/ft2) of wind load. (Note, the International Building Code lists wind loads of 71 lb/ft2 for high-risk hurricane areas in West Palm Beach, Fla., U.S.). The composite panels for the Museum of the Future are also tailored to minimize weight. “The panels use 9 to 13 plies, which vary by location and loading,” says Affan. He adds that the Composite Technology Center (Stade, Germany), an Airbus subsidiary and a long-time partner via the CFK Valley ev (Stade, Germany) trade organization, “provided a third-party check on our laminate design, deflection and stiffness calculations.”

One additional complexity, and innovation, is that the panels also integrated their own attachment system. “At the edges, 24 plies form the cassette-like attachment geometry to connect to the building,” Affan explains. A cassette system is a method for attaching external cladding, originally developed for rain screen-type installations. Though types and geometries vary, cassettes typically enable a flat, rainproof exterior surface that is secured behind to the building’s load-bearing framework. For the Museum of the Future’s facade panels, separate pieces were not required to form the cassette edges, but instead were machined into each mold and thus integrated into each composite panel.

Materials, molds and panel manufacturing

Even though Affan Innovative Structures’ 10,000 square meters of composite fabrication space has 16 resin infusion machines and eight glass-topped, steel-based resin infusion tables measuring 3 meters by 20 meters, it chose to use prepreg. Why? “Achieving the necessary FR performance requires a lot of additives, so the resin becomes thick and won’t flow in infusion,” Affan explains. In this case, the additive was aluminum trihydrate (ATH, see “Withstanding fire without the weight”). He continues, “Thus, we worked with Notus Composites [Ras Al Khaimah, UAE] to develop an FR epoxy prepreg. We primarily used glass fiber but also carbon fiber in certain sections where there were deflection issues.” Approved by the Dubai Civil Defense, Notus Composites EPFR-609 prepreg, in combination with NE11-FR surface film, has passed NFPA 285, EN13051-1 and ASTM E1098 and E84 Class A fire requirements (see “Fire-retardant prepregs enable ...” and “Better, cheaper screening of FRP building materials”).

Because external metal surfaces in Dubai can reach temperatures of 80°C (176°F) in summer, Affan explains, “we cured the prepreg at 120°C to ensure sufficient Tg (glass transition temperature) to resist head deflection. Thus, the molds were machined out of a polyurethane foam which could withstand that high temperature, which is more expensive. We tried three or four different foams, but only one could withstand the temperature plus vacuum pressure, and yet was soft enough to CNC machine easily and quickly.

CNC machining of each mold took 12 to 72 hours and each of the 1,024 composite panels required its own mold. All four of Affan Innovative Structures’ CMS (Zogno, Italy) 5-axis CNC machines — the largest measuring 33 meters long by 13 meters high by 2.5 meters high — were needed to meet the museum’s demanding production rate. “If one [machine] was down for maintenance, we had the others running in parallel,” Affan explains.

Prepreg plies were cut and kitted using a (Bulmer, Mehrstetten, Germany) automated cutter. “We did not use core in the panels because, unlike today, there were no foam cores at that time that could pass the FR requirements,” says Affan. Even with such automation, the company’s workforce of 250 employees, a total it had reached by 2015, were also necessary to deliver on production, averaging four panels per day. Teams of six workers, each with a supervisor and balanced set of skills to be efficient, laid up the panels. “Normally, we’d have two or three teams working on a project,” Affan notes, “but to meet this production schedule we had 20 teams working at any given time.”

Manufacturing Steps

Layups were hand laid, vacuum bagged and cured for 6 hours in ovens that measured 20 meters long by 8 meters wide by 3 meters high. “Each CNC machine had its own oven,” says Affan. “We did not bunch many panels together per cure cycle. Instead, when each panel was ready, we immediately cured it to maintain as high a production flow as possible. We then demolded the panels and used a 3D scanner to ensure the as-made panel matched the CATIA file. Per our total quality control system, we had to check against the digital files at every single step in the process.”

Finished panels then received the stainless steel exterior finish. “The stainless steel is adhesively bonded to each panel and then attached with mechanical fasteners, which is an art in itself,” says Affan. “The metal was cut into small hexagons in order to drape over the 3D panels. The hexagonal grid varied part to part depending on the amount of curvature. Even though we have experience and confidence in bonding, there could be no risk of a single hexagon coming apart during the lifetime of the building. Thus, every single hexagon had to be attached — requiring as many as 200 to 300 attachments for a single panel.” Finished panels were then sent to site to be installed.

NASA-aided, issue-free installation

Installation was actually completed by the building’s construction firm BAM International (Gouda, Netherlands). “We only supplied supervisors for installation to help with how to handle the panels,” notes Affan. “The way each is lifted is key. The panels were designed to be strong enough for each one’s specific position in the building. However, they must be lifted in a specific way, via at least two lift points, just like hanging cassettes in more traditional building methods.”

There was an additional issue that Affan was uniquely qualified to solve. “In order for each panel to sit on the steel structure and yet form the smooth surface, we needed the ability to adjust the panel in depth, orientation and curvature in 3D — in other words, a kind of universal joint with three degrees of freedom. In 1985, I worked as a student at NASA in California on damping of space station structures. The key was to be able to move each structure and adjust it when the shuttle docks so that vibration is damped quickly, a bit like noise cancellation. I used the same technology for the panel attachment and adjustment during installation.”

Also, because the panels were providing the building’s watertight seal as well, there could not be gaps between them. “The panels could not abut directly, or they could crack,” says Affan, explaining that due to a high live load of 1.5 tons on the cantilevered 6th floor exhibition area, the steel structure actually moves. “We maintained a precisely spaced gap between panels and this was filled with a special gasket.” This gasket, soft enough to expand, yet rigid enough to withstand loading, provided sealing functionality while enabling the building’s aesthetic appearance.

Such solutions are an advantage, Affan notes. “Because we come from a structures background, we are able to combine many materials. This is very important. Composites are just one material we use. This was not just a composite project.” The results speak for themselves. “The installation went well; there were no issues at all,” says Affan, who notes there was no way to check if the panel would fit except to ensure its conformance to the digital file. “We haven’t had a panel yet that has not fitted or has been the wrong shape or the word misspelt,” testified Buro Happold project manager Bauly in a BBC article by Elizabeth Bains.

Future modular construction

“We managed the whole process together,” adds Affan. “Teamwork within our company itself was also key; design and layup groups had to coordinate with each other. We’ve never done a job as big as this, and it was a challenge, but we like challenges.”

Unfortunately, COVID-19 has taken its toll. “We finished this job just before the pandemic lockdown,” he says. “Now, we are down to less than 30 people. It’s devastating. But this has affected everyone, not just us.” And yet, Affan sees hope for the future and for the role composites will play in achieving the sustainability and innovation the world needs in construction. “Especially in Dubai and the GCC (Gulf Cooperation Council), people want to try new ideas. It is demonstrating the future of architecture and construction.”

“The future belongs to those who can imagine it, design it, and execute it. While others try to predict the future, we create it.”— Sheikh Mohammed bin Rashid Al Maktoum

That future, he emphasizes, will be for those who can use modular systems of construction, “and COVID-19 is actually accelerating this. Companies will build in modules and send those to the site. This will develop because it moves inefficiencies off-site and into a factory, increasing control and quality. On-site, you have to coordinate all of the people. It wastes time, waiting for other subcontractors. You are also dependent on the weather and work stoppages. Fabrication in a factory eliminates all of this. Because they are strong, light and durable enough to transport and install easily, composites allow this type of modular construction and you can make any shapes you want.”

Affan notes that modular construction has been used in cruise ships for years, where each cabin is premade, complete with heating/air conditioning, electrical and plumbing systems, and then assembled into the ship’s steel framework like LEGO blocks. “Imagine how much time you will save when each module is already outfitted. We are looking now at a project to make a high-rise building in this way using composites,” he says. “If you have FR resins, then you don’t need the parts that were previously metal.” Citing a Marriott hotel built this way and completed last year in New York City, Affan adds, “that building was steel and timber, but we can build it in composites.”

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreRead Next

FRP sunshades developed for San Francisco retrofit

The 53-year-old office building possesses about 680 FRP hoods, which improve poor daylighting.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More