Composite pressure vessels take on cryogenic temperatures

Several recent innovations involving composite high pressure tanks indicate a leap forward in pressure vessel technology.

A race seems to be underway to develop stronger, lighter and more cost effective pressure vessels that can withstand the extremely cold temperatures of rocket fuels. In the past, using composites for the storage of cryogenic liquid fuel – liquid hydrogen, liquid oxygen, liquid methane – has been met with concern revolving around the potential for leaks, due to microcracking of traditional carbon/epoxy composite laminates at extremely low temperatures. A leap forward with the technology seems to be underway.

In July it was reported that Ingersoll Machine Tools (Rockford, IL, US) has created the world’s largest fiber placement machine – 51 feet tall, 136 feet long and 43 feet wide – for Blue Origin (Kent, WA, US) that will be used to manufacture composite cryogenic rocket fuel tanks as well as payload fairings.

In early October, CW senior editor Sara Black blogged on a liner-less carbon fiber-reinforced composite tank developed by Cimarron Composites (Huntsville, AL, US). The company says the pressure vessel has achieved a 15,000 micro-strain performance, which is reportedly around five times the amount of pressure such vessels were previously limited to.

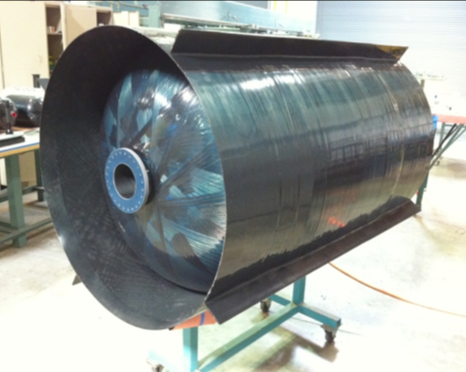

Recently Scorpius Space Launch Company (SSLC, Torrance, CA, US) unveiled carbon fiber cryogenic high pressure tanks with anti-slosh baffles integrated to the interior walls of propellant tanks. The design aims at enabling rockets using propellant tanks as load bearing elements and even as primary structures. According to Markus Ruffer of SSLC, the company’s tanks can incorporate features such as baffles, fins or stringers in a mechanical way without relying on adhesives. All parts of the Type V tank are made of the same materials – carbon fiber and a proprietary resin system – thereby eliminating dissimilarities in properties and the coefficient of thermal expansion (CTE) within the tank. The approach yields a robust tank – SSLC’s vessels can hold up to several thousand psi pressure and are qualified for a temperature range of -320°F to +170°F.

Where will the technology lead next? One can only guess, but the indication seems to be that we’ll see more and more liner-less vessels with thinner walls.

Related Content

-

Henkel receives Airbus qualification for European aerospace manufacturing facility

The adhesive company’s Montornès, Spain, plant has been approved as a standard and raw materials supplier for various Airbus platforms, adding to its work in lightweighting, fuel efficiency and automation.

-

BiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.

-

Belzona composite wrap restores corroded carbon steel pipeline

Two-part epoxy paste, epoxy structural adhesive, composite wrap and anti-corrosion coating prevent environmental and economic loss for customer.