Composite solutions: Cutting cost of nuclear-powered subs

Composite-for-metal substitutions cut expense, boost production for Virginia-class submarine program.

Engineering Challenge:

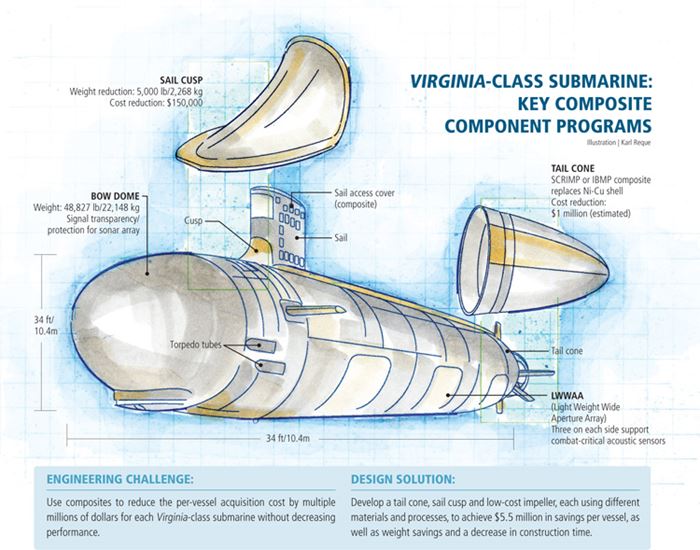

Use composites to reduce the per-vessel acquisition cost by multiple millions of dollars for each Virginia-class submarine without decreasing performance.

Design Solution:

Develop a tail cone, sail cusp and low-cost impeller, each using different materials and processes, to achieve $5.5 million in savings per vessel, as well as weight savings and a decrease in construction time.

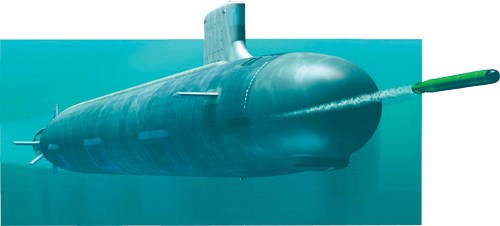

Touted by the U.S. Department of Defense (DoD) as the most advanced submarine in the world, the Virginia-class is the newest addition to U.S. Navy’s nuclear-powered fleet. Measuring 377 ft/115m in length, 34 ft/10.4m in diameter, a Virginia-class submarine (VCS) can exceed 25 knots underwater and can remain submerged for three months. When the class namesake, the USS Virginia (SSN-774), was launched in 2004, however, its $3.2 billion (USD) price tag exceeded, by far, the estimated unit acquisition cost for the planned fleet of 30-plus boats. When construction began in fiscal year (FY) 2005 on a second vessel, the USS Missouri (SSN 780), only $2.4 billion was budgeted. But the chief of naval operations, Admiral Mike Mullen, challenged the program partners to reduce the future acquisition cost by an additional 20 percent as a condition for increasing production from one to two vessels per year, starting in FY2012. Thus began a cost-reduction program, targeting a per-vessel acquisition cost of $2 billion (all figures in 2005 dollars). According to Robert Hamilton, director of communications for prime contractor General Dynamics Electric Boat (Groton, Conn.), composites have played a key role in efforts to reach that goal.

Hamilton explains that Electric Boat and major subcontractor Northrop Grumman Shipbuilding-Newport News (now Huntington Ingalls Industry-Newport News, HII-NN, Newport News, Va.) worked closely with the South Carolina Research Authority (SCRA, Columbia, S.C.) through the latter’s Composites Manufacturing Technical Center (CMTC) in Anderson, S.C. (see “SCRA, composites and the U.S. Navy” under "Editor's Picks," at top right). SCRA managed three composite applications for the VCS cost-reduction program — the tail cone, the sail cusp and the impeller (see drawing) — which were developed through Office of Naval Research (ONR) Manufacturing Technology (ManTech) programs. SCRA expects a $5.5 million reduction per hull when all three are introduced. Jonathan Osborn, SCRA’s project manager for the three programs, says they “have provided one of the best returns on investment for the CMTC and are really a tremendous success story.”

Composite tail cone

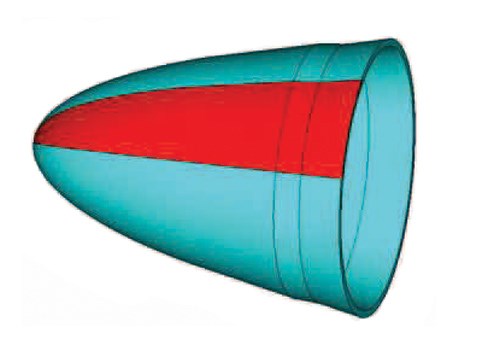

The existing nickel-copper metallic shell for the tail cone is expensive in terms of materials and manufacturing methods. ManTech’s objective was to reduce the cost by an estimated $1 million, using a composite tail cone that would be connected to the propeller hub via a forward metallic interface ring. The program evaluated multiple composite processes. “We looked at a filament-wound tail cone as well as SCRIMP [Seemann Composites Resin Infusion Manufacturing Process] and … the Integrated Bleeding/Breathing Manufacturing Process, or IBMP,” Osborn recalls. IBMP uses a dry fabric with a thin resin film applied to one side and is vacuum bagged and oven cured. Osborn explains that this material and process, “allows air to breathe out of the laminate during cure and [allows] resin to bleed into the dry fabric, hence the use of both Bleed and Breathe interchangeably to explain the acronym.”

“Filament winding was explored,” says Osborn, “because two tail cones could be wound at once, but the shape did not exactly lend itself to winding and, overall, did not produce desired program results.” However, both the SCRIMP and IBMP parts were successful. Seemann Composites (Gulfport, Miss.) produced the SCRIMP tail cone, and Goodrich Engineered Polymer Products (Goodrich EPP, Jacksonville, Fla.) produced one using IBMP, for which Osborn’s team specified SPRINT material from SP-High Modulus, the marine business of Gurit (Isle of Wight, U.K.). Other tail cone team members included Triumph Aerospace (Newport News, Va.) and the Applied Research Laboratory at Penn State University (State College, Pa.), a DoD-designated U.S. Navy University Affiliated Research Center.

According to Osborn, the Naval Surface Warfare Center (NSWC) Carderock Div. designed the composite tail cone and has authorization to install it on the ninth VCS, the USS Mississippi, to be launched later this year. This will be the first composite tail cone used on a U.S. Navy submarine.

Composite sail cusp

The sail cusp is a hydrodynamic fairing between the hull and the lower leading edge of the submarine sail (the vertical fin on top of the hull). The original cusp was made from numerous steel components with stiffeners, fitted together and welded, then filled with syntactic foam to inhibit corrosion and, finally, welded to the sail and hull structures. This method was material- and labor-intensive due to the sail cusp’s complex double curvature and the number of parts required to fit and attach the cusp to the hull. Because the steel cusp was welded in place, it was not readily removable for maintenance. The composite sail cusp offers a corrosion-resistant, syntactic-filled structure, with inner and outer composite skins bolted to the sail and hull.

Osborn says that ManTech team members for the sail cusp were roughly the same as for the tail cone. Evaluation sail cusps were made via SCRIMP/VARTM (vacuum-assisted resin transfer molding) by Seemann Composites, and via IBMP by Triumph Aerospace. Although both processes reduce cost, and although Electric Boat maintains material specifications for both, Goodrich EPP was awarded the supply contract by Triumph, which procured the composite sail cusp design by Electric Boat. The cusp is said to be 5,000 lb/2,268 kg lighter and $150,000 less expensive than the steel version, achieves a schedule reduction from 14 months to 3 months, and an estimated $20,000 savings per periodic VCS sail maintenance.

Low-cost composite impeller

The third component is a composite centrifugal pump impeller (a vaned, rotating disk which forces fluid in one direction under presssure). It replaces a tight-tolerance part cut from a large forged ingot of titanium by 5-axis machining. The high material cost was escalating and volatile; the machining process was very expensive, complex and generated a lot of waste. The ManTech objective was a low-cost composite alternative with no reduction in performance. Osborn explains, “When we moved to composite, we were able to net-shape fabricate, using a mold without additional machining.” Impeller parts wee resin transfer molded using carbon- and glass-fiber reinforcements with vinyl ester resin, which were then assembled and overwrapped with filament-wound fiberglass. The program reduced part cost by roughly $550,000 per submarine and shortened its build schedule from nine to three months. It has also led to a more complex impeller development program, slated for implementation on the VCS as well.

Other VCS composites

Goodrich EPP supplies the bow dome, a 48,827-lb/22,148-kg hydrodynamically shaped composite structure that houses and protects the sonar array, as well as composite towed array fairings, the high-frequency sonar chin array and pylon fairings. Seemann Composites also builds composite parts for the VCS, including a snorkel fairing, sail access covers, strainer plates, flood grates and Light Weight Wide Aperture Array (LWWAA). The LWWAA consists of large, complex curved composite structures, which support acoustic sensors that feed into the submarine’s combat system. Each LWWAA unit includes fairings and an array support plate, giving the appearance of an elongated blister on the hull exterior. Three units are mounted on each side of the submarine. A ManTech FY2011 program is reducing the machining cost by developing an automated machining process specifically adapted to their complex curvatures, thickness variations and weights.

A similar project will evaluate options for replacing current metal sail deck gratings, perforated universal modular mast (UMM) cableway foundation plates, and angle-bar foundation plates with composite alternatives that will significantly reduce corrosion-related maintenance costs over the vessel’s expected 33-year service life.

Future submarine composites

Noting that “it is easier to maximize the benefits of composites by considering them in the beginning vs. waiting until later in the process,” Electric Boat’s Hamilton says his company is looking at what role composites can play in the Navy’s coming replacement for its aging Ohio-class ballistic missile submarines (SSBNs). The DoD recently approved the Ohio Replacement Program’s entry into the Technology Development Phase and endorsed a proposal to replace the 14 current Ohio-class subs with 12 new 560 ft/170.7m long, 43 ft/13.1m diameter vessels, targeting 2019 for lead ship construction. Based on Virginia-class successes, composite structures are likely to be important in achieving the recently announced reduced cost goal of $4.9 billion for the Ohio-class replacement.

Related Content

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreFarnborough Airshow 2024 brings together aerospace innovation, collaboration

The week-long international airshow provided a hub for new announcements made by Boom Supersonic, Airbus, Boeing, GKN, GE, ZeroAvia, Eve, Bell, VoltAero, Eve and Lilium. CW has compiled several below.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreHypersonix receives CMC scramjet manufacturing demonstrator

HTCMC component demonstrates manufacturing of future Spartan scramjet engine required for reusable hypersonic vehicles capable of up to Mach 12 flight.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More