COMPOSITES 2011 Product Showcase

Composite Technology magazine's review of the goings-on at COMPOSITES 2011, this year’s edition of the American Composites Manufacturers Assn.’s (ACMA, Arlington, Va.) annual trade show and conference (Feb. 2-4, Greater Ft. Lauderdale Convention Center, Fla.).

COMPOSITES 2011, this year’s edition of the American Composites Manufacturers Assn.’s (ACMA, Arlington, Va.) annual trade show and conference, marked the show’s return to Ft. Lauderdale, Fla. (Feb. 2-4, Greater Ft. Lauderdale Convention Center). Among the show highlights was the latest in ACMA’s string of high-profile keynote speakers. Last year’s outing by U.S. 2012 presidential hopeful Mitt Romney was followed this year by the former commander of U.S. and International Forces in Afghanistan and retired U.S. Army General Stanley McChrystal (ret.). For a summary of his remarks, follow the "COMPOSITES 2011 keynoter" link listed in “Editor's Picks,” at top right, or finish reading this article and find the summary at the bottom of this page.

The ACMA also announced the 2011 winners of the Awards for Composites Excellence (ACE). Best of Show went to Corrosion Companies Inc. (Washougal, Wash.) for its Composite Cargo Tanker, designed to handle ground transport of corrosive liquids. It features a filament-wound composite tank with a core of BALTEK SB 100 balsa, from Baltek Inc. (Northvale, N.J.), a 3A Composites company. The tank’s inner liner features the first DuraShield carbon fiber continuity system for checking liner integrity.

Callaway Golf Co. (Carlsbad, Calif.) took home the Most Creative Application award for its RAZR Hawk Driver, the first Callaway driver equipped with the company’s Forged Composite aft body, made using a carbon fiber-reinforced molding compound and a proprietary compression molding process. Reportedly parts are strong, lightweight and precise, with good surface finish and a wall thickness as small as 0.035 inches/0.9 mm.

The Process Innovation honors were Italpresse/Acell USA’s (Punta Gorda, Fla.) for its Acell Monolithic Composite Process, which molds composite sandwich panels in a single pressing operation (see Italpresse item on p. 22).

Continental Structural Plastics (CSP, Troy, Mich.) collected the Composites Sustainability Award for the cover assembly on the 2011 Chevrolet Volt’s rechargeable 220-cell lithium-ion battery pack. The combination of patented, lightweight structural SMC formulations and proprietary molding and manufacturing processes developed by CSP helped General Motors (Detroit, Mich.) develop the low-cost, low-mass and chemical-resistant cover.

The award for Equipment Innovation was captured by MD Fibertech Corp. (Sausalito, Calif.) for its Multi-Directional (MD) reinforcement system, a high-speed (600 m/hr) production process that uses unidirectional (UD) reinforcements as feedstock to produce high-quality, low-weight multidirectional reinforcements. MD reinforcements are suitable for applications in the wind-energy, automotive, marine, aerospace, transportation and military/defense sectors. One MD production machine reportedly can produce the same output as 6 to 30 competitive machines.

The Infinite Possibility for Market Growth Award was given to GASTANK SWEDEN (Pitea, Sweden) for its glass-fiber composite Type IV compressed natural gas (CNG) tank. It is the first fully wrapped glass-composite cylinder that meets requirements set forth by the R110 United Nations standards for implementation of this equipment on ground transport vehicles. The fiberglass cylinder is 57 percent lighter than a comparably sized steel cylinder with similar pressure capacity.

Finally, 3B - The Fibreglass Co. (Battice, Belgium) was recognized for Innovation in Green Composites Design in its water and sewer applications, including manholes and trapdoors. Parts are made of minimum 90 percent recycled materials and 55 percent glass fiber waste.

On the ACMA show floor

Akzo Nobel (Amsterdam, The Netherlands) touted its reportedly underused Trigonox 524 line of organic peroxides catalysts. Brought to market eight years ago, Trigonox 524 is designed for use in resin transfer molding (RTM) and filament winding applications and reportedly features good styrene-reduction capabilities. The company’s own tests of 4-mm/0.16-inch laminates cured at 80°C/176°F showed residual styrene of less than 0.1 percent. Further, gel time in pure resin at 20°C/68°F is almost 30 minutes, with time to peak exotherm (119°C/246°F ) of less than 5 minutes. This material’s potential to aid molding of Class A surfaces makes it suitable for use in automotive interiors, say company representatives.

In its booth, Bayer MaterialScience (Pittsburgh, Pa.) featured several applications pultruded with its Baydur polyurethane. Among them was the GThurm line of polyurethane window lineals. The first commercial installation of GThurm windows took place in late 2010 at the Bayer CropScience LP Development and Training Facility (Clayton, N.C., see photo at right). Manufactured by Graham Architectural Products (York, Pa.), the windows are expected to realize energy savings of roughly 12 percent. They are the first American-made, architecture-rated windows to feature thermal transmission values as low as U 0.18 (R 5.5), using readily available insulating glass. GThurm windows feature Graham glass-reinforced polyurethane (G2RP) technology, consisting of 80 percent continuous-strand glass combined with 20 percent resin.

First-time exhibitor Biesse America Inc. (Charlotte, N.C.), the U.S. sales arm of a CNC machining and trimming equipment manufacturer based in Pesaro, Italy, reported on recently completed work at a new facility in Montreal, Quebec, Canada, and enhanced operations at its outlets in Toronto and Charlotte. All three locations now feature working displays of its CNC-machining cells.

CCP - Cook Composites & Polymers (Kansas City, Mo.) emphasized its ENVIROGUARD resins line. Designed for laminating, infusion, casting, compression forming, pultrusion and cured-in-place processes, they feature renewable content in volumes ranging from 12 percent to 39 percent. The company says the resin line offers physical properties similar to conventional resin systems, as well as comparable chemical and UV-resistance.

Eastman Machine Co. (Buffalo, N.Y.) introduced its new Power Roll Stand, engineered to feed rolled material goods onto the company’s line of fully automated, conveyor cutting systems. The stand features an ultrasonic beam that monitors the roll diameter to control feeding speed and, thus, reduce the stretching that can distort the material or, in the case of fabrics, alter yarn alignment. It can handle rolls up to 2,000 lb/907 kg and roll widths up to 48 inches/122 cm.

Distributor E.T. Horn (La Mirada, Calif.) displayed Basfiber basalt fiber products from Kamenny Vek (Dubna, Russia). Reinforcement forms include roving and twisted yarn, chopped strand, fabrics, reinforcing mesh and nonwoven forms.

Distributor Fiberlay (Seattle, Wash.) showcased its new DraGun (pat. pend.) high-precision metering pump that can be driven cost-effectively by a common, ½-inch electric hand drill or a few select ½-inch portable battery drills. Available in 1:1, 2:1 or 4:1 drive ratios, the pump is an axial-piston type, driven by a gear that replaces the ½-inch chuck on the drill. It can pump epoxy, polyurethane or other products of 1000-cps or less viscosity from pails or drums, and can pump thicker material with an optional pressure tank.

Gibson Fiberglass/Jushi USA (Irwindale, Calif.), the result of a merger of Jushi Group and Gibson Fiberglass, highlighted its ViPro, a new high-strength/high-modulus glass fiber aimed at composites applications that require better corrosion resistance and enhanced physical properties (e.g., wind turbine blades and high-pressure pipe). Currently produced in trial quantities, the fiber is being tested by a group of Gibson customers. Commercialization is expected by the first-quarter 2011.

Dust and fume ventilation specialist Frees Inc. (Shreveport, La.) highlighted its new Direct Digital Control system, an “intelligent” product that senses the presence of styrene emissions in a workspace and ventilates the area accordingly. The system also cycles the equipment off or reduces operation to minimum levels when styrene emissions subside. The control features a Web-based interface and provides remote access for troubleshooting by Frees, when necessary. Also new from this company is an energy-recovery system that reclaims energy from heated or cooled exhaust air and transfers it to the incoming outside air to maintain a temperature setpoint for the factory floor.

Cutting table manufacturer Gunnar USA (Arlington, Wash.) touted the versatility of its suite of three nesting and cutting modules. The first module, Wingman TTC Cutter Control Software, enables users to import files from a nesting program or directly from a CAD program. Compatible with most CAD file types it also accepts machine code files from some competing manufacturers, including Gerber and Lectra. The second module, CAMsuite Nesting Extension Package, offers manual and automated nesting and enables the user to lay out fabric shapes and designs on the cutting table to minimize waste. The third module, ERP Interface, reads orders from an existing ERP suite, then stores and manages them through the cutting process. www.gunnar-int.com

HELD Technologie GmbH (Trossingen, Germany), a new exhibitor, showed its range of double-belt isobaric presses for continuous compression molding and laminating. Known for producing the first double-belt presses to provide a surface pressure of 100 bar (1,470 psi), temperatures up to 400°C/750°F and speeds of 48 m/min (160 ft/min), the company invited potential customers to see technology and run small batches for testing and trials, prior to purchase, at its facility.

Ikonics Advanced Materials Solutions (Duluth, Minn.) exhibited its powder-blasting technology for machining and finishing. The process involves Aeromask, a photo-resist masking film. Users expose the film with the customer’s design, remove the unexposed mask and reportedly blast accurate, burr-free holes in flat or curved parts without delamination in a fraction of the time required for traditional drilling.

Interplastic Corp. (St. Paul, Minn.) introduced Integrity, a new high-performance gel coat for use above and below the waterline in new or patch/repair marine applications. Advantages reportedly include ease of spray-up, resistance to post-spray sag and porosity, and suitability for patching and other repairs. Other benefits include UV resistance, good color and gloss retention, water resistance and crack resistance. The gel coat complies with Maximum Achievable Control Technology (MACT) standards for composites.

Italpresse USA Inc. (Punta Gorda, Fla.), a wholly owned subsidiary of Italpresse SpA, not only accepted the ACE honors in the Process Innovation category (noted above) but, together with collaborator Acell USA, demonstrated the Acell Monolithic Composite process. The low-pressure operation forms Acell’s open-cell foam during the pressing process (the foam does not need to be shaped in a prior step). During the process, the foam allows entrapped air and any volatiles to escape. This, in turn, allows resin to migrate into the cells, forming a strong mechanical bond between the core and the principal part reinforcement.

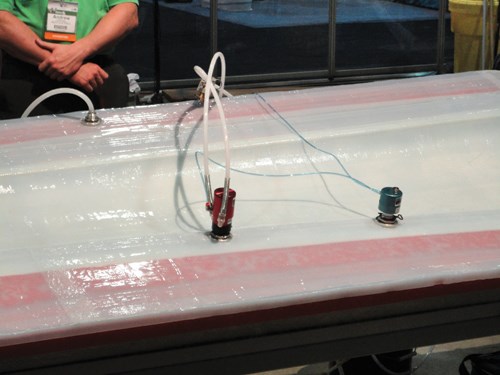

Magnum Venus Plastech (MVP, Clearwater, Fla.) emphasized in its booth and in the show’s Closed Mold Alliance demonstration area (sponsored by Arlington Hts., Ill.-based Composites One) its new Flex Molding system for closed-mold and infusion systems. The system comprises a series of products and technologies designed to increase process efficiency and part repeatability. Features include a highly engineered, reusable silicone vacuum bag, and a network of injection control systems (Patriot Megaject) with injection and vacuum ports on the mold (Turbo Autosprue and Pneumatic Pressure Vacuum Sensor, see photo at right).

Celebrating its 50th anniversary, McClean Anderson (Schofield, Wis.) showcased filament winding equipment. All machines are designed with the company’s Flexwind machine control system, which features the company’s in-house-developed Composite Designer development software. The company touted its support and training services and emphasized its willingness to design a machine solution appropriate to a customer’s application.

Mektech Composites Inc. (Hillsdale, N.J.) offered its passive reactor, a system designed to transform styrene or formaldehyde fumes generated in a manufacturing environment into carbon dioxide and water. Recent system tests reportedly show that inlet formaldehyde levels of 76.5 mg/L are reduced to 0.0135 mg/L at the outlet. Styrene levels of 10.0 ppb at the inlet are reduced to 2.4 ppb at the outlet. The company is working to optimize the system and expects, ultimately, to achieve styrene reduction of 80 to 90 percent (in the 1.0 to 2.0 ppb range).

Micro Air (Wichita, Kan.), another first-time exhibitor, manufacturers a full line of industrial air cleaners, dust collectors, clean-air booths, environmental booths, downdraft tables and commercial air cleaners. The company’s equipment features Roto-Pulse self-cleaning cartridge filters, which are designed to prevent clogging with collected dust particles.

Multiax International (Pordenone, Italy and Grand Rapids, Mich.), a manufacturer of CNC routing equipment, announced at the show that it is now building machines at its Grand Rapids facility. U.S.-based manufacturing is expected to enable better service for the company’s North American customers, and will benefit the company by combining Italian engineering with American manufacturing, says managing director Ed Gauthier. The company will continue its engineering and manufacturing functions in Pordenone, as well.

Oxeon AB (Boras, Sweden) attended the exhibition on the heels of several announcements that its spread-tow fabrics are being used by greater numbers of sporting goods manufacturers, as well as aerospace and marine customers. Following the show, the company announced that it has increased its production capacity due to strong company growth and demand for its TeXtreme Spread Tow fabrics, which reportedly are able to deliver mechanical performance at a reduced weight, while providing an eye-catching surface finish (see also the article listed under "Editor's Picks," at top right).

Plasticolors Inc. (Ashtabula, Ohio) followed up its preshow introduction of a new urethane gel coat for the wind energy market, developed in partnership with PPG Commercial Coatings (Pittsburgh, Pa.). Plasticolors manufactures the gel coat, in clear (ACG200-series) and pigmented (ACG10000-series) forms, while PPG markets and distributes the product. Both forms feature excellent adhesion to epoxy, polyester, vinyl ester or urethane, and an open time of up to three days, says the company.

Polytek Development Corp. (Easton, Pa.), showed its line of liquid mold rubber, casting resins and other specialty molding and casting compounds. The pourable, brushable and sprayable polyurethane rubber, RTV silicone rubber and latex systems are available in a range of hardness and flexibility for countless applications, such as complex molds for architectural components. The brush-on material can be employed to make onsite molds of aging or damaged ornate architectural elements, enabling composites manufacturers to mold accurate reproductions.

Precision Fabrics Group Inc. (Greensboro, N.C.) exhibited its NEXUS synthetic surfacing veils for a wide range of markets, including piping, and other industrial and corrosion-resistant applications. The company revealed that it is developing a new fire-resistant veil for pultruders and filament winders, as well as a new fluoropolymer veil for outstanding corrosion resistance in chemical industry pipes and tanks.

Precision Quincy (Woodstock, Ill.) offered PQ2A Commander, a proprietary SCADA software system that provides control and monitoring capabilities for up to 10 Precision Quincy ovens, all networked to one workstation. It gives the operator access to and control of real-time process variables, batch entry data, recipe setup, trend chart view and history chart view.

Seco Tools (Troy, Mich.), at the show for the first time, demonstrated its range of carbide cutting tools for composites. Targeted to carbon fiber composites, the company’s Dura diamond-coated products, produced via a chemical vapor deposition (CVD) process, offer a performance advantage, says the company, for aerospace applications.

Gel coat manufacturer Sogel (Longueuil, Quebec, Canada) announced that its Hybrathan product, formulated for polyurethane composites, has passed all manufacturing requirements for sanitary applications. The company revealed that it has worked with TSE Industries (Clearwater, Fla.) to develop a polyurethane composite for sanitary applications, using a Hybrathan gel coat with a reinforced polyurethane provided by TSE. This new composite can be molded in composite tooling and reportedly has surpassed all of the American National Standards requirements for plastic bathtubs, shower receptors and shower stalls.

Specialty Products Co. (Corona, Calif.) highlighted its newest trademarked products, water-based BuffAway 1000 fast-cut compound and BuffAway 2000 high-gloss polish. The former removes 600-grit scratches, heavy orange peel and surface oxidation from polyester tooling and production gel coats. The latter removes minor scratches and swirl marks and leaves a mirror finish on production tools. Both are designed for use with a 2,400-rpm rotary buffer.

spheretex America (Ponte Vedra Beach, Fla.) exhibited its range of fiber materials that incorporate hollow microspheres, including its newest product, Sphere Strand. Fiberglass strands are passed through a slurry that contains lightweight thermoplastic microspheres, then heated; the microspheres expand, causing the glass strand to likewise increase its diameter. Suitable for filament winding and pultrusion, the strand also can be incorporated into complex mats for open or closed molding, and is targeted to the marine, transportation and wind markets.

Syrgis Performance Initiators Inc. (Cincinnati, Ohio) presented on the show floor its first Syrging Ahead award to customer A-1 Fiberglass (Hastings, Neb.). A-1 Fiberglass was recognized for reducing the level of variation that is typical in an ambient-cure fiberglass manufacturing facility and improving product quality while reducing overall production cost. Syrgis also revealed that it has received a license to sell its products in China, in the form of a business called Shanghai Syrgis Trading Co. Ltd.

Taconic (Petersburgh, N.Y.), another first-time exhibitor, showed its line of PTFE and PTFE-coated-fiberglass tapes, up to 40-inches/1m wide, for use as a mold release. The reusable and durable tape materials reportedly save labor during large-mold preparation and are currently being used in the wind energy and marine sectors. The company also manufactures a diverse range of additional products, including prepregs for printed circuit boards.

Thermwood Corp. (Dale, Ind.), also a first-timer, showed its range of 3- and 5-axis CNC machining centers for trimming, deflashing or drilling of advanced composite materials. Applications can include machining production patterns or plugs to postcure production operations. The company develops its own control-system software programs, and offers a volumetric compensation system also developed in-house.

In the Bayer booth, a wind blade root ring (top photo) molded with Bayer’s polyurethane as part of a U.S. Department of Energy grant program, featured 63 layers of Vectorply (Phenix City, Ala.) biaxial glass fabric infused with Baydur polyurethane. The ring is said to offer three times the fracture toughness of epoxy in the same application, along with 10 times the fatigue tensile strength and better fatigue crack-resistance. In static testing, the polyurethane matched epoxy performance, but bettered it in dynamic testing.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreRead Next

Spread-tow fabrics reduce waveboard weight

Fanatic (Molln, Austria) recently introduced a new version of its windsurfing waveboard, called FreeWave TeXtreme, made with TeXtreme spread carbon tow fabric from Oxeon AB (Boras, Sweden).

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More