Composites perform water rescue in high-speed rail tunnel

Channeling out the great quantities of water that flow into Spain’s Pajares railway tunnels in the Cantabria Mountain range required an award-winning composites innovation.

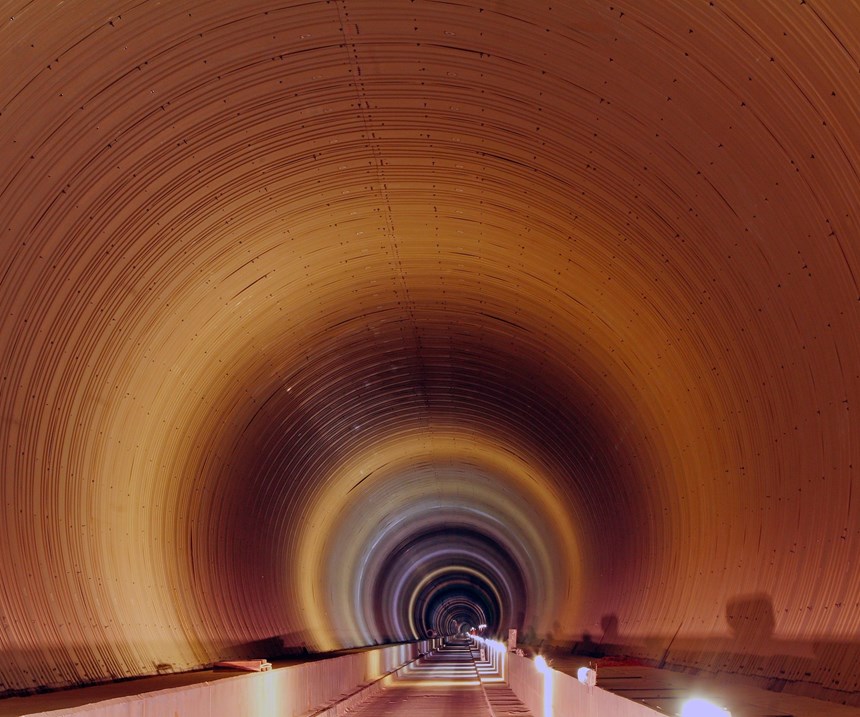

When it comes to water intrusion into transit tunnels, there’s seepage, and then there are the Pajares Tunnels in Spain. Part of a future high-speed rail line intended to link centrally located Madrid to the Principality of Asturias, a region on the country’s northern shoreline known for its rugged coast and mountains, the 24.6-km twin tunnels will enable high-speed rail service through the Cantabria Mountains. Until now, the only rail passage through the mountain range was a winding, sometimes steep route, used primarily for freight, that limited train speeds to 70 km/hr. The new route will provide passenger travel at speeds topping 300 km/hr. The twin tunnels are among the longest in the world, but they have proven to be among the most challenging to engineer. One reason? The Cantabrian region is known for its lush vegetation, enabled by a very wet climate. Positioned on the Bay of Biscay, with wet Atlantic winds trapped by its mountain range, it reportedly can tally up to 1,200 mm of annual precipitation!

Initial tunnel construction was completed in 2009, but unprecedented water infiltration threatened to thwart rail line installation. Water was seeping in from the surrounding soils at a rate a full order of magnitude greater than is seen in most tunnels — up to 2,200 liters/sec, enough to fill an Olympic-sized swimming pool every 20 minutes. The culprits were cracks in the tunnels’ concrete walls. Conventional approaches to waterproofing — injecting polymeric paste into the cracks, installing a polymeric membrane — and other attempts to seal tunnel walls or retrofit tunnels with an existing abatement solution proved ineffective.

A new solution was needed, and Madrid, Spain-based ACCIONA Infraestructuras S.A. – Technology & Innovation Div. was tapped for the job. “We realized we could not stop the water from coming out, so we looked for a way to channel the water,” recalls ACCIONA’s then composites manufacturing head Anurag Bansal, who now serves as the division’s global business development manager. ACCIONA’s innovative solution, consisting of a now-patented composite lining and anchorage system, merited a 2017 JEC Innovation Award in the construction category.

Design challenges

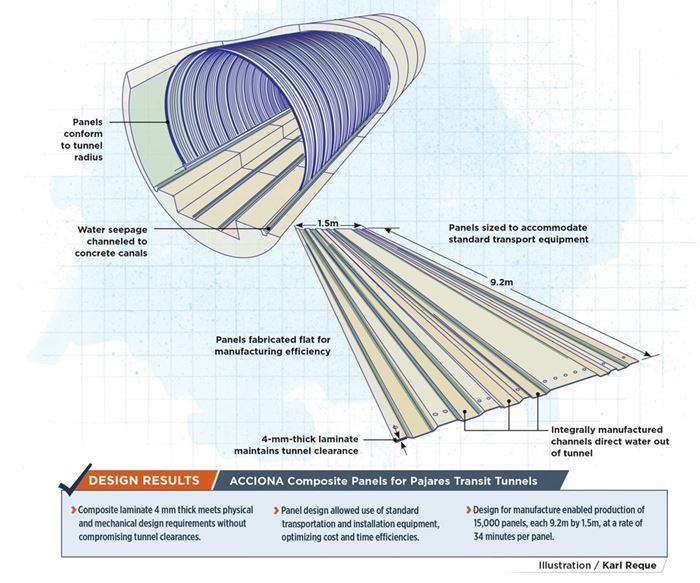

One key consideration that led to the choice of composites over other material options was the need to maintain sufficient tunnel diameter. The raw tunnel cut could have been larger, potentially allowing for a noncomposite water-channeling system, but Bansal emphasizes, “Every additional millimeter that has to be excavated is expensive.” Of course, additional excavation at this point in the project was infeasible, because construction of the tunnel walls was already substantially complete. The water channeling system’s thickness, therefore, could not compromise tunnel clearances. That ruled out conventional options. To meet structural requirements, cement panels, for example, would have had to be 10 cm thick, unacceptably diminishing the tunnel’s size. But the thickness of the laminate in the composite design is a mere 4 mm; and the panel profile, which creates water pathways in the form of integrally manufactured longitudinal ribs/channels, decreases tunnel diameter by an acceptable amount.

Another key consideration was that the water-channeling system’s panels would have to provide adequate radial strength once they were fastened in place against the curved tunnel walls. High-speed trains create significant air pressure as they enter a tunnel. But even more significantly, “when they exit, they create a vacuum that, along with other forces, will try to pull the panels out of their fixtures,” Bansal explains. A specially designed nut-and-bolt anchorage system developed by CELO-APOLO Construction Systems (Castellar del Vallès, Spain) helps keep the panels in place, while the panels themselves are designed to handle the kinds of loads created both by the speeding trains and by the ongoing water seepage.

Bansal’s team also had to find a way to address the seemingly conflicting needs of panel manufacture versus panel installation. On the one hand, flat panels are much easier, faster and more cost-efficient to manufacture than curved panels. On the other hand, the panels need to conform and be secured effectively to the curved tunnel structure. Addressing both sets of needs, the answer was to manufacture flat panels with a considerable proportion of the reinforcement in the longitudinal direction, so that they could be flexed into their final shape as they were installed. Because of the panels’ flexibility, their final shape met design requirements and did not compromise laminate integrity, Bansal reports. The flexibility also enabled relatively easy adaptation to irregular tunnel features.

To create the mix of physical and mechanical properties needed in the panels, the ACCIONA team incorporated three types of glass fiber reinforcement: unidirectional and bidirectional continuous rovings as well as continuous filament mat. The unidirectional product was developed, manufactured and supplied by Owens Corning (Toledo, OH, US). ACCIONA also collaborated with resin manufacturer Scott Bader Co. Ltd. (Northamptonshire, UK) to formulate a workable resin system. This was especially difficult because the resin formulation had to meet stringent subterranean flammability standards, yet also maintain the pre-cure fluid characteristics necessary for manufacturability.

Mass production

With more than two decades of experience in the fabrication of composite components, Bansal nevertheless faced new manufacturing challenges with this project— starting with its sheer magnitude and very tight production schedule. To line more than 200,000m2 of tunnel wall — a stretch of about 10 km — ACCIONA produced more than 15,000 panels, each 9.2m by 1.5m. “We chose pultrusion from the beginning because we needed an automated process,” Bansal explains. Its relatively low labor requirements and high manufacturing consistency also made pultrusion the fabrication method of choice. ACCIONA employed a pultrusion machine built by LYT Composite Equipment Manufacturer (Nanjing, China).

But working with the specially designed resin system added a layer of complexity to the engineering of the pultrusion process. ACCIONA started with Scott Bader Crestapol 1212 pultrusion resin, a rapid-cure methacrylate-based thermosetting resin. Additives needed to meet performance requirements — in particular, a high filler level of 170 phr (per hundred resin) alumina trihydrate (ATH) to meet the flammability standard — changed the resin system’s composition significantly enough to demand a change in processing. A standard pultrusion bath was unworkable because some components of the ACCIONA mixture would settle to the bath’s bottom. Resin injection also was problematic because of the filled resin’s very high viscosity.

Bansal’s team worked with several industry partners on modifications to the resin system, the resin injection system and the injection points that ensured good delivery and wetout of all the glass filaments with the filled Crestapol 1212 resin. Additives provided by BYK-Chemie GmbH (Wesel, Germany) helped ensure uniform wetting and dispersion of inorganic fillers in the resin mixture.

LUM Industry (Boisseuil, France) developed and manufactured the pultrusion mold. Final cycle time for the carefully engineered pultrusion process was 34 minutes per panel.

Additional benefits

The composite lining system covers the 18m arc of the tunnels with a pair of panels. The 9.2m panels overlap by 20 cm at the tunnel apex, which is sufficient to keep water from leaking through the seam — a “path of least resistance” away from the seams is generated by gravity and the water channels that the panels create. Likewise, water won’t leak through the long edge seams. Bansal explains, “The lateral overlap along the edges creates a kind of interlocking, and the mechanical forces [from flexing and anchoring the panels] prevent the panels from moving during installation and usage, thereby keeping the interlocking intact.” When water travels down through the channels, it empties into concrete canals on either side of the tunnel floor and travels out of the tunnel.

Standard transportation equipment can accommodate products up to 10m in length and 1.5m wide, so the paired approach allowed ACCIONA to employ a cost-effective means of transportation to the site. The standard trucking option is also limited to a mass distribution of approximately 8 kg/m2, a limit with which the lightweight composite panels easily complied. Further, the composite panels could be installed using standard installation machinery already on site. Each of these factors helped speed installation. Importantly, the panels also are positioned in such a way that the tunnel structure’s ring segments can still be inspected as required.

Other characteristics of composite materials enhanced the project’s cost efficiency and diminished its environmental impact compared to other material systems, Bansal says. “Steel panels would have had to be galvanized,” he notes. “Otherwise, corrosion and rust would contaminate the water. A steel structure would also require electrical grounding.” In contrast, the composite panels offer easy maintenance and high corrosion-resistance. Production and installation of the composite panels generated significantly lower CO2 emissions than might otherwise have been produced with alternative approaches.

Because of the efficiency with which ACCIONA worked to waterproof the twin tunnels, one of the pair was opened to broad-gauge trains in 2016. The other tunnel opened later that same year. It is hoped that completion of the high-speed rails and the inaugural high-speed ride to Asturias will take place sometime soon after 2020.

Multiple advancements

Asked about the innovations generated by this project, Bansal mentioned the application (first-of-its-kind tunnel lining system), the panel and material design, and the process modifications needed to pultrude the panels in a timely manner. He believes, though, that the most innovative aspect of this project was “designing a solution to a real-world problem. We had to prepare the team to make the panels and, in a very limited time, start up production and continue for two years to make consistent, quality panels.” His pride in the result is apparent — and well deserved.

About the Author

CW contributing writer Karen Mason has been researching and writing about the composites industry for more than 25 years.

Related Content

Gatorbar, NEG, ExxonMobil join forces for composite rebar

ExxonMobil’s Materia Proxima polyolefin thermoset resin systems and glass fiber from NEG-US is used to produce GatorBar, an industry-leading, glass fiber-reinforced composite rebar (GFRP).

Read MoreComposites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

Read MoreNew standard specification supports non-metallic FRP rebar

ASTM International standard D8505 enables further integration of FRP rebar into infrastructure applications.

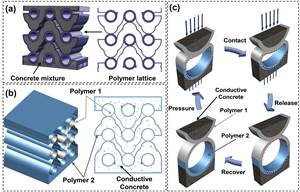

Read More21st century concrete: composite metamaterial with super compressability, energy harvesting

Material comprising 3D-printed, auxetic, reinforced polymer lattices in conductive cement matrix can compress up to 15% and generate electricity for lightweight, mechanically tunable structures with energy harvesting and sensing.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More