Composites Pick Up New Applications in Light Trucks

Long a bastion of steel, the tougher-duty pickup segment of the light truck market is warming to the benefits of composites.

It's a tough time for light-truck manufacturers in North America. For more than a decade, a strong U.S. economy and moderate gasoline and diesel prices fueled a boom in the "light-truck" category, which includes not only pickup trucks but also SUVs and minivans. In fact, for the better part of the last decade, light truck sales — for the first time in automotive history — surpassed those of passenger cars. Consumer sentiment favored the bigger and more luxurious pickups, SUVs and minivans, so U.S. automakers tooled up to deliver what customers wanted. Today, gas prices are closing in on $5/gal in many parts of the U.S., and oil-industry analysts predict global petroleum production will be far lower and more costly than ever before. A significant segment of the North American driving population is downshifting to more fuel-efficient personal transportation. Unfortunately, big automakers, like big ships, cannot change direction rapidly. Lower sales on once-profitable pickups, SUVs and minivans, higher material and component costs, and insufficient supply of the vehicles consumers now want have left North American automakers with a glut of light trucks sitting on lots and showroom floors. Big Three sales in June were down 18 percent compared to last year — their worst month in 15 years, which led to a spate of plant closings and production shifts away from light-truck (and light-truck component) production.

However, the traditional market for full-size pickups — farmers, ranchers, landscapers/green-industry workers, and the construction industry — still exists, and this demographic group is still buying. But, like other drivers, they struggle with high fuel costs — exacerbated by the low MPG ratings this heavier class of vehicle typically achieves — and they are asking what OEMs can do for them. Clearly, the composites industry can provide solutions if their proponents can communicate their benefits clearly and if automakers will listen.

Pickups have been a difficult market for plastics and composites to penetrate, and it seems that much of the problem is perceptual. Traditional pickup owners and OEM design engineers have been reluctant to embrace polymeric materials in this segment, believing they lack the strength and durability for rough-duty use. Well-funded marketing campaigns from the steel industry have made steel synonymous with "toughness" and "durability," features highly valued in a segment where normal use might be termed "abusive" in most passenger cars. Automakers often misperceive that composites are more costly than steel and their production processes are too slow to meet high-volume vehicle builds. (Indeed, higher costs for petroleum feedstocks and transportation have hit the plastics industry, forcing most resin suppliers to raise prices.)

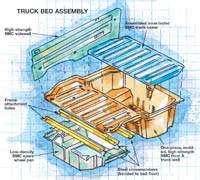

That said, the price of steel has doubled since last fall, adding more than $500 to the cost of the average car since January, and steel suppliers say it is set to increase again. This fact, coupled with recent composites success stories, such as Honda's Ridgeline composite pickup box with in-bed trunk (see "Learn More," at right), has many engineers in the pickup segment taking a second look at composites and plastics. One result is the following sampling of recent, innovative OEM applications that underscore the potential for composites to save weight, increase fuel economy, improve aesthetics, and even improve vehicle styling, safety and functionality.

Stepping Up To Greater Functionality and Safety

Among the most interesting of these new applications are integral steps that unfold or pop out to facilitate ingress into the truck box. The first OEM-integrated tailgate step made its debut on the '08MY Ford Super Duty and has now expanded to the higher volume '09MY F-150 pickups. The hybrid steel/composite application was jointly designed by Ford Motor Co. (Dearborn, Mich.) and Multimatic Inc. (Markham, Ontario, Canada) and produced by Multimatic. A permanent part of the vehicle, the tailgate step is accessed by dropping the tailgate, pulling a "cap" (actually the step) straight out from the end of the gate, lowering the step (which is held in correct position by gravity and geometry), and pulling up an integrated handle for added safety. When they are no longer needed, the step and handle conveniently re-stow inside the tailgate where they are nearly invisible.

While most of the mechanical components are steel, several important and highly visible parts of the multipiece assembly are composites. The step-cap itself, which is the system's largest component and functions as the unit's release lever, is injection molded from 30 percent glass-reinforced polypropylene, supplied by A. Schulman Inc. (Akron, Ohio). The parts were designed with an undercut and ribs for enhanced finger-grip control when pulling steps out from tailgates. A smaller, inner step of the same material features integral clips, pivots and T-stops molded entirely of reinforced plastic without steel reinforcement. Multiple unreinforced acetal (DuPont, Wilmington, Del.) moldings are insert-molded over steel straps for the roller assembly and slide-guide subassemblies.

With a take-rate of 30 percent, the tailgate step was successful enough that Ford commissioned Multimatic to develop another unique application — a box side step, which makes it easier for users to access the front of pickup boxes. This option premiered on Ford's '09MY F-150 pickups with 6.5-ft and 8-ft Styleside boxes. On both driver and passenger sides of the box, an 11-inch/279-mm step extends out from beneath the box with the push of a button then re-stows with a push (a click indicates the latch has engaged) where it is securely mounted to the frame. Each step is designed to support up to 500 lb/227 kg. (The F-150 can be ordered with the box side step alone or in combination with the tailgate step.)

The box side step is also a multipiece hybrid metal/plastic assembly. The most significant plastic content is found in the step-cover assembly and side covers, both molded from thermoplastic polyolefin (mineral-reinforced TPO from LyondellBasell Advanced Polyolefins, Rotterdam, The Netherlands), and the actuating button, a glass fiber/mineral-reinforced nylon 6 supplied by BASF Corp. (Wyandotte, Mich.). Both applications are major new pickup innovations and are covered under multiple patents.

A Better Hard Tonneau Cover

Another interesting application is actually a new twist on a traditional pickup option: the hard tonneau cover. Usually made of fiberglass sheet molding compound (SMC), hard tonneau covers provide two important benefits to consumers. First, they can increase fuel economy by reducing air turbulence in the bed — an improvement in drag coefficient of as much as 6.5 percent, according to a Specialty Equipment Market Assn. (SEMA, Diamond Bar, Calif.) study. Second, they provide lockable storage for valuables kept in the bed. Hard tonneau covers also provide additional revenue for truck dealers and aftermarket component suppliers.

However, traditional tonneau covers have challenges. Fiberglass units often are heavy enough to cancel out aerodynamic improvements and make it difficult for one person to install and remove. They also tend to be expensive and, because of conventional paint finishes, are easily scratched or chipped during transit or service life, leading to maintenance issues. Early thermoplastic alternatives lacked SMC's stiffness, so underside bracing was required, which intruded into and reduced cargo space and limited customization options. These units also had problems with fit/finish, durability and cosmetics. Now there's another option.

Penda Corp. (Portage, Wis.) is supplying General Motors Corp. (Detroit, Mich.) with the first original-equipment, thermoformed, color-matched hard tonneau covers for light trucks. These in-mold colored (IMC), high-gloss, thermoplastic composite systems fit full-size GMC and Chevrolet pickups and are designed to overcome issues with traditional fiberglass and earlier-generation thermoplastic tonneau covers for both dealers and consumers. Penda, a long-time leader in thermoplastic bed liners and itself a producer of fiberglass tonneau covers, studied the bed-accessories market for two years. The study showed that the segment had not kept pace with changes in the versatility/functionality being designed into pickups by OEMs and in the comfort, styling and features demanded by consumers.

Penda claims its new thermoplastic cover delivers all of the benefits (strength and appearance) of fiberglass units while eliminating all the drawbacks (weight, durability, functional complexity and repair issues). According to Penda, it provides the strength of fiberglass without the need for underside bracing. The new design weighs 25 to 37 percent less than comparably sized fiberglass units, thus eliminating traditional trade-offs between reduced drag and increased weight, so fuel economy is improved. The weight reduction reportedly also means most truck owners can lift, remove and store the unit without help in a matter of seconds, thanks to a patented quick-release V-hinge system, which instantly locks and unlocks the cover attachment with an audible "click," indicating attachment/detachment. Unlike earlier systems with greater complexity, dealers can install these covers on a vehicle in 20 to 30 minutes. The system also provides increased lid-opening height (a function of the hinge system and longer struts).

Use of IMC technology reduces maintenance issues: a truck owner can buff out scratches and minor damage rather than repaint, and the materials chosen provide superior resistance to UV fading and degradation (they are color stable to 5000 kJ of xenon arc exposure per SAE J1960). Broad thermal resistance (85°C to -30°C/185°F to -22°F) helps the cover resist cracking, an issue with earlier systems. Additionally, exterior styling cues complement and enhance vehicle appearance, and it's no mean feat to get in-mold colored polymer to color-match painted vehicle bodies in terms of gloss, color and depth of image (DOI), particularly with metallic finishes. The company reports readings in the high 80s for gloss and low- to mid-80s for DOI, which is significantly higher than that seen with vehicle paint, accounting for the mirror-like finish.

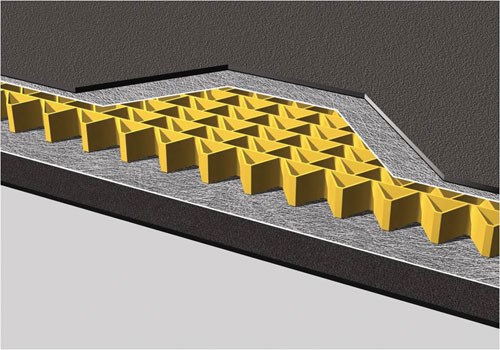

The tonneau cover's patented construction features a multilayer structural bottom layer and a multilayer capstock for aesthetics. The structural layer, which provides excellent stiffness and strength at low weight as well as a flat bonding surface, is a sandwich structure consisting of skins of polyethylene terephthalate (PET) resin (Composites One/Cook Composites, Arlington Heights, Ill.) reinforced with a combination of chopped-strand and continuous-fiber glass mat (also Composites One) surrounding a core of phenolic-resin/kraft-paper honeycomb (Tricel Honeycomb Corp., Gurnee, Ill.). Penda produces the sandwich structure on site. The decorative capstock, supplied by SENOPLAST Klepsch & Co. GmbH (Piesendorf, Austria) is a three-layer thermoformed sheet consisting of an acrylonitrile butadiene styrene (ABS) bottom layer, a middle layer of pigmented acrylic, and a top layer of clear acrylic. The capstock prevents read-through of structure lines from the bottom layer and provides the smooth, high-gloss, color-matched Class A appearance. The underside of the bottom layer has a black, grained finish. Steel-reinforced mounting points/plates bonded into the structural layer facilitate attachment of the capstock, creating an integral bond that is virtually unbreakable, leaves no witness marks and eliminates the cracking/delamination issues seen with previous systems. A Devcon adhesive (ITW Devcon, Danvers, Mass.) is used to seal edges of the unit strictly for aesthetic purposes.

No More Chipping or Rust

Another in-mold color application has solved longstanding problems of paint chipping in wheel-lip moldings, or wheel flares, that provide an "aggressive" color contrast to and protect the edges of wheel wells in steel body panels. A new grade of TPO alloy developed by Solvay Engineered Polymers, now part of LyondellBasell (Auburn Hills, Mich.) is compounded with pigment, producing a glossy, metallic look that color matches accent-color wheel-flare body paint on two-tone '08MY Ford F-250 Super Duty pickups. The parts replace previous painted TPO parts that were subject to chipping as water and debris were kicked up by tires.

Injection molded by the Plastcoat Div. of Decoma International (Mississauga, Ontario, Canada), the parts' integral high-gloss, metallic color — initially offered in Pueblo Gold, Dark Shadow Gray, or Brilliant Silver — is suspended in an alloy of polypropylene and specialty rubber (Indure X-76 resin), which has been custom formulated to provide a good balance of stiffness, impact-, scratch- and mar-resistance, weatherability and aesthetics, plus high flow for enhanced processability.

By replacing painted TPO with IMC TPO parts, Ford eliminated the time, energy, scrap and volatile organic compound (VOC) emissions associated with paint, creating a more consistent, environmentally friendly product. Parts are easily recycled during production and at end of vehicle life — much more so than painted parts would be.

However, the real significance of this application is that it overcame the longstanding challenge of creating a high-gloss, metallic IMC part with no visible flow lines that could color match vehicle body paint at all viewing angles. Among the issues that had to be solved was that pigment for IMC applications must provide thermal stability two times greater than that typically seen in paint (177°C to 232°C/350°F to 450°F vs. 82°C to 121°C/180°F to 250°F). Also, paint typically uses pigment-loading levels of 20 to 45 percent and is applied in very-thin films (~60 to 80 microns). In contrast, typical IMC parts have pigment loadings of less than 2 percent and are 2-mm to 3-mm (0.08-inch to 0.12-inch) thick, both of which can have a profound impact on light scatter and perceived color/gloss. Tooling surface and gating also were critical to minimize surface flow lines, which are typically pronounced in metallic parts due to the larger size of the pigment. Solvay formulated the grade for a high melt-flow rate (35 MFR) to enhance processability. And Plastcoat worked with toolmaker Accurate Mould Co. Ltd. (Toronto, Ontario, Canada) to design proprietary gating for the tool to minimize turbulence at the flow front, thus reducing "rollover," the tendency of metallic flakes to tumble significantly during injection, a situation that can "freeze" flakes edge-on to the part surface when the flow front solidifies. This results in reflective "gaps" that can lead to inconsistent metallic effects in the part finish.

The parts meet Ford's WSS-M2P181-B Paint Performance QMS Target Values specification for Exterior Flexible Substrates in a range of light to dark colors. Because of the success of the program, color offerings for the IMC system are being expanded on '09MY F-250 pickups. Additionally, the system is being considered for additional exterior applications, including body side moldings, door-trim cladding, and rocker panels.

A Stowable Bed Extender

For those who use a pickup for anything other than commuting, a bed extender can add bed carrying capacity by containing cargo and allowing it to extend out onto an open tailgate. A bed extender typically consists of a hinged "fence" made of bent-steel tubing, with rubber or plastic bumpers/feet at the top and bottom to prevent damage/scuffing to the bed. The unit bolts/clips to the pickup bed sidewalls in close proximity to the tailgate hinges. In "cargo" mode, the fence extends out over and encloses the perimeter of the lowered tailgate, but it can be flipped inward — "grocery" mode — to corral smaller cargo close to the tailgate, preventing the latter from drifting deep into the box. With traditional steel bed extenders, however, there is no way to tuck them out of the way when you don't want them in one of those two positions; they have to be unhitched and removed from the vehicle or pushed to the cab end of the bed where they reduce cargo-carrying capacity. They're also heavy, which affects fuel economy and ease of attachment/detachment from the bed, and they are subject to corrosion.

Now, Ford and ABC Group (Toronto, Ontario, Canada) have found a way to retain the useful features of traditional steel bed extenders while addressing their shortcomings. For Ford's '08MY F-Series Super Duty pickups, ABC Group is providing the first structural composite bed extender, which — in addition to traditional cargo- and grocery-mode positions — can be uncoupled in the middle of the unit (thanks to a unique structural plastic hinge system) and conveniently folded/stowed against bed sidewalls behind the rear wheel wells (see photo series, at right). In a fourth position, uncoupled and extended straight back out along the sides of the tailgate, it provides extra lateral control of cargo that extends beyond the bed.

Blow molded from black 15 percent glass-reinforced polypropylene, the extender components exhibit a Class A textured finish right out of the tool. This high-strength material/process solution met Ford's requirements for impact strength (particularly at low temperatures), scratch-, mar- and weather resistance and aesthetics.

The design features four rail-like panels that attach to each other (via plastic hinges) and pivot to allow the system to be moved from one position to another. Clips hold panels together in stowaway mode, and a lever swings to lock panels in cargo mode. Molded-in ramps and snap-ins reduce the number of additional components required.

The composite bed extender will be expanded as an option on the new '09MY F-150, due out this fall.

Tougher Fenders for Dually Pickups

Dually pickups are the heaviest weight class for light trucks and sport a double (dual) set of wheels on the rear axle for extra weight-carrying capacity. As such, they are often used for towing horse trailers, boats, fifth-wheel RVs and other heavier gear. Because rear fenders on dually trucks flare out to accommodate the extra set of wheels and are wider than the rest of the vehicle body, they are especially susceptible to scratches, scrapes and other damage, especially during towing maneuvers.

The deep draw on these components and the fact they're damage-prone prompted automakers to replace steel with reinforced reaction injection molded (RRIM'd) composites in dually fenders. However, RRIM'd parts have posed challenges of their own. First, because the RRIM'd parts have a higher CLTE (coefficient of linear thermal expansion) than the adjacent steel body panels, there can be fit/finish issues due to differentials in thermal-expansion co-efficients between the two materials. Additionally, RRIM'd parts can fracture during low-temperature impacts.

To eliminate these issues, Chrysler LLC (Auburn Hills, Mich.) made a running midcycle changeover on its Dodge Ram dually pickups about three years ago, going to a compression-moldable, twin-layer/dual-formula SMC system instead. Supplied by Meridian Automotive Systems (Allen Park, Mich.), the outer-fender panel uses a newer toughened, microcrack-resistant SMC grade (resin supplied by AOC LLC, Collierville, Tenn.) and in-mold color to achieve a Class A finish, putting a more durable material in the location most prone to damage. To keep mass down (because SMC has a higher density than RIM), an inner-reinforcement layer uses a newer low-density (sg = 1.3) SMC grade from Ashland Performance Materials, Composite Polymers (Dublin, Ohio). The completed SMC fender is 20 percent lighter than comparable steel systems. Inner and outer layers are bonded using Pliogrip 9100 urethane adhesive, from Ashland Performance Materials, Specialty Polymers & Adhesives (Dublin) to form the complete assembly, and the fenders are then topcoated using a low-bake, two-component basecoat and clearcoat system (DuPont Automotive, Troy, Mich.). The result is the flexibility to achieve deeper draws and a smoother, more stable Class A surface. SMC retains the corrosion resistance of RIM at a comparable cost and provides better impact resistance at extreme temperatures than either RIM or steel.

Future Composites Applications in Pickups

In a recent broadcast radio conversation with WWJ-AM automotive journalist Jeff Gilbert, John Wolkonowicz, senior automotive analyst with Global Insight (Waltham, Mass.), pointedly commented about the rapid change in consumer sentiment away from light trucks and toward small cars. "I have never seen such a change in consumer taste and seen a change happen as fast as we've seen in the last couple of months."

According to Tyler Hardy, director Engineering - Composite Products at Meridian Automotive Systems, "Fuel economy is clearly becoming a driving factor for new-vehicle developments across the board, and composites will play a key role in mass reduction. We're already seeing OEMs offering vehicles in production volumes of less than 100,000 units annually. At those volumes, the lower tooling investment typical of composites really starts to make them look economical to OEMs." Composites, he adds, also are attractive for midcycle enhancements and specialty vehicles.

"Light-truck customers are expecting more from their vehicles these days, and composites add value, improve durability, styling, and fuel economy, reduce production costs and produce designs that would be impossibly expensive or impossible in steel," Hardy maintains. "We're seeing more and more demand for features like in-bed trunks, pass-through midgates, removable roofs, underbody shields and body side stowage." There also is the potential, he notes, for hard tonneau covers, currently an option on most pickups, to become standard equipment as a fuel-economy measure, in the same way that underbody shields have been in Europe for a decade. "We're optimistic about the future of composites in the automotive industry."

Related Content

Aptera joins forces with C.P.C. Group to accelerate solar EV production

Specialized composite bodies are being produced in Modena, Italy, for Aptera’s BinC vehicle, enabling eventual manufacturing ramp-up of 40 vehicles/day to meet demand targets.

Read MoreAOC introduces UV-Resistant Automotive System for SMC parts

AOC’s novel formulation, tested in the lab and in real-world environments, delivers a deep black, molded-in color that resists fading and offers high scratch resistance.

Read MoreMar-Bal expands SMC expertise through AltraSet materials division

The BMC company aims to fill the SMC market gap for those seeking optimal, low-volume demand with custom formulation and high material value.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreRead Next

Inside-the-box thinking pays off for Honda

New Ridgeline pickup features innovative composite box with first-ever molded-in trunk.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)