Peak 10’s 60,166-square-foot purpose-built, multistory data center facility in North Tampa, Fla., U.S., was fabricated using Metromont’s C-GRID-reinforced insulated precast concrete panels for high efficiency operation. Photo Credit: Metromont

Internet connectivity drives today’s world, affecting life at all scales. All online activity generates data, and even though the data itself is transmitted and received wirelessly, physical hardware is what makes it possible.

Some of this hardware fits in your pocket, laptop bag or under a desk in the office, but much more extensive data sets are stored in data centers. A data center is a specialized facility designed to accommodate computer systems and related components, such as storage modules, networking equipment and servers, to sort, process and distribute large amounts of digital information.

The data center market is expanding dramatically with the increase in data production, driven by the growing demand for digital services, the rapid progression of cloud computing and the implementation of the Internet of Things (IoT). The rising adoption of edge computing, which involves bringing computing resources closer to end-users to reduce latency and improve performance, is also fueling this expansion.

Because of this, the data center industry is under increasing pressure from building regulators, such as The American Society of Heating, Refrigerating and Air Conditioning Engineers (ASHRAE) in the U.S. with its recently updated ASHRAE Standard 90.4 Energy Standard for Data Centers, to improve its sustainability.

ASHRAE 90.4 is a performance-based design standard where the energy efficiency of the mechanical and electrical systems is built around a power usage effectiveness (PUE) metric. It establishes the minimum energy-efficiency requirements for the design and operation of data centers, particularly considering their unique load case compared to other buildings to address their environmental impact.

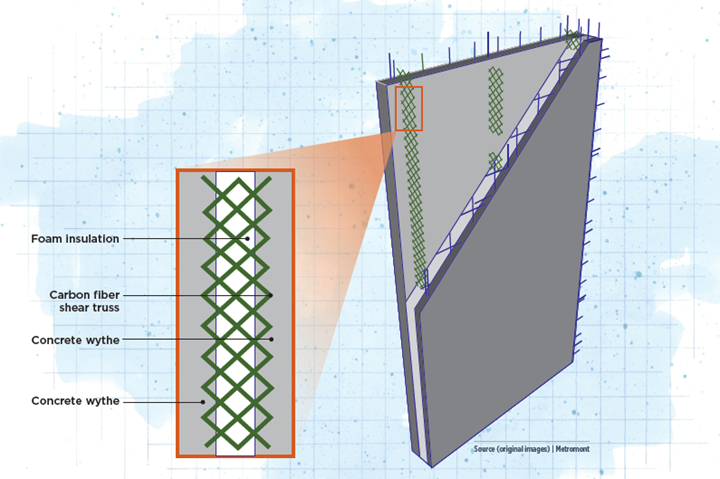

A significant factor in the energy efficiency of a data center is the wall system’s thermal performance — the better the data center insulation, the less energy it consumes. Greenville, S.C., U.S.-based precast concrete firm Metromont has worked in partnership with other North American precasters as part of the AltusGroup to develop a proprietary carbon fiber lattice structure-reinforced insulated precast concrete wall panel marketed under the CarbonCast brand name to help address environmentally friendly constructions.

Illustrated by Susan Kraus.

Design challenges

“Precast concrete panel systems are ideal for providing the hardened, windowless exterior walls preferred by owners and operators of mission-critical data center facilities,” Metromont’s senior vice president of engineering Harry Gleich explains. “Our precast wall systems not only provide maximum security for the contents of the building but are also engineered to satisfy major ASHRAE regulatory energy-efficiency requirements.”

“Data centers need to be operated within a safe temperature zone to remain functional,” Gleich continues. “An overheated server can cause downtime that may lead to thousands of dollars in financial loss, so many data center operators opt to overcool their data centers. However, should data centers be one degree closer to the specified temperature safe zone, they would save around 4% on energy costs. Producing a building with high thermal performance is a major driver for implementing our insulated precast concrete panels in this application.”

The challenges of data center construction extend beyond thermal management; these buildings are typically designed with long clear spans inside to maximize the usable area. Further, they must be fire- and storm-resistant and as equipment inside a data center is heavy, the wall panels used to support each story must be very strong. These criteria drove the need for C-GRID, a carbon fiber and epoxy resin mesh used to reinforce the prefabricated panels to reduce their weight, cut construction costs and prolong service life.

Panel design and construction

Metromont’s C-GRID-reinforced insulated precast concrete panels used for data centers typically measure 12 square feet (depending on the data center design) and 9 inches (229 millimeters) thick, made up of two 3-inch (76.2-millimeter) thick concrete layers, called wythes, that flank 3 inches of extruded polystyrene (XPS) insulation material. The concrete sections provide strength for the panel, while the insulation layer offers its thermal characteristics. The C-GRID bridges the three layers, strengthening the panel and making the layers behave like a single construction.

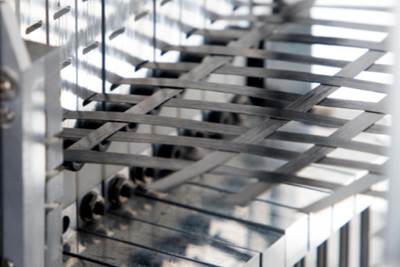

Composite materials and technical textiles firm Chomarat (Williamston, S.C., U.S.) manufactures C-GRID. “C-GRID is formed in a continuous rotary laid-scrim process in which cross-direction carbon tows are aligned in a 0°/90° orientation and then impregnated with a proprietary thermoset epoxy resin system,” explains John Leatham, director of sales and marketing at Chomarat. “The tough, heat-cured epoxy resin chemically binds the tows perpendicular to each other in the lattice structure [grid].”

The C-GRID carbon fiber lattice structure reinforcement is perpendicularly positioned 0.75 inch (19 millimeters) deep into the 3-inch inner and outer concrete, bridging the three layers, strengthening the panel and making it behave like a single construction. Photo Credit: Metromont

Chomarat developed a two-component, high glass transition temperature (Tg) epoxy system for C-GRID that helps precasters meet fire rating requirements for precast-insulated wall panels. “We can design C-GRID constructions to meet the specific requirements of the application,” says Leatham. “Adjusting the tow strand sizes from 3K to 60K and spacing from 1 inch to 4 inches controls the tensile strength of the reinforcement per square foot and the chemistries, including latexes, plastisol and thermoplastics, can be adjusted for desired performance.”

The data center precast panels are manufactured in Metromont’s factory under controlled conditions. This production method is faster and more efficient than manufacturing concrete panels on the build site which reduces waste that would be generated in an on-site production process. The concrete sections of the panels are made using cement, sand and aggregate combined with a water-to-cement ratio of 0.38, along with superplasticizers and mixing agents, to improve durability.

“The 0.38 water-to-cement ratio is typical for a data center panel because it’s the least permeable concrete we make,” notes Gleich, “While water intrusion is part of what we want to prevent, this concrete blend also resists salts and acid rains which are more corrosive.”

Accelerated cure, durable panel construction

The panel construction starts with the outer wythe mixture gravity-poured into a mold. Before it cures, the C-GRID reinforcement is perpendicularly positioned 0.75 inch (19 millimeters) deep into the 3-inch outer concrete layer. The amount of C-GRID added to the panel structure depends on the desired panel performance, though typically it’s placed every 24 inches (610 millimeters) throughout the panel width.

“There is a sweet spot from a volumetric perspective that means you don’t gain performance by adding too much of the C-GRID into the panel, and every 2 feet is where we have found it to be for much of our data center panel designs,” explains Gleich. “We design the C-GRID reinforcements to coincide with the width of the insulation sheets, that typically are 2 feet wide, which helps with construction time, as no modification to the insulation width is needed.”

The XPS insulation is positioned next. XPS is manufactured using a continuous process, resulting in a closed-cell structure with a smooth and dimensionally accurate outer surface finish. The XPS construction uses highly efficient blowing agents selected explicitly for low thermal conductivity and diffusivity, helping the insulation retain its properties over time.

“The durability of XPS insulation is perhaps C-GRID’s most important environmental consideration,” remarks Gleich. “The closed-cell structure and lack of voids in XPS impart not only the material’s thermal properties but also its moisture penetration resistance without using a facer or laminate, enabling a much longer service life than some other types of insulating materials.”

An overhead of the Peak 10 data center constructed using Metromont’s C-GRID-reinforced, XPS-insulated precast concrete panels. Note, the site is clear of concrete fabrication systems as the panels are precast off-site and brought in just as they are needed for installation. Photo Credit: Metromont.

Gleich notes that XPS insulation has a slick outer surface when produced, suboptimal for adhering to the concrete wythes. As such, Metromont sandblasts the XPS insulation’s outer surface to develop a high surface area finish, improving the adhesion between the insulation and the concrete, and thus optimizing the panel’s performance.

“Sandblasting the insulation before adhering it to the concrete improves the strength capacity of the panel as a whole system,” explains Gleich. “It unlocks an additional 25 psi compression strength performance from the XPS material, which otherwise would not be there without the sandblasting.”

Metromont doesn’t often use accelerators for the curing of outer panels because once the insulation is placed on top, the concrete’s exothermic reaction is contained by the insulation, which accelerates the curing process. The inner wythe (upper layer in the mold) is then poured. It is chemically identical to the outer wythe, though an accelerator is added to the mix, dehydrating it to help it cure faster.

“Precasting the panel in a controlled environment means we can achieve a panel with a 3,500-psi compressive strength after just 8 hours of curing — this represents as little as 5% of the time it would take a traditional mix to cure,” highlights Gleich. Thanks to the C-GRID and one-third of the panel being low-density (33 kilograms per square meter) XPS, the panels can be as much as 50% lighter than an equivalent solid concrete panel.

“This low weight impacts the cost and logistics of the build,” says Gleich. “The lighter C-GRID-reinforced panels mean they can be transported in smaller, lighter trucks, which are cheaper and easier to get into job sites, or the larger trucks can carry three times as many panels per truckload.

“Because we precast these panels bespoke to order, they are prepared for reaching the job site only when needed,” he continues. “Precasting massively reduces the on-site logistics and can save months set aside for concrete mold fabrication and curing downtime on every panel of a large building.”

Bespoke to the build

Metromont tailors the precast panel specification, including the concrete mix, panel and insulation thicknesses and panel size to deliver the strength, durability, security, energy efficiency and the lifecycle unique to each data center structure requirements.

“Our built-in, edge-to-edge insulation means precast panels can be engineered to achieve any required R-value [thermal resistance],” says Gleich. “The three-part ‘sandwich’ panel system acts as a vapor barrier, ensuring effective control of the interior temperature and humidity levels, which is crucial in data centers since they contain extremely sensitive equipment.”

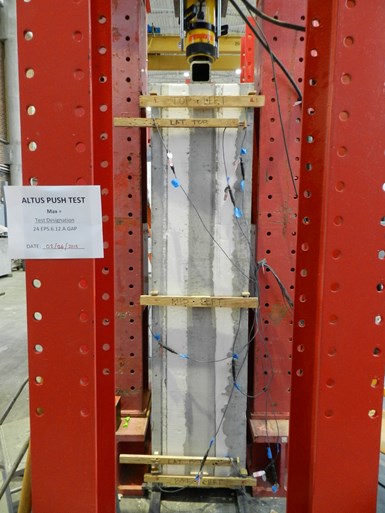

Wall panels with C-GRID have been tested extensively at major university laboratories. This shear test uses three concrete wythes and two cores of rigid foam insulation to minimize the eccentric location of the applied shear. (Two concrete wythes encase one layer of rigid foam for in-field applications.) Load was applied vertically to the top surface of the middle concrete wythe to evaluate the capacity of the shear transfer mechanism. A freeze-thaw aging regimen was also included. Photo Credit: AltusGroup Inc.

Leatham adds, “The C-GRID reinforcement also supports the thermal performance of the panel system. As a nonmetallic connector, C-GRID has the benefit of ultralow thermal conductivity, enabling precast producers to manufacture highly efficient insulated wall panels for data centers, significantly lowering temperature control costs.”

Metromont is working with the Precast/Prestressed Concrete Institute (PCI, Chicago, Ill., U.S.), the technical institute and trade association for the precast, prestressed concrete structures industry, to develop a building code for composite-reinforced precast insulated panels like the ones it uses for data center construction.

“From this, we hope to characterize the data center building challenges and ensure the highest efficiency buildings,” says Gleich. “As the world will not stop demanding data anytime soon, the rate at which the industry will build data centers means their efficiency and environmental influence must continue to be addressed.”

Related Content

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

Automated weaving system targets high-performance, high-volume applications

Startup WEAV3D Inc.’s technology produces highly tunable, woven lattice reinforcements for cost-effective, high-volume automotive composites and precast concrete applications.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More