Composites' role in seawater reverse osmosis desalination

Part two of a two-part series on the role of composites for meeting California’s 21st-century water needs.

In an effort to solve water shortage issues in the U.S. state of California, Governor Gavin Newsom has ordered key state agencies to develop a blueprint for meeting California’s 21st century water needs, to ensure safe and resilient water supplies, flood protection and healthy waterways for the state’s communities, economy and environment. Two solutions in which composites play a significant role are wastewater purification (which was featured in CW's January 2020 feature “Composites help take the waste out of wastewater”) and, the focus of this report, seawater reverse osmosis (SWRO) desalination.

The problem in California is easy to understand, but difficult to solve: The original configuration of rivers, streams, lakes, bays and underground water (aquifers) in California has been reconfigured so extensively over the years to accommodate a growing population and conflicting interests that these resources cannot be relied upon to meet future water needs — even the near future. Conflicting needs have led to increasingly acrimonious water wars in the state. In “The Dreamt Land” (Alfred A. Knopf, New York, 2019), author Mark Arax suggests 10 ideas that “might bring a little sanity to the delirium, and maybe a small truce to the water wars.” One of these ideas is to “… pass statewide measures to fund the building of ocean desalination plants. … ”

The benefits of seawater desalination

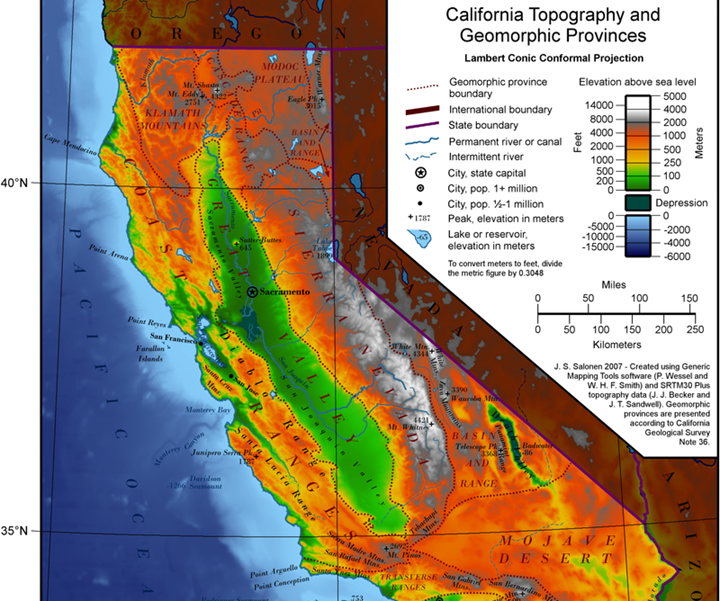

The Californian shoreline measures 3,427 miles (5,515 kilometers), according to the National Oceanic and Atmospheric Administration (NOAA, Dept. of Commerce, Wash., D.C., U.S.). Those miles of seacoast (Fig. 1) offer an extensive opportunity for California to develop additional resources for safe drinking water through the use of seawater reverse osmosis (SWRO) desalination.

SWRO basically consists of pumping seawater from an ocean-based intake system into the SWRO plant. The seawater is first directed into pre-treatment processes to eliminate algae, organic materials and other particles and impurities. It is then pumped at high pressure through an extensive series of RO semi-permeable membranes — for example, spiral-wound polyamide membranes made by DuPont (Dow Filmtec) or by Toray Membrane USA (TMUS, Poway, Calif., U.S.), part of Toray Industries (Tokyo, Japan).

Peter Metcalfe, manager of applications engineering for TMUS, explains: “Polyamide type spiral-wound RO membranes consist of a cross-linked, fully aromatic polyamide separation layer, with a supporting layer of polysulfone and a polyester fabric base, in a spiral-wound RO element.”

The RO membranes separate dissolved salt and other minerals and impurities from the water molecules. The desalinated/purified water is distributed to post-treatment and supply lines, and the concentrated brine separated from the water is discharged back into the ocean.

These membrane modules are installed in pressure vessels designed to withstand the pressure of the incoming surge of seawater that is pumped through them, and multiple membrane modules are typically encased in each pressure vessel. Each grouping of pressure vessels — all fed through a common pressurized header — is called a train, and the trains are arranged in racks.

The best pressure vessels are made from fiberglass-reinforced plastic (FRP) materials manufactured by filament winding in compliance with the Boiler and Pressure Vessel Code of the American Society of Mechanical Engineers (ASME), Section X, Fiber Reinforced Plastic Pressure Vessels. These precisely engineered products meet high pressure requirements and resolve steel’s issues with corrosion, weight and inside surface quality.

In addition to seawater desalination, RO technology is also used for numerous other applications, from California car washes to wastewater recycling facilities. In the case of the latter, RO membranes are usually housed in FRP filament-wound pressure vessels manufactured to meet 300-psi certification, compared to the up to 1,200 psi required for SWRO. The operating pressures in these facilities are much lower than pressures in SWRO because the salt concentration is so much less. Saltwater concentration in wastewater is typically <0.2%, compared to 3.5% in seawater.

SWRO on the California coast

At this time, only two active SWRO operations are operating on California’s coast, plus one on its offshore island, Santa Catalina.

Carlsbad, San Diego County. Poseidon Water — headquartered in Boston, Mass., U.S., with offices in California — was the developer and is now the owner-operator of the Claude “Bud” Lewis Desalination Plant in Carlsbad. Poseidon’s leading specialty is in large-scale SWRO desalination plants. The first large-scale SWRO plant on California’s coastline, the Carlsbad plant was designed and constructed by Kiewit Shea Desalination (Carlsbad) and Israel-based IDE Technologies. In operation since December 2015, it produces 50 million gallons per day of fresh, desalinated drinking water for about 400,000 people in San Diego County.

Fig. 2 About 50 million gallons per day of drinking water produced for 400,000 of San Diego County’s residents by the SWRO plant in Carlsbad depends on 2,236 filament-wound E-glass/epoxy pressure vessels supplied by Protec-Arisawa America. These vessels are rated as needed in specific areas for 1,200, 600 or 450 psi, and house 17,888 membrane modules. Source | Poseidon

It has produced more than 50 billion gallons of drinking water since it entered service in late 2015.

Carlsbad’s RO process operates 2,236 filament-wound E-glass/epoxy pressure vessels made by Protec-Arisawa America (Vista, Calif.) rated as needed in specific areas for 1,200, 600 or 450 psi, and housing 17,888 Dow Filmtec membrane modules (eight per vessel). The Carlsbad plant pumps approximately 100 million gallons per day of Pacific Ocean seawater from the Agua Hedionda Lagoon — a coastal wetlands in Carlsbad — and transports it to the SWRO plant through a 72-inch seawater feed pipe. Of the 100 million gallons per day intake, 50 million gallons is desalinated into drinking water, and 50 million gallons of brine waste is diluted to reduce its salinity and discharged back into the ocean.

Fig. 3 The City of Santa Barbara runs 90 BPV 8-1200 pressure vessels rated at 1,200 psi, made in the European Union by Protec-Arisawa Europe, S.A., housing 720 membrane modules, producing 3 million gallons per day for its 93,000 residents — plus 5 million tourists annually. Source | Donna Dawson/Charles E. Meyer SWRO Desalination plant

City of Santa Barbara, Santa Barbara County. The City of Santa Barbara is the owner-operator of The Charles E. Meyer SWRO desalination plant, also designed and constructed by Kiewit and IDE. First built in 1991, then deactivated a few years later, an upgrade was approved by the Santa Barbara City Council in 2015, and the improved design began production in May 2017.

The city’s water resources manager Joshua Haggmark describes Santa Barbara’s geography between 4,000-foot mountains and the ocean as simulating an island — an island in need of a secure water supply. “Seawater desalination is not about growth in Santa Barbara,” Haggmark states, “it’s about providing important diversity in water supply.” The plant capacity of 3 million gallons per day —produced by three trains each producing one million gallons per day —brings an important addition to existing sources of potable water for the city’s population of more than 93,000 residents (plus 5 million tourists annually). There is space at the facility for five additional trains, which could expand the plant's capacity to more than 8 million gallons per day, if needed.

Santa Barbara’s operation runs 90 model BPV 8-1200 pressure vessels rated for 1,200 psi. Each pressure vessel has an 8-inch outside diameter and is 28.4 feet long. They are made in the European Union by Protec-Arisawa Europe, S.A. Eight Dow Filmtec membrane modules are loaded into each pressure vessel.

The process begins a half-mile offshore, where about 6 million gallons per day of seawater is pumped into the system at 0.5 feet per second through a “tapered intake wedge wire [screen] with 1-millimeter screen openings, which minimizes both impingement and entrainment of marine organisms, while not restricting the flow of seawater,” says Steve Wait, director of sales for IDE Technologies. The seawater flows into the plant through a high-density polyethylene (HDPE) pipe installed inside an old concrete sewer pipe. Wait cautions, “This is not comparable to power plants that once used open intake pipes to pump seawater at some 400 million gallons per day into their system for cooling. The Ocean Plan Amendment stopped this practice. Desal intake structure and brine discharge is much easier on the ocean than that cooling system.”

Fig. 4 At Santa Barbara’s SWRO plant, three trains currently each produce 1 million gallons of water per day. Space has been allowed for installation of five additional trains, expanding capacity to more than 8 million gallons per day, if needed. Source | Donna Dawson/Charles E. Meyer SWRO Desalination plant

As seawater enters the desalination system, coagulants and other chemicals are added, and the mix then proceeds through gravel, anthracite and sand filters. Surprisingly, Wait says, “We had to grow bacteria in this area. The bacteria eat troublesome micronutrients and increase efficiency.” The resulting clear water is pumped through spiral-wound, 10-micron cartridge gravitational sand filters — “like an oil filter in a car” — that remove sand and other elements that might scratch the RO membranes.

Fig. 5 Instruments monitor each train’s process steps of chemical additions, filters, high-pressure RO system and post-treatment — producing clear, clean drinking water. Source | Donna Dawson/Charles E. Meyer SWRO Desalination plant

At this point, the clarified seawater hits high-pressure pumps that push it into the RO membranes at 900 psi. As clear water exits the RO modules, its chemistry is adjusted in a post-treatment process, and the resulting potable product water is pumped directly into the city’s water distribution system for delivery to customers.

As is the case at the Carlsbad plant, of the 6 million gallons per day of seawater brought into the Santa Barbara system, half is turned into drinking water and half is discharged as salt-saturated seawater (brine), which eventually is mixed with 6 million gallons per day of treated wastewater on its way back to the ocean. “By the time it is released offshore, the discharge is roughly equal in salinity to the surrounding seawater,” Haggmark says.

Santa Catalina Island. On the Island of Catalina, just off the coast of southern California (Fig. 6), Southern California Edison (SCE, Rosemead, Calif.) owns and operates two SWRO plants at Pebbly Beach, which together can produce about 325,000 gallons of drinking water per day (0.325 million gallons per day), serving 4,000 residents and about 1 million visitors a year. Plant 1 was originally brought online in 1990 during a severe drought, but was deactivated when heavy rain refilled groundwater supplies. It was put into operation again in 2003 during another period of drought and to “support compliance with changing water quality standards,” explains Ron Hite, SCE’s island manager.

Fig. 6 Southern California Edison (SCE) is the owner-operator of two SWRO plants at Pebbly Beach on the Island of Santa Catalina. The plants can produce about 325,000 gallons of drinking water per day, serving 4,000 residents and 1 million visitors a year. Source | SCE

Plant 1’s RO process relies on 20 filament-wound FRP, 8-inch diameter, 1,200-psi pressure vessels made by Fluid Systems in San Diego, according to Randy Truby, who was director of marketing for Fluid Systems in the early 1990s and CEO from March 1997 until June 1998. Fluid Systems sold its pressure vessel business to Codeline (now Pentair-Codeline) in the mid-1990s and sold its membrane business to Koch Industries in June 1998, he says. (Truby was CEO of TMUS when he retired in October 2010.)

Fig. 7 Plant 1 (top) and Plant 2 (below) in Catalina together run 32 pressure vessels housing 144 RO membrane modules in its SWRO system. Source | SCE

“The pressure vessels for the Catalina plant were contracted by Village Marine (Hawthorne, Calif.), which built the SWRO system for Catalina incorporating Dow Filmtec membrane modules,” Truby explains. Now owned by Parker Hannifin, Parker Village Marine (VMT, Carson, Calif.) continues to develop advanced water desalination and purification systems worldwide.

Plant 2 was constructed in 2016 to provide incremental desalinated water capacity in response to prolonged drought conditions. Plant 2 runs 12 E-glass epoxy pressure vessels supplied by Pentair Codeline (Golden Valley, Minn., U.S. and Twickenham, London, U.K.), Model 80S 120, manufactured by filament winding at Pentair’s Goa, India, plant. Certified for 1,200 psi, each pressure vessel houses seven RO membranes. A worldwide brand since 1976, Pentair Codeline has more than 600,000 pressure vessel membrane housings in service globally for various applications, including SWRO. The pressure vessels were installed at Catalina’s SWRO facility as part of General Electric’s SeaTech*-84 modular SWRO system, a containerized desalination system developed for GE’s Procera seawater desalination solutions (GE, Boston, Mass.). GE sold its GE Water & Process Technologies business to SUEZ SA (Paris, France) in September 2017.

The two plants are typically run individually, depending on the island's fluctuating demand.

Seawater is pumped into the system through an 8-inch diameter HDPE pipe about 5,000 feet long, from two beach wells at the island’s rock quarry. The seawater is drawn from an underground aquifer that is directly connected to the ocean, Hite says. “There is no open ocean intake and therefore no associated concern for impact to marine life.” Similarly, due to the low volume of discharge, no discharge pipeline is required. “The discharge water simply overflows across the shoreline rip rap [rock retaining walls], dispersing the concentrated brine before mixing with the tidal waters,” Hite explains.

SCE has applied to the state of California for funding assistance to further develop SWRO on Catalina, Hite adds. “The funding would allow SCE to double production capacity and increase storage capacity by about 25 times. This would position Catalina to likely avert any mandatory rationing for the foreseeable future.

Importance of solving California’s water shortages

The core challenge for the water situation in California rests on the fact that the amount of water on Earth is finite. Traditional sources of water — lakes, river, streams — are either tapped out or soon will be. And as populations increase, it’s incumbent on water providers to seek water elsewhere. As Sandy Scott-Roberts, program manager for the Orange County Water District (OCWD) Ground Water Replenishment System (GWRS, Fountain Valley, Calif.), explains: “There has never been new water on our Earth. We have had the same volume of water for millions of years.” And most of that is not safe to drink.

Paul Kelley, former executive director for CalDesal, puts it this way: “We are living on the infrastructure of our forefathers.” CalDesal (Sacramento, Calif.) is a non-profit association that promotes use of desalination to help meet California's water-supply challenges. Further, Kelley notes, “California is the breadbasket of the world.” Indeed, more than a third of the country's vegetables and two-thirds of the country’s fruits and nuts are grown in California, according to the California Department of Food & Agriculture (CDFA, Sacramento). Globally, California accounts for more than 13% of the nation's total agricultural value and nearly 15% of total U.S. agricultural exports — including 100% of exported tree nuts, artichokes and garlic.

Kelley continues: “We have a responsibility to update and improve our infrastructure to make ourselves more water resilient, but also recognize the necessity of improving the environment while still feeding our people.”

Poseidon, which operates the Carlsbad SWRO plant, has its own commitment to this responsibility. Poseidon's Maloni points out that “many of California’s existing challenges, including severely depleted groundwater aquifers and uncertain water supplies, stem from the need for a new, reliable and sustainable water resource.”

Fig. 8 Poseidon is in the final phase of the permitting process for a Huntington Beach SWRO facility designed to produce 50 million gallons per day of drinking water, using advanced seawater intake and discharge technologies to protect the marine environment — and the people who share it. Source | Poseidon

Opportunities — and challenges — for further expansion

Community acceptance and permitting is slow in California, in part due to concerns about the marine environment. These concerns have not proven to be warranted, though. Santa Barbara's Haggmark says, “Desalination is not the environmental disaster that its opponents make it out to be. There are thousands of desalination plants around the world and the data just doesn’t support the accusations.”

Poseidon’s Maloni notes that “California has some of the most stringent environmental laws and regulations in the world and the successful three-year operation of the Carlsbad desalination plant proves that large-scale seawater desalination plants can be sited, designed, built and operated in California without significant impacts to the environment.”

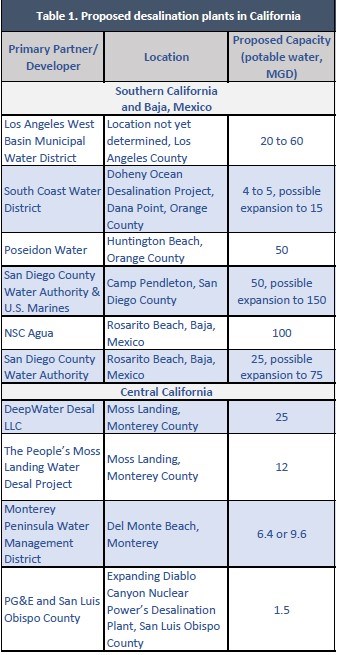

Table 1. This is a list of 10 proposed desalination plants for California as of summer 2015, identified by Heather Cooley, director of research for the Pacific Institute in Oakland, Calif., a global water think tank for promoting sustainable water policy solutions. Cooley sees SWRO as one option for meeting California’s water needs, but considers other options — notably water conservation and efficiency, storm water capture and water reuse — to be more cost-effective. Composites industry sources agree that water reuse/wastewater recycling is less expensive and not as technically demanding compared to SWRO.

Although there are currently only three SWRO plants active in California, there is room for more. Poseidon is in the final phase of the permitting process for a Huntington Beach (Calif.) SWRO facility designed to produce 50 million gallons per day of drinking water. The proposed project will be 100% carbon neutral, and the facility will use state-of-the-art seawater intake and discharge technologies that avoid and minimize marine life effects.

Beyond Huntington Beach, there are 10 proposed SWRO plants in the queue in California (Table 1). These range in capacity from 295 to 498 million gallons per day. It’s probably not realistic to expect that they will all be built out, especially since some are competing projects. However, it is encouraging to know that so many are in consideration. If most or even some of them were constructed and in operation, it would be a positive step toward resolving California’s water crisis, as well as value-added for fiberglass composite materials and process suppliers.

Global success and importance of SWRO

Seawater desalination isn't just limited to California or the U.S. Global success of desalination is well established by the Water Security Handbook, published in January 2019 by the International Desalination Association (IDA, Topsfield, Mass., U.S.). IDA's statistics show that total global installed desalination capacity stands at 97.4 million cubic meters per day (25.7 billion gallons per day), while the total global cumulative contracted capacity — representing contracts that have been signed and are in place for constructional additional plants — is 104.7 million cubic meters per day (27.7 billion gallons per day). As of June 2018, more than 20,000 desalination plants had been contracted around the world. The largest global seawater desalination plant currently under construction is a 378,000 cubic meters per day (nearly 100 million gallons per day) project in Rosarito, Mexico, which is expected to begin construction in early 2020.

Related Content

Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreComposites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

Read MoreWatch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More